+86 755 2794 4155

+86 755 2794 4155  sales@knownpcb.com

sales@knownpcb.com

-

Shenzhen KNOWNPCB Technology Co., Ltd.

+86 755 2794 4155

+86 755 2794 4155  sales@knownpcb.com

sales@knownpcb.com

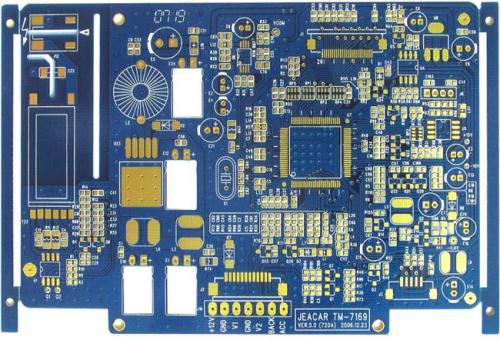

I. The backlight is unstable, and the hole wall is without copper

1. The composition of chemical copper working liquid is out of control or the process conditions are out of control

2. The adjuster is missing or invalid

3. Low activator component or temperature

4. Overspeed

5. Different plates, to drill dirt is too strong

6. The inner layer of the hole wall is broken or peeled off when drilling

So how do circuit board manufacturers improve it?

1. The composition and process conditions of the whole working liquid, especially increasing the content of HCHO, appropriately increasing the temperature or reducing the addition of components containing stabilizers, improve the activity of the working liquid.

2. Add or replace the regulator at normal temperature

3. Add activator and increase the temperature

4. Reduce the concentration of accelerant or immersion time

5. Appropriately reduce the decontamination strength, and improve the activity of activator and chemical copper solution

6. Improve the quality of drill, plate and blackening treatment

Read recommendations:

6L Gold finger 30U" BGA pitch 0.4mm

Appointment Experience