+86 755 2794 4155

+86 755 2794 4155  sales@knownpcb.com

sales@knownpcb.com

-

Shenzhen KNOWNPCB Technology Co., Ltd.

+86 755 2794 4155

+86 755 2794 4155  sales@knownpcb.com

sales@knownpcb.com

2025-04-30

2025-04-30

298

298

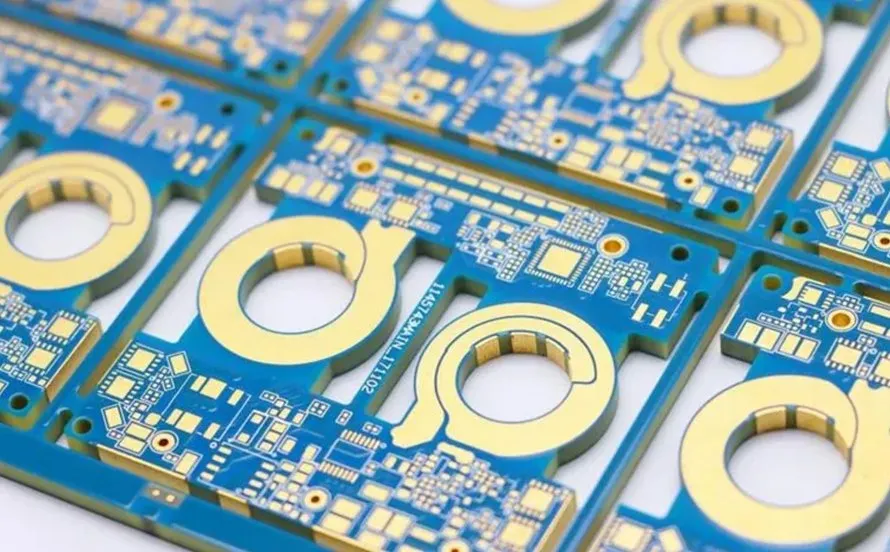

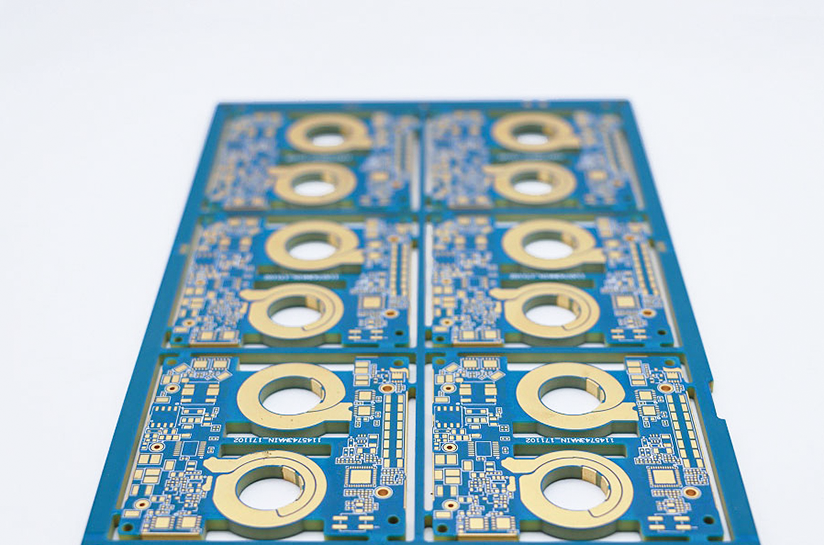

Heavy copper PCBs have high current-carrying and thermal conductivity, with wide industrial use, but face manufacturing/cost/design challenges needing specific guidelines.

Heavy copper PCB’ Advantages

•High Current Carrying Capacity

Heavy copper PCBs (e.g., 3oz, 4oz) have a larger cross-sectional area, enabling them to handle higher currents. This makes them ideal for high-power applications such as power modules, motor drives, and electric vehicles, reducing heat generation and voltage drop.

•Superior Thermal Performance

Copper's excellent thermal conductivity allows thick copper layers to act as heat dissipation paths, effectively spreading heat from components and reducing the need for additional heat sinks.

•High-Temperature Resistance

Heavy copper PCBs are more durable in high-frequency or high-temperature applications, reducing the risk of burnout due to current overload.

•Enhanced Mechanical Strength

Heavy copper layers improve PCB rigidity, minimizing deformation caused by thermal expansion or mechanical stress.This makes them suitable for harsh environments, such as industrial equipment and aerospace applications.

•Reduced Layer Count Requirement

In high-current circuits, heavy copper can replace multilayer designs, simplifying structure and lowering costs.

Heavy copper PCB’ Disadvantages

•Higher Manufacturing Difficulty

Etching thick copper requires precise process control, as issues like undercutting or uneven traces may arise, leading to lower yield rates.

•Increased Cost

Higher copper material costs and the need for specialized equipment (e.g.,electroplating for thickness) drive up production expenses.

•Design Complexity

Heavy Copper is less compatible with fine-pitch traces,requiring wider trace widths and spacing, which limits high-density routing.

•Added Weight

The increased copper thickness significantly raises PCB weight, making it less suitable for portable devices like drones and consumer electronics.

•Impedance Control Challenges

In high-frequency signal transmission, Heavy copper can affect impedance matching, requiring additional design adjustments(e.g., reference layer optimization).

Applications Fields

•Automotive

Used in EV motor controllers, power supplies, battery management systems, and internal electronics for higher durability and better thermal performance.

•Power Electronics

Applied in power supplies, converters, and inverters to handle high currents and improve heat dissipation.

•Aerospace and Defense

Enhances the reliability and lifespan of electronics exposed to harsh environments, such as avionics, communication, and radar systems.

•Renewable Energy

Ideal for solar inverters and wind turbine controllers due to high power handling and thermal management.

•Medical Electronics

Used in imaging devices, patient monitoring systems, and diagnostic instruments requiring high reliability.

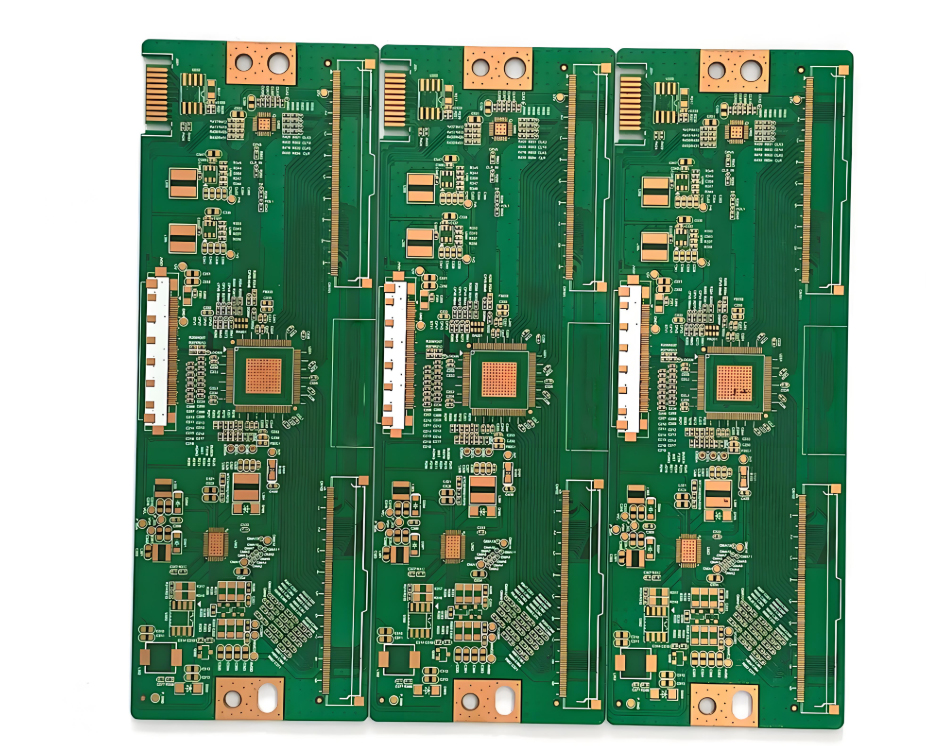

•High-Performance Computing

Manages extreme heat in data centers and HPC systems, improving durability and performance.

•Industrial Automation

Supports high current and high voltage operations in heavy machinery, ensuring stable industrial production.

Or call +86 755 2794 4155

Inquiry Now