+86 755 2794 4155

+86 755 2794 4155  sales@knownpcb.com

sales@knownpcb.com

-

Shenzhen KNOWNPCB Technology Co., Ltd.

+86 755 2794 4155

+86 755 2794 4155  sales@knownpcb.com

sales@knownpcb.com

2023-09-19

2023-09-19

142

142

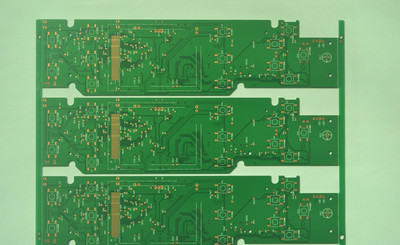

Module half hole PCB board. A double-layer PCB circuit board is a type of PCB circuit board formed by bonding a replaced conductive pattern layer and an insulating layer material layer. The number of stacked layers of the conductivity pattern is above three, and the interconnection of fixed layer electrical equipment is completed based on metallized holes. If one double-sided board is used as the inner layer, two single-sided aluminum substrates are used as the outer layer, or two double-sided boards are used as the inner layer, and two single-sided aluminum substrates are used as the outer layer, and the raw materials are bonded together according to the system and insulation layer, and the conductivity pattern is interconnected according to the design plan, it becomes a four or six layer PCB circuit board, also known as a double-layer PCB circuit board.

A double panel is a material layer in the middle, and both sides are wiring layers. The double-layer module half hole PCB board is a double-layer wiring layer, with a material layer in the middle of each layer, which can be made very thin. A double-layer circuit board has at least three conductive layers, with the two layers on the outer surface and the remaining layer generated inside the anti-static rubber. The protective grounding between them is generally completed based on the plating holes on the cross-section of the circuit board.

The production process of PCB circuit boards is generally divided into three types: single-sided, double-sided, and solid wood multi-layer boards. The names of processing plants with different production processes vary, but the basic principles of the production process are the same!

1. The production process of single sided aluminum substrate is much easier to understand than the steps of double-sided board, with the foundation being cutting, punching, pattern migration, etching, anti welding and marking of identifiers, metal surface solution, finished product forming, testing, packaging and delivery.

2. The overall steps in the production and manufacturing of double-sided boards are: cutting, punching, chemical copper deposition and electroplating process - copper, pattern migration, pattern electroplating process and tin plating maintenance, etching processing, center inspection, anti welding, marking, metal surface solution, finished product forming, electrical inspection, appearance inspection, packaging and delivery.

3. The steps of a double-layer module half hole PCB board are to add an inner layer process flow before the steps of a double-sided board. The basic steps include material cutting, inner layer pattern migration, inner layer etching processing, inner layer etching processing inspection, copper surface air oxidation, layout design and stacking, pins, cutting and forming, followed by the double panel production process.

Or call +86 755 2794 4155

Inquiry Now