+86 755 2794 4155

+86 755 2794 4155  sales@knownpcb.com

sales@knownpcb.com

-

Shenzhen KNOWNPCB Technology Co., Ltd.

+86 755 2794 4155

+86 755 2794 4155  sales@knownpcb.com

sales@knownpcb.com

Have you noticed that now more and more of our lighting is using led lighting.What is LED? Compared to the traditional light bulbs, LEDs have lower power consumption, longer lifetime and higher energy efficiency. In the PCB industry,when we say LED PCB, it refers to the pcb used for LED lighting, if you are looking for a suitable LED PCB for your lighting system, this article may bring you something. WHAT ARE LEDS COMPOSED OF?LED is an initial light-emitting diode that produces light when an electric current passes through. LEDs typically have negative and positive electrodes, which generate light in the visible light region.The LEDS are glued to the PCB by soldering process and have electrical connections for lighting.Since light-emitting diodes dissipate a lot of heat when they are in use, when you are designing LED, the metal core is usually the best choice for LED PCB, it is because that it dissipates heat more faster. Among them, the metal material aluminum is the most widely used

KnownPCB provides one-stop PCB and PCBA solution from PCB design, DFMA analysis, PCB manufacturing, SMT placement, to terminal DIP plug-ins.No Min.Qty's required.

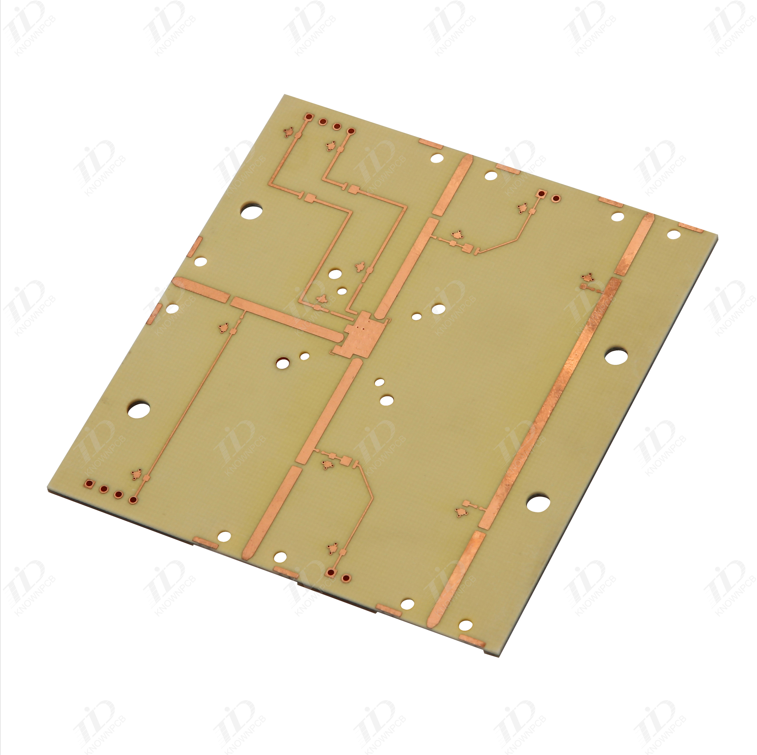

With the rapid advancement of electronic communication technology, the demand for high-frequency circuit boards in communication equipment has significantly increased to support high-speed and high-frequency signal transmission. These boards utilize dielectric materials that exhibit exceptional electrical properties and outstanding chemical stability.

Drilling of PCB board is one of the crucial processes in PCB manufacturing, and the quality of this drilling directly affects the performance and reliability of the entire PCB board.Next, let's discuss some of the key factors that affect the drilling quality of PCB boards.

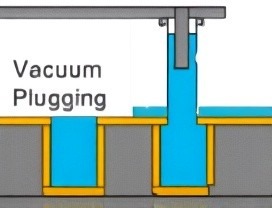

Resin plugging is a process that fills vias or through-holes with insulating resin, then cures it to create a flat, sealed surface. This enhances layer bonding, supports high-density interconnects, and improves reliability.Compared to solder mask plugging, resin ensures better sealing and thermal stability.

Aging tests for printed circuit boards (PCBs) are essential procedures aimed at evaluating the long - term reliability and performance of PCBs under various stress conditions. These tests simulate the effects of extended usage, environmental factors, and electrical loads that PCBs may encounter during their operational life, helping manufacturers and engineers identify potential failures and improve product quality. One of the most common aging test methods is thermal aging. In this method, PCBs are exposed to elevated temperatures for an extended period. Typically, the temperature is set well above the normal operating temperature, often ranging from 85°C to 150°C, depending on the application and the materials used in the PCB. The high - temperature environment accelerates the degradation processes within the PCB, such as the oxidation of metal traces, the deterioration of solder joints, and the thermal expansion and contraction of different materials. By monitoring the PCB'

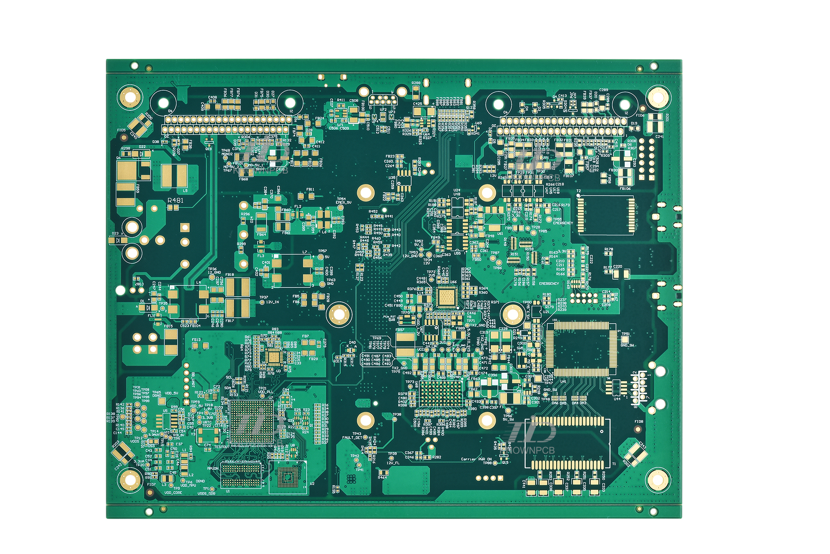

High-Density Interconnector (HDI) PCBs are advanced printed circuit boards characterized by a higher wiring density per unit area compared to standard PCBs. They incorporate fine lines, microvias, and often multiple layers, which allow for more compact and efficient designs.

Printed Circuit Board (PCB) impedance testing is a critical process in PCB design and manufacturing, playing a fundamental role in ensuring the reliable operation of electronic circuits. Impedance refers to the opposition that a circuit presents to the flow of alternating current (AC), and it is a key parameter that affects signal integrity in high - speed digital and analog circuits. In high - speed digital circuits, maintaining proper impedance control is essential. As data transfer rates increase, signals travel at higher frequencies, and factors such as signal reflections, crosstalk, and attenuation become more pronounced. If the impedance of the PCB traces is not properly matched to the impedance of the connected components (such as integrated circuits), signal reflections occur when the signal reaches the end of the trace or encounters a change in impedance. These reflections can cause the signal to distort, resulting in errors in data transmission, such as bit - errors in d

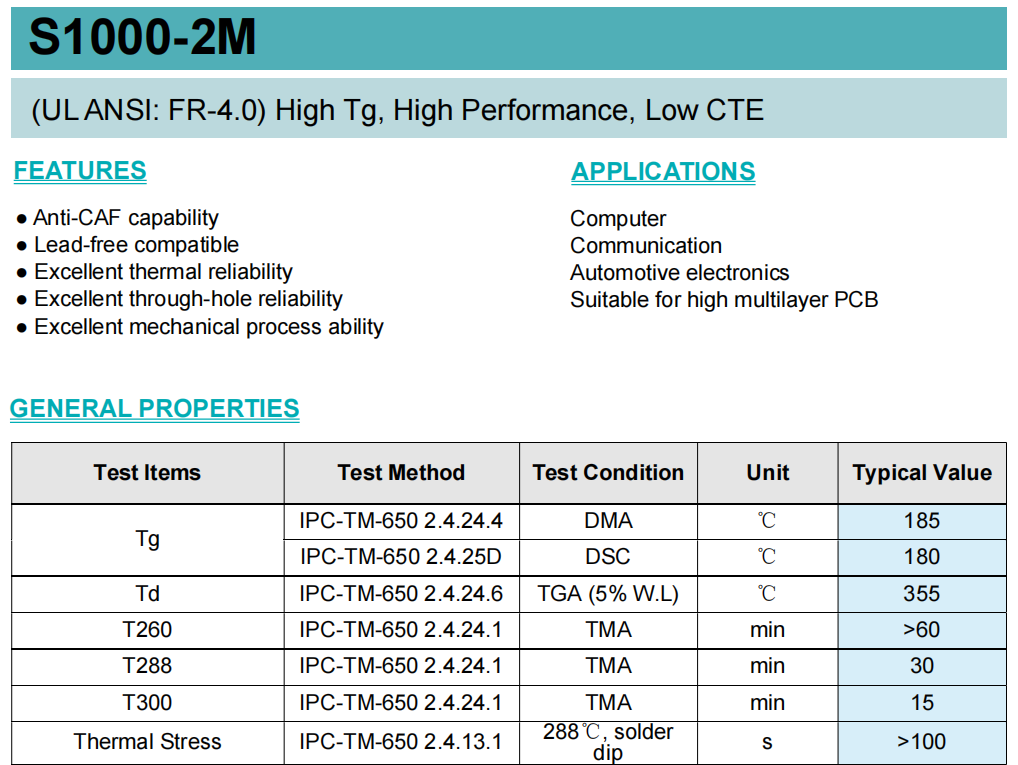

Relationship between PCB high-TG materials and copper foilUnderstanding Glass Transition Temperature(TG ) The glass transition temperature of a PCB board is a key indicator for measuring its performance. When the temperature rises to a certain level, the PCB substrate will transition from a "glass state" to a "rubber state". The higher the TG value, the better the temperature resistance of the PCB, and its performance such as heat resistance, moisture resistance, chemical resistance, and resistance stability is also better.The distinction between standard FR-4 and high-Tg FR-4 In the hot state, especially when heated after moisture absorption, there are differences in the mechanical strength, dimensional stability, adhesion, water absorption, thermal decomposition, thermal expansion, and other aspects of the material. High-Tg FR-4 substrates demonstrate superior performance across these critical parameters compared to standard-Tg counterparts.Why can't standard-Tg and h

Heavy copper PCBs have high current-carrying and thermal conductivity, with wide industrial use, but face manufacturing/cost/design challenges needing specific guidelines.

The Sino - US trade situation has been a topic of global concern, and its implications span across numerous industries. The Printed Circuit Board (PCB) industry, a fundamental part of the electronics value chain, is no exception. The relationship between Sino - US trade and the PCB industry is complex, with various factors at play that can influence the industry's growth, market dynamics, and competitive landscape. Direct Impact on Trade Volumes One of the most immediate aspects to consider is the direct effect on trade volumes. China is a dominant force in the global PCB market, accounting for over 50% of the world's production capacity. The United States, on the other hand, is a major consumer of electronics products that rely on PCBs. When trade tensions rise, such as the imposition of tariffs, it directly impacts the cost of PCB products traded between the two countries. For instance, during the previous rounds of Sino - US trade disputes, the US imposed tariffs on a range o

The gold finger possess excellent electrical conductivity, ensuring efficient signal and current transmission. Additionally, it offer strong corrosion resistance, effectively withstanding oxidation and corrosion. Lastly, they exhibit robust mechanical strength, capable of enduring insertion, removal, and pressure.

In the era of 5G technology, 5G PCB (Printed Circuit Board) boards play a pivotal role in ensuring the seamless operation of high - speed communication devices. These boards are the unsung heroes behind the functionality of 5G smartphones, base stations, and other related equipment. Design and Complexity 5G PCB boards are engineered with a high degree of complexity. They need to accommodate a large number of components, including high - frequency chips, filters, and connectors. The design must consider factors such as signal integrity, impedance matching, and electromagnetic interference (EMI). To meet the high - speed data transmission requirements of 5G, PCB manufacturers use advanced design techniques. For example, they often employ multi - layer designs, which can stack multiple conductive layers separated by insulating materials. This allows for a more compact layout and better management of complex circuits. High - Frequency Performance One of the most critical aspects of

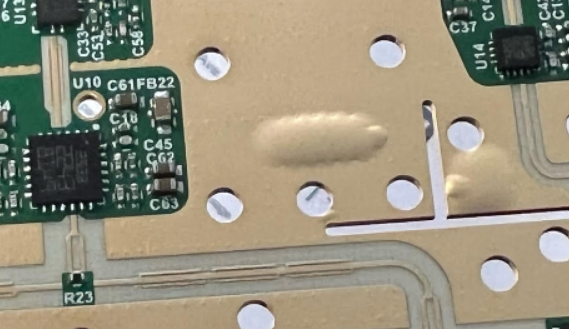

PCB blistering is primarily caused by defects in the electroless copper plating and electroplating processes during circuit board manufacturing, representing one of the most prevalent quality issues. The root cause of board surface blistering fundamentally stems from poor adhesion (interfacial bonding failure) or surface quality defects on the copper-plated layer.

PCB (Printed Circuit Board) reliability test is crucial for ensuring the performance and durability of electronic devices. These tests are designed to evaluate the ability of PCBs to withstand various environmental and operational stressors over time. One of the key aspects of PCB reliability testing is thermal stress testing. This involves subjecting the PCB to extreme temperatures, both high and low, to simulate the conditions it may encounter in different applications. For example, a PCB in an automotive engine compartment may be exposed to high temperatures, while a PCB in an outdoor telecommunications equipment may experience extreme cold. By testing the PCB under these temperature extremes, potential weaknesses such as delamination, solder joint failures, and component degradation can be identified. Another important reliability test is mechanical stress testing. This includes vibration testing, shock testing, and bend testing. Vibration testing simulates the effects of mec

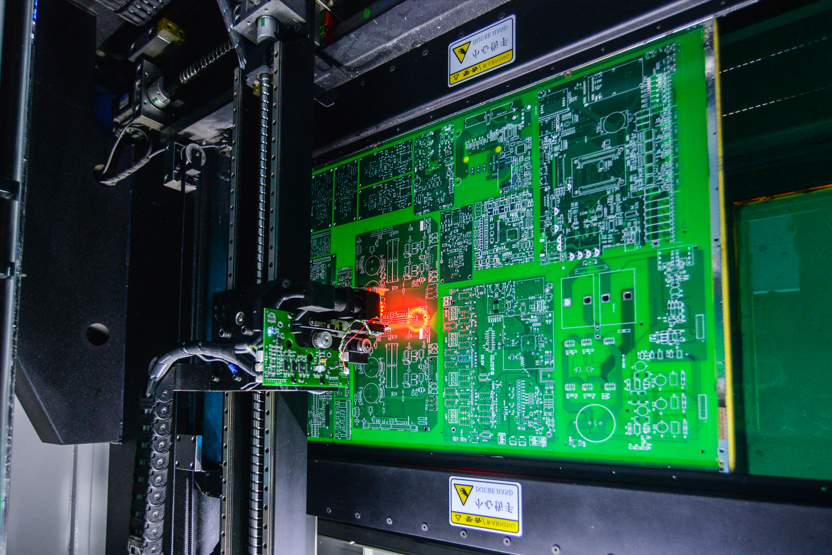

Manufacturing Process Precision Manufacturing Techniques High - frequency PCBA boards require highly precise manufacturing processes. The drilling of vias, which are used to connect different layers of the board, needs to be extremely accurate. The diameter of the vias and their placement must be within tight tolerances to avoid any impact on the signal integrity. Laser drilling is often used in the manufacturing of high - frequency PCBA boards as it can achieve very small via diameters with high precision. The soldering process also needs to be carefully controlled. In high - frequency applications, poor soldering joints can introduce impedance mismatches and signal reflections. Advanced soldering techniques, such as reflow soldering with precise temperature control, are used to ensure reliable and high - quality solder connections. For example, in the assembly of high - speed data transfer PCBA boards, the soldering of high - speed connectors and integrated circuits is crucial

This article introduces several factors that affect the price of PCB.By understanding these factors, you can make more informed decisions when budgeting for PCB production.

Understanding Vias holes (According to IPC-4761),Next, we will provide a introduction to Tent Via (Type I Via),Tented and Covered Via (Type II Via),Plugged Via (Type III Via),Plugged and Covered Via (Type IV Via),Filled Via (Type V Via),Filled and Covered Via (Type VI Via),Filled and Capped Via (Type VII Via).

The price trend of PCBs (Printed Circuit Boards) is influenced by multiple factors, showing a complex and changeable situation. In recent years, the price of PCBs has generally trended upward. One of the main reasons is the fluctuation in raw material prices. PCBs mainly consist of copper foil, resin, glass fiber, and other materials. In the past few years, due to the booming lithium and new - energy automotive industries globally, the demand for copper has increased sharply, leading to a continuous rise in copper prices. As the main raw material of PCBs, the price increase of copper foil has directly driven up the production cost of PCBs. In addition, the prices of gold, silver, tin, and other precious metals, which are core components of PCBs, have also continued to rise, further increasing the cost of raw materials. Moreover, labor costs have been on the rise. With the improvement of living standards and the increase in labor protection requirements, the wage levels of workers

In the realm of modern electronics, PCB play a crucial role. They provide the physical and electrical infrastructure for connecting and supporting electronic components, allowing them to interact and function as intended. Without PCB, our electronic devices would be a chaotic mess of individual components with no way to communicate or work together.

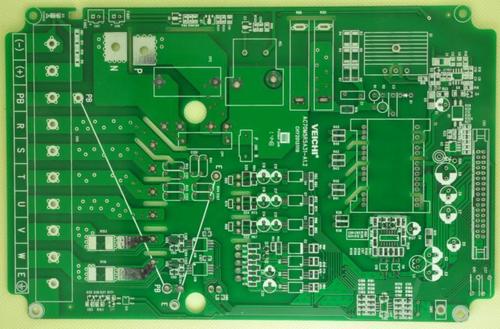

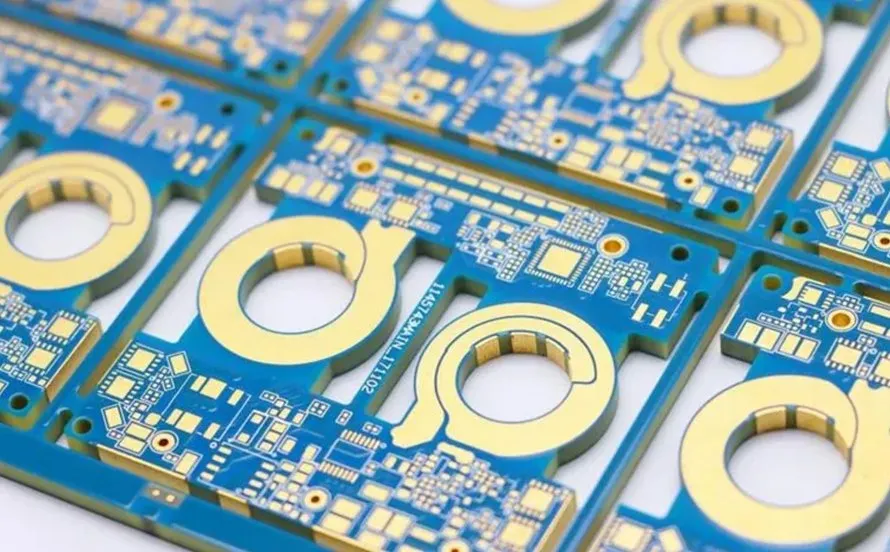

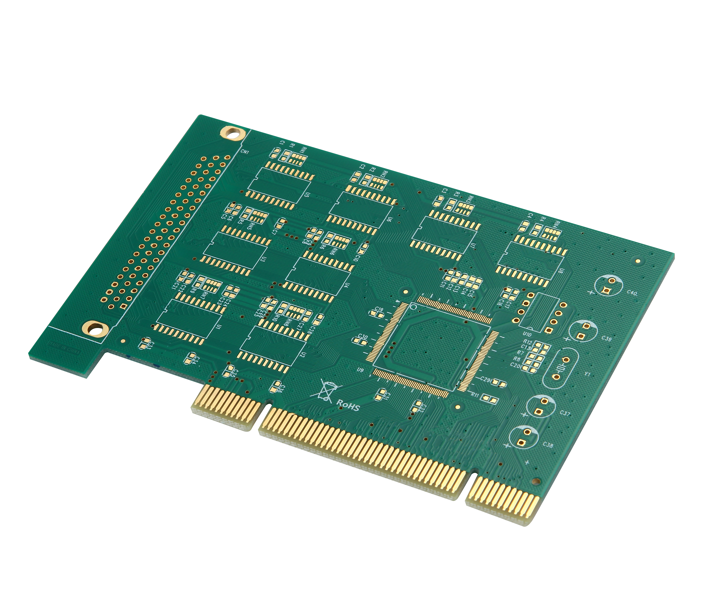

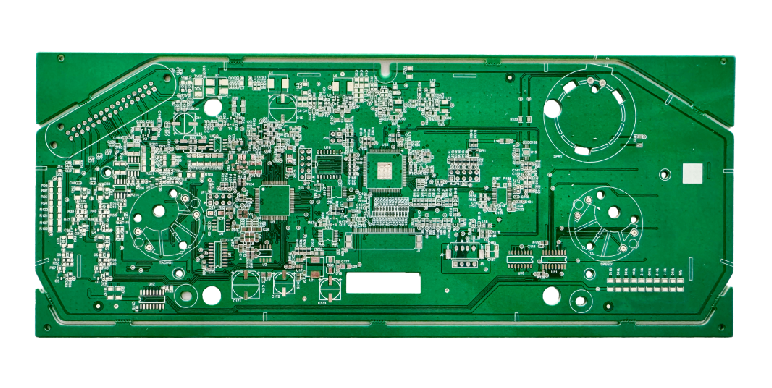

Introduction forThe Automotive Board and The Communication Board.

Inquiry Now