+86 755 2794 4155

+86 755 2794 4155  sales@knownpcb.com

sales@knownpcb.com

-

Shenzhen KNOWNPCB Technology Co., Ltd.

+86 755 2794 4155

+86 755 2794 4155  sales@knownpcb.com

sales@knownpcb.com

2025-07-08

2025-07-08

865

865

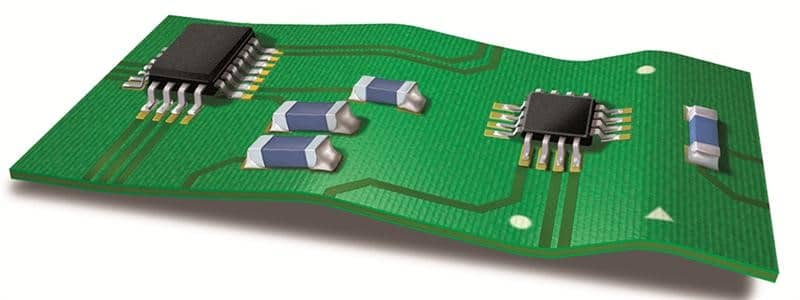

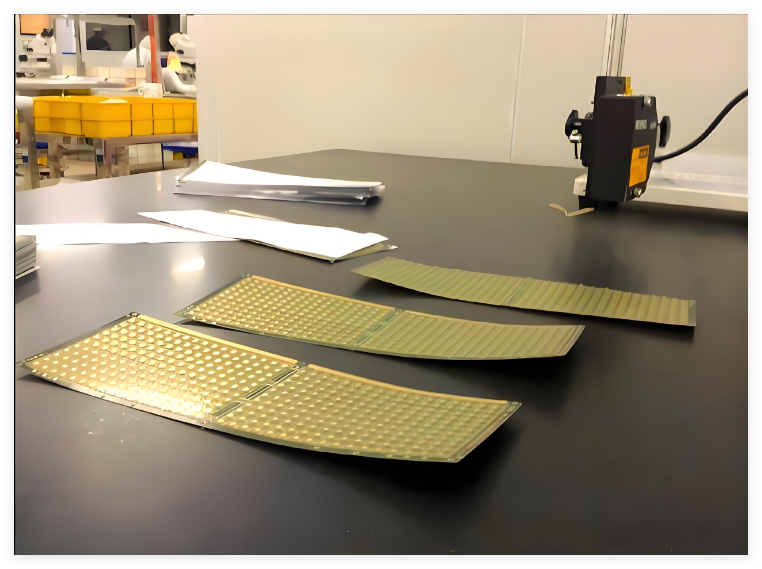

Warpage refers to the phenomenon that the plane of the PCB is bent or deformed due to various reasons during the manufacturing, storage or use of the PCB. This deformation may be local or overall, and is usually manifested as the PCB no longer remaining flat.

Causes of PCB Warping

•Improper wiring design

If the wiring direction on the PCB is inconsistent, it will cause different stresses in different directions. For example, when designing high-speed digital circuits, if the wiring direction is messy, different signal transmission delays and impedance changes may occur in different directions, causing uneven stress and PCB warping.

•Improper selection of substrate materials

The thickness and strength of the substrate material will also affect the warping of the PCB. If the substrate material is too thin or not strong enough, it is easy to deform and warp when subjected to external force or temperature changes. On the contrary, if the substrate material is too thick or too strong, it may make the PCB difficult to process during the manufacturing process and may also increase the risk of warping.

•Poor copper foil quality

If the copper thickness is uneven, it will cause different thermal conductivity in different areas of the PCB, resulting in uneven temperature distribution, stress difference, and PCB warping.

If the adhesion between the copper foil and the substrate is not strong, the copper foil may peel off the substrate under conditions such as temperature changes or mechanical vibrations, causing PCB warping.

•Unreasonable production process

During the manufacturing process of the PCB, different processing techniques have different sequence requirements. If the processing sequence is improper, it may cause uneven stress distribution inside the PCB, causing warping.

Adverse effects of PCB warping

•Impact on the installation of electronic components

Components installed on warped PCBs may be subject to uneven stress, which may affect the welding quality of components and increase the risk of welding defects such as cold soldering and desoldering.

•Impact on electrical performance

Match cure profile to resin chemistry. Proper ramp and dwell avoid stress and voids. PCB warping may cause changes in the length and spacing of lines on the PCB, thereby changing the impedance characteristics of the circuit. This may cause delay, attenuation and distortion of signal transmission, reducing the quality and integrity of the signal.

•Impact on equipment accuracy and performance

For some electronic products with high precision requirements, such as medical equipment, aerospace equipment, etc., PCB warping may affect the overall accuracy and performance of the equipment.

•Impact on reliability and life

Since warping will cause uneven stress on components on the PCB, long-term use may cause fatigue damage and failure of components.

In summary, PCB warping is an issue that needs to be highly valued, which may have many adverse effects on the production and use of electronic products. Understanding the causes, effects and coping strategies of PCB warping is crucial to improving the quality and reliability of electronic products.

Or call +86 755 2794 4155

Inquiry Now