+86 755 2794 4155

+86 755 2794 4155  sales@knownpcb.com

sales@knownpcb.com

-

Shenzhen KNOWNPCB Technology Co., Ltd.

+86 755 2794 4155

+86 755 2794 4155  sales@knownpcb.com

sales@knownpcb.com

Have you noticed that now more and more of our lighting is using led lighting.What is LED? Compared to the traditional light bulbs, LEDs have lower power consumption, longer lifetime and higher energy efficiency. In the PCB industry,when we say LED PCB, it refers to the pcb used for LED lighting, if you are looking for a suitable LED PCB for your lighting system, this article may bring you something. WHAT ARE LEDS COMPOSED OF?LED is an initial light-emitting diode that produces light when an electric current passes through. LEDs typically have negative and positive electrodes, which generate light in the visible light region.The LEDS are glued to the PCB by soldering process and have electrical connections for lighting.Since light-emitting diodes dissipate a lot of heat when they are in use, when you are designing LED, the metal core is usually the best choice for LED PCB, it is because that it dissipates heat more faster. Among them, the metal material aluminum is the most widely used

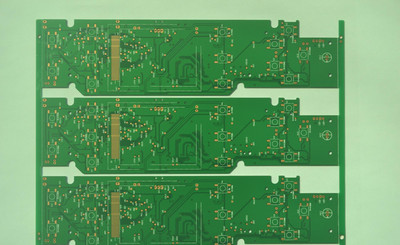

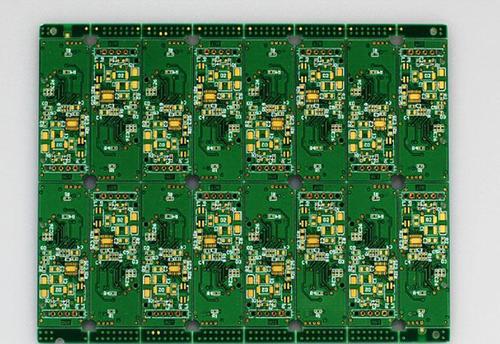

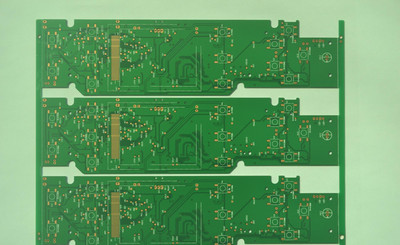

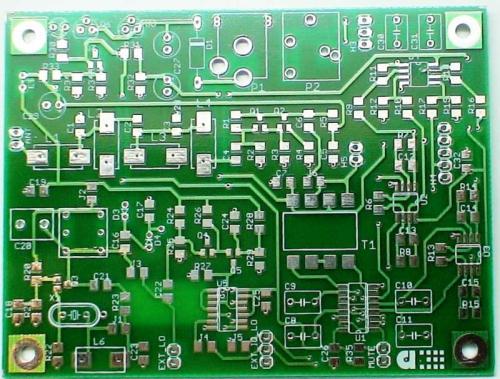

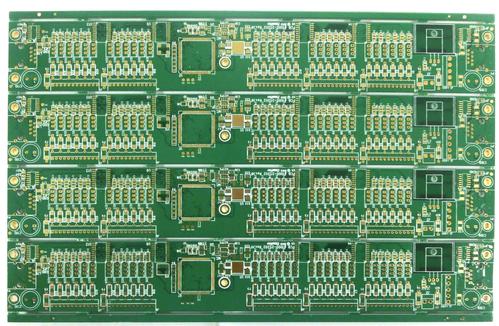

There are many types of circuit boards with different names, which can be named based on materials, layers, inherent characteristics, and other aspects. For example, there are: single panel, double-sided board, multi-layer board, HDI, fast board, FR4 circuit board, ceramic circuit board, alumina ceramic circuit board, aluminum nitride ceramic circuit board, circuit board, PCB board, aluminum substrate, high-frequency board, thick copper board, impedance board, PCB, ultra-thin circuit board, ultra-thin circuit board, Printing (copper etching technology) circuit boards, etc. Circuit boards are miniaturized and intuitive, playing an important role in the mass production of fixed circuits and optimizing the layout of electrical appliances Printed circuit boards (PCBs) are essential accessories in modern electronic equipment. All electronic devices, whether they are large machinery, personal computers, communication base stations, mobile phones, household appliances, or electronic toys

The video measurement system is suitable for measuring prismatic workpieces with intersecting planes. When planes intersect, edges appear, and videos can easily measure edges. Orthopaedic transplantation components are usually composed of continuous and regular curves (artificial hip joint fittings) or complex contour surfaces (artificial knee joint fittings), whose shape is just like the contour of human organ. These surfaces have few or no flat or intersecting edges. Although video sensors are good at measuring edges and surface points, using a large number of data points to obtain data on even linear cross-sections of contour surfaces is very laborious and impractical. Trigger probes also have the same limitations, as they need to approach each point and return to the plateau after triggering - although feasible, they are also not suitable for measuring large quantities of products. The best method to determine whether the bionic curve contour of artificial knee joint meets th

In addition to the wiring on the substrate, the metal coating is the place where the substrate line and electronic component are welded. In addition, different metals also have different prices, and different ones will directly affect the cost of production. Different metals also have different weldability and contact, as well as different resistance values, which will directly affect the effectiveness of the component. Common metal coatings include: copper tin The thickness is usually 5 to 15 μm Lead tin alloy (or tin copper alloy) That is welded, the thickness is usually 5 to 25 μm, and the tin content is about 63% gold Generally only plated in the interface silver Generally, it is only placed in the interface, or the alloy of silver with the whole

Because it is made of electronic printing technology, it is called a "printing" circuit board. Before the emergence of the printed circuit board, the interconnection between electronic components rely on the wires to directly connect to form a complete line. Circuit bread boards exist only as effective experimental tools, and the printing circuit board has become an absolute dominance in the electronics industry. At the beginning of the 20th century, in order to simplify the production of electronic machines, reduce the wiring between electronic parts, and reduce the advantages of production costs, they began to study the method of replacing the wiring by printing. In the past thirty years, engineers have continued to propose a metal conductor on the insulating substrate as a wiring. The most successful is that in 1925, Charles Ducas in the United States printed out line patterns on the insulated substrate, and successfully established a conductor to wiring in an electroplating.

The substrate is generally classified as the insulation part of the substrate. The common raw materials are electric wood plates, glass fiber plates, and various types of plastic plates. The PCB manufacturers generally use an insulating part of glass fiber, non -fabrics, and resin, and then suppressed in epoxy resin and copper foil as "Prepreg". The common substrates and main ingredients are: FR-1-phenolic cotton paper, this substrate is commonly referred to as electric wooden boards (higher economy than FR-2) FR-2 ─ Phenolin cotton paper, FR-3-Cotton Paper, epoxy resin FR-4-Woven Glass, epoxy resin FR-5-glass cloth, epoxy resin FR-6-f f f, polyester G-10-glass cloth, epoxy resin CEM-1-cotton paper, epoxy resin (flame retardant) CEM-2-cotton paper, epoxy resin (non-flame retardant) CEM-3-glass cloth, epoxy resin CEM-4-glass cloth, epoxy resin CEM-5-glass cloth, polyester Ain -aluminum nitride SIC -silicon carbide

It is important to develop a steady test strategy to develop a stable test strategy to ensure the compliance and function of designing a stable test strategy to ensure the compliance and function of designing. In addition to the establishment and testing of these complex assembly, the money invested in electronic parts may be very high -when a unit can reach $ 25,000 when the final test is at the final test. Because of this high cost, the problem of finding and repairing assembly is more important than its past and even more important steps. Today, the more complicated assembly is about 18 square inch inch, 18 floors; there are more than 2,900 components on the top and bottom; it contains 6,000 circuit nodes; more than 20,000 welding points need to be tested. In Langxun Accelerated Manufacturing Factory (N. Andover, MA), manufacturing and testing art -level PCBAs and complete transmission systems. The assembly of more than 5,000 nodes is a concern for us because they are close to

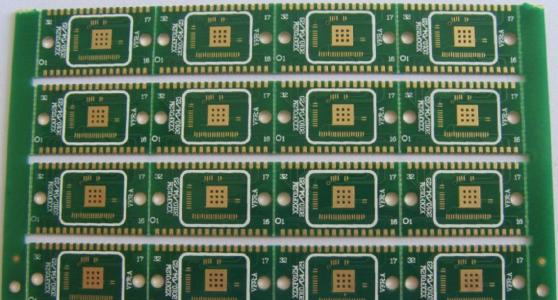

The first PCB uses a hole technology, inserts the hole on one side of the circuit board through the lead, and welded the circuit component to the bronze traces on the other side. The board can be single -sided, with an unpopular component side, or a more compact double panel, welded with components on both sides. By bending 90 degrees in the same direction in the same direction, inserting parts into the circuit board (usually a curved lead on the back of the circuit board), can be installed horizontally with two axial leads (such as resistors, capacitors, and diode). Essence Provide boards in the opposite direction to improve the mechanical strength of parts), welded the lead, and trim the end. The lead can be welded manually or welded with a peak welding machine. Tongkou manufacturing increases the cost of the circuit board by requiring accurate drilling, and limits the available wiring area of the signal wiring on the front of the top layer on the top layer of the top layer of th

There are wiring on both sides of Double-Sided Boards. However, to use the wires on both sides, there must be an appropriate circuit connection on both sides. The "bridge" between this circuit is called a guide hole (VIA). The guide hole is a small hole full of metal on PCB, which can be connected to the wires on both sides. Because the area of the double panel is doubled than the single -panel, and because the wiring can be intertwined with each other (it can be around the other side), it is more suitable for more complicated circuits than a single panel. Strictly speaking, double panels are a very important PCB board in the circuit board. His use is very large. Is it easy to watch the PCB board? Make it, the double panel is the extension of one -piece one -piece, which means that the lines of the single -to -surface are not enough to turn to the opposite side. There is also an important feature of the double panel. There is a guide hole. To put it simply, it is double -sided, and

Appointment Experience