+86 755 2794 4155

+86 755 2794 4155  sales@knownpcb.com

sales@knownpcb.com

-

Shenzhen KNOWNPCB Technology Co., Ltd.

+86 755 2794 4155

+86 755 2794 4155  sales@knownpcb.com

sales@knownpcb.com

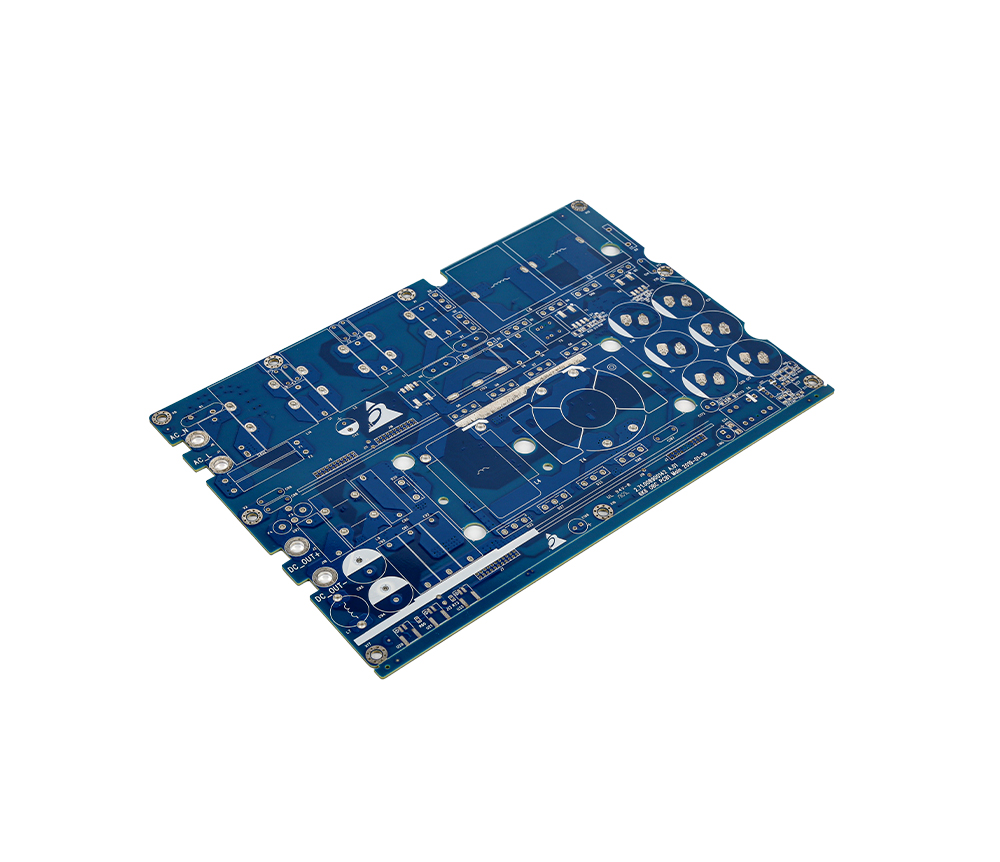

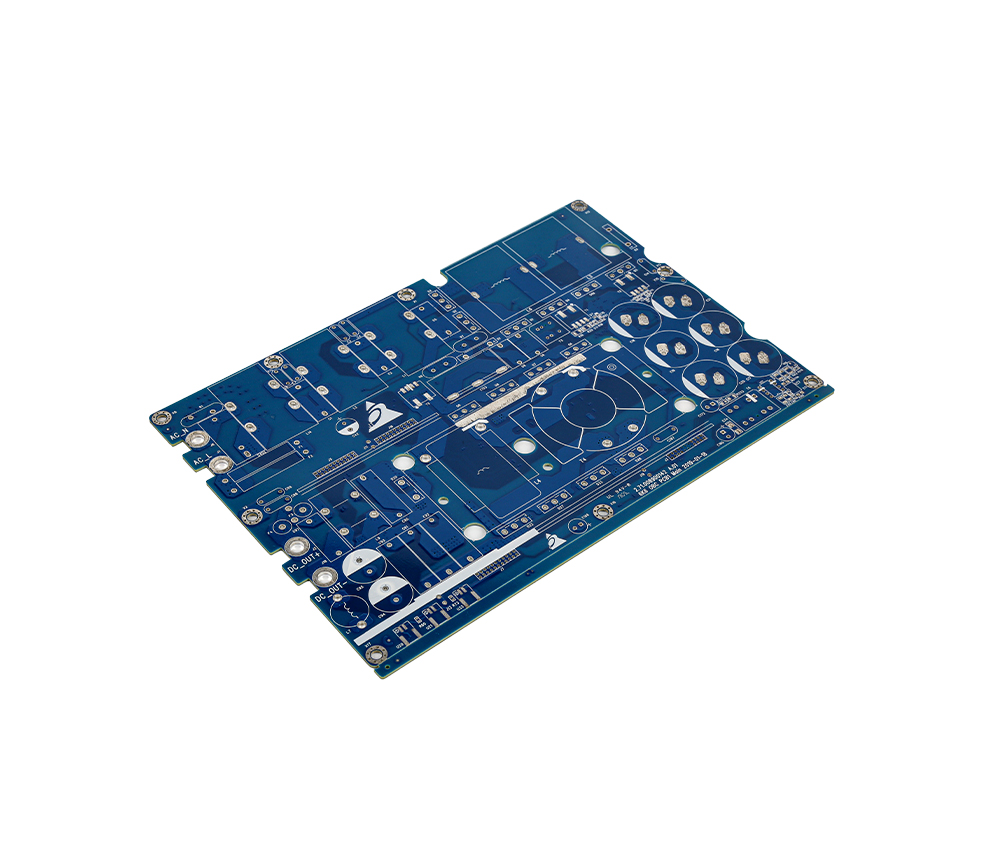

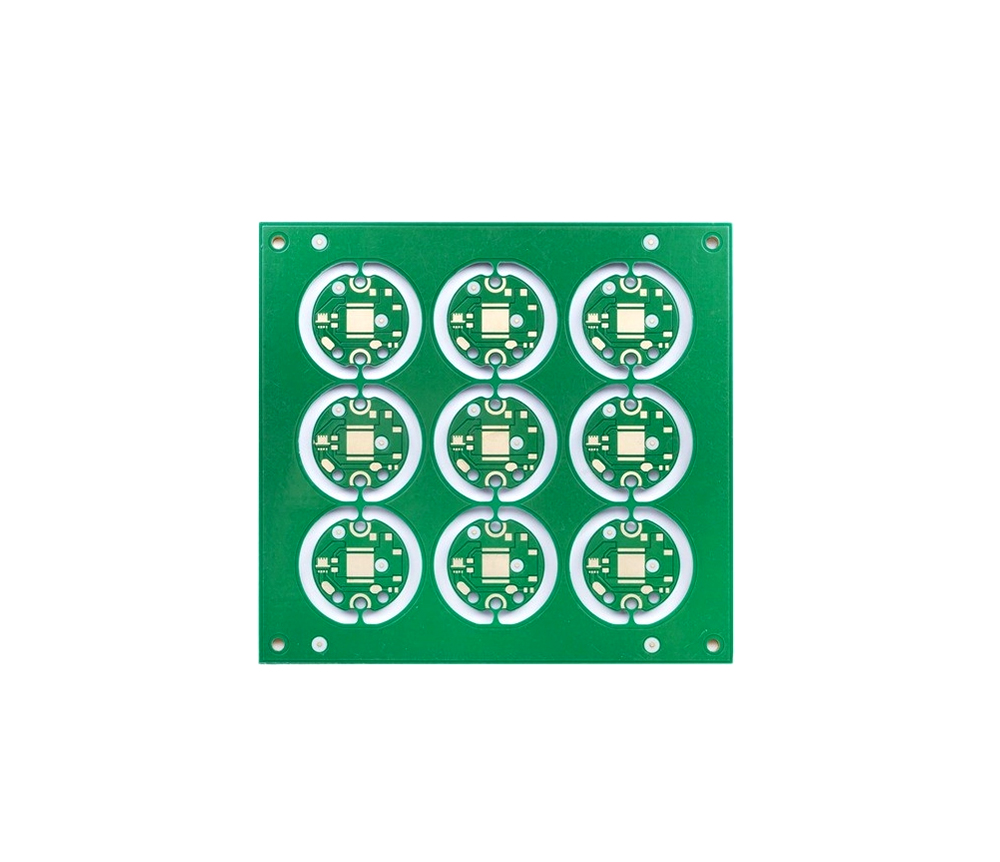

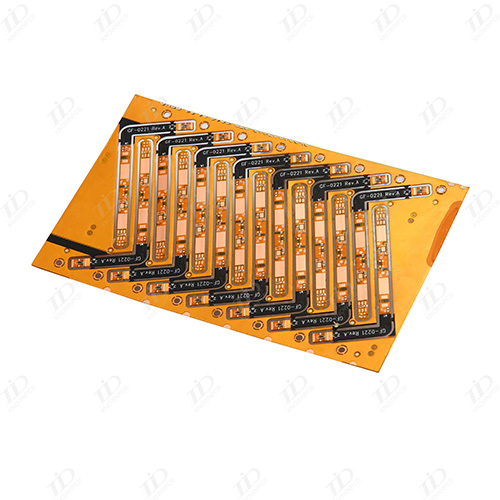

Have you noticed that now more and more of our lighting is using led lighting.What is LED? Compared to the traditional light bulbs, LEDs have lower power consumption, longer lifetime and higher energy efficiency. In the PCB industry,when we say LED PCB, it refers to the pcb used for LED lighting, if you are looking for a suitable LED PCB for your lighting system, this article may bring you something. WHAT ARE LEDS COMPOSED OF?LED is an initial light-emitting diode that produces light when an electric current passes through. LEDs typically have negative and positive electrodes, which generate light in the visible light region.The LEDS are glued to the PCB by soldering process and have electrical connections for lighting.Since light-emitting diodes dissipate a lot of heat when they are in use, when you are designing LED, the metal core is usually the best choice for LED PCB, it is because that it dissipates heat more faster. Among them, the metal material aluminum is the most widely used

1. If it is artificial welding, develop good habits. First of all, check the PCB board again before welding, and check whether the key circuits (especially the power supply and land) are used in a multimeter. Test whether the power and land are short -circuited with a multimeter; in addition, do not shake the soldering iron during welding. If you throw the welding to the welding of the chip (especially the table sticker), it is not easy to find it. 2. Open the PCB diagram on the computer, light up the short -circuited network, and see where the closest to see is the most easily connected to one. Pay special attention to the short circuit inside the IC. 3. Find a short circuit. Take a plate to cut the wire (especially suitable for single/double -layer boards), and after cutting the line, each part of the function block is powered on, and part of it is partially excluded. 4. Use short -circuit positioning analyzers, such as: Singapore Proteq CB2000 short -circuit tracking instrume

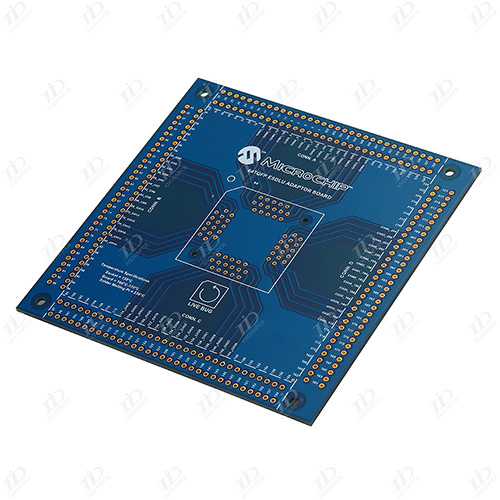

The circuit board includes many types of working levels, such as the signal layer, protective layer, silk printing layer, inner layer, etc. The role of various levels is briefly introduced as follows: ⑴ Signal layer: Mainly used to place components or wiring. Protel DXP usually contains 30 middle layers, namely Mid Layer1 ~ Mid Layer30. The middle layer is used to arrange signal lines, and the top and bottom layers are used to place meta components or copper. Protective layer: It is mainly used to ensure that the tinnic is not required on the circuit board, and it is not plated, thereby ensuring the reliability of the circuit board. Among them, Top Paste and Bottom Paste are top -level welded layers and underlying welded layers; Top Solder and Bottom Solder are the protective layers and underlying tiny paste protective layers, respectively. (3) Silk printing layer: It is mainly used to print the flowing water number, production number, and company name of the component on the ci

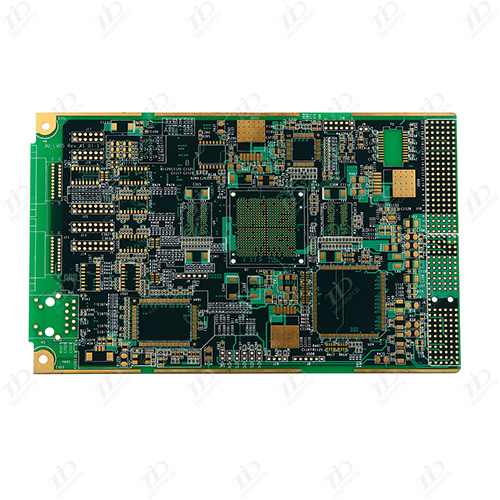

The number of layers of the board represents several independent wiring layers. Usually the number of layers is even, and contains two layers on the outermost side. Most of the motherboards are 4 to 8 layers, but it can be technically able to achieve nearly 100 layers of PCB boards. Most of the large supercomputers use quite many layers of motherboards, but because these computers can already replace the cluster of many ordinary computers, the super -multi -layer board has gradually been gradually not used. Because each layer in PCB is closely combined, it is generally not easy to see the actual number, but if you carefully observe the motherboard, you may see. The automatic detection technology of the circuit board is applied with the introduction of surface installation technology, and the packaging density of the circuit board is rapidly increased. Therefore, the automatic detection of the circuit board is not only basic, but also economically even for the low -density and gene

The copper foil substrate is cut into size suitable for processing production. Before the substrate is compressed, it is usually necessary to use brushing, micro -erosion and other methods to properly crudely treat the plate surface of copper foil, and then attach the dry membrane light to the top with appropriate temperature and pressure. Send the substrate with the dry membrane light resistance into the ultraviolet exposure machine to expose. After the light resistance is illuminated by ultraviolet rays in the negative light, it will generate a polymerization reaction (the dry membranes of the area will be in the subsequent development and the copper steps of copper will be will be will be will be will be being being exposed. Keep it as a etching resistant), and move the line image on the negatives to the obstruction of the dry membrane of the plate. After tearing off the protective film on the membrane surface, first use sodium carbonate aquatic solution to remove the zone that

One -panel Single-SIDED BOARDS We just mentioned it, so we call this PCB called Single-SIDED. Because there are many strict limitations on the design lines on the design line (because there is only one side, the path that cannot be handed in the wiring between the wiring is necessary), so only this type of board is used in the early circuit. Double panel Double-size boards There are wiring on both sides of this circuit board. However, to use the wires on both sides, there must be an appropriate circuit connection on both sides. The "bridge" between this circuit is called a guide hole (VIA). The guide hole is a small hole full of metal on PCB, which can be connected to the wires on both sides. Because the area of the double panel is doubled than the single -panel, and because the wiring can be intertwined with each other (it can be around the other side), it is more suitable for more complicated circuits than a single panel. Multi -layer [Multi -layer board] When more complex

As an important part of the PCB design, whether it is domestic PCB design software or some protes abroad, PowerPCB provides intelligence, so how can I apply the copper. Swinging brings benefits. The so -called copper covering is to use the idle space on the PCB as the benchmark surface, and then fill it with solid copper. These copper areas are also called irrigated copper. The significance of copper covering is to reduce the impedance of the ground and improve the anti -interference ability; reduce the pressure drop and improve the efficiency of the power; connect with the ground line, and can also reduce the area of the circuit. In order to allow PCB to welded as much as possible, most PCB manufacturers also require PCB designers to fill the copper skin or grid -like ground line in the empty area of PCB. If the copper covering is not handled properly, it will be worthless. Is the copper covering "benefits greater than the disadvantages" or "disadvantage is greater than benefits

1. If there are many land in PCB, there are SGND, Agnd, GND, etc., and according to the different positions of the PCB board surface, you should use the main "ground" as the benchmark reference to cover the copper. Digital ground and simulation are separated to cover copper. Before the copper is covered, the corresponding power connection is first thicken: 5.0V, 3.3V, etc. In this way structure. 2. For single -point connections in different places, the method is to connect through 0 Euro resistance, magnetic beads or inductance; 3. Copper crop near the crystal, the crystal in the circuit is a high -frequency transmission source, the method is to surround the crystal correction copper, and then the crystal shell is grounded separately. 4. If the island (dead area) problem, if it feels very large, it will not take much money to define a place to add the holes. 5. When starting the wiring, deal with the ground wires, and you should take the ground wire well when you walk. You cann

(1) The ERC reports have no access signal: a. Define the I/O attributes for the pipeline when creating packaging; b. Modify the inconsistent GRID attributes when creating an element or placing an element. c. When creating components, the direction of PIN is reverse, and it must be unconnected in the PIN NAME end. d. The more common reasons are that there are no engineering documents. This is a mistake that beginners make. (2) Components run outside the drawing industry: No components are created in the component library diagram table paper center. (3) The created engineering file network table can only be partially transferred to the PCB: when generating Netlist, no selection is Global. (4) When using multiple parts created by yourself, do not use Annotate.

(1) Report node when the network is loaded, not found a. The components in the schematic diagram use the package that is not available in the PCB library; b. The components in the schematic diagram use the name of the name in the PCB library inconsistently packaging; c. The components in the schematic diagram use the PIN Number in the PCB library inconsistent packaging. For example, the triode: Pin Number in SCH is E, B, C, and PCB is 1, 2, 3. (2) You can never print it on a page when printing a. No at the original point when creating the PCB library; b. Move and rotate components multiple times, and there are hidden characters outside the PCB board. Select all hidden characters, reduce PCB, and then move the character to the boundary. (3) The DRC report network is divided into several parts: It means that this network is not connected, read the report file, and select the Connected Copper to find. If it is more complicated, try not to use automatic wiring.

1. Engineering Design The arrangement of interlayer semi cured sheets should correspond; Multi layer core boards and semi cured sheets should use the same supplier's products; The outer C/S surface graphics area should be as close as possible, and independent grids can be used; 2. Drying board before cutting Generally, at 150 degrees Celsius for 6-10 hours, the moisture inside the board is removed, further allowing the resin to cure completely and eliminating stress inside the board; Drying the board before opening, both the inner layer and both sides are required! 3. Attention should be paid to the warp and weft directions of the cured sheet before laminating the multi-layer board The shrinkage ratio in the warp and weft directions is different, so pay attention to distinguishing the warp and weft directions before cutting and stacking the semi cured sheet; When cutting the core board, attention should also be paid to the warp and weft directions; The general direction of the

Poor solderability of circuit board holes will result in solder defects, affecting the parameters of components in the circuit, leading to unstable conduction of multi-layer board components and inner wires, and causing the entire circuit function to fail. The so-called weldability refers to the property of the metal surface being wetted by molten solder, which means that the solder forms a relatively uniform and continuous smooth adhesive film on the metal surface. The main factors affecting the solderability of printed circuit boards are: (1) the composition of the solder and the properties of the soldered material. Solder is an important part of the welding chemical treatment process. It consists of chemical materials containing flux. The commonly used low melting point eutectic metal is Sn Pb or Sn Pb Ag. The impurity content should be controlled in proportion to prevent the oxide produced by impurities from being dissolved by flux. The function of solder is to help wet the sur

In terms of layout, when the circuit board size is too large, although welding is easier to control, the printed lines are longer, the impedance increases, the noise resistance decreases, and the cost increases; Over time, the heat dissipation decreases, making it difficult to control welding and prone to interference between adjacent lines, such as electromagnetic interference from circuit boards. Therefore, it is necessary to optimize PCB board design: (1) shorten the wiring between high-frequency components and reduce EMI interference. (2) Components with large weight (such as exceeding 20g) should be fixed with brackets and then welded. (3) Heating elements should consider heat dissipation to prevent significant surface damage Δ If defects occur and rework occurs, the thermistor should be kept away from the heat source. (4) The arrangement of components should be as parallel as possible, which is not only aesthetically pleasing but also easy to weld, making it suitable for mass

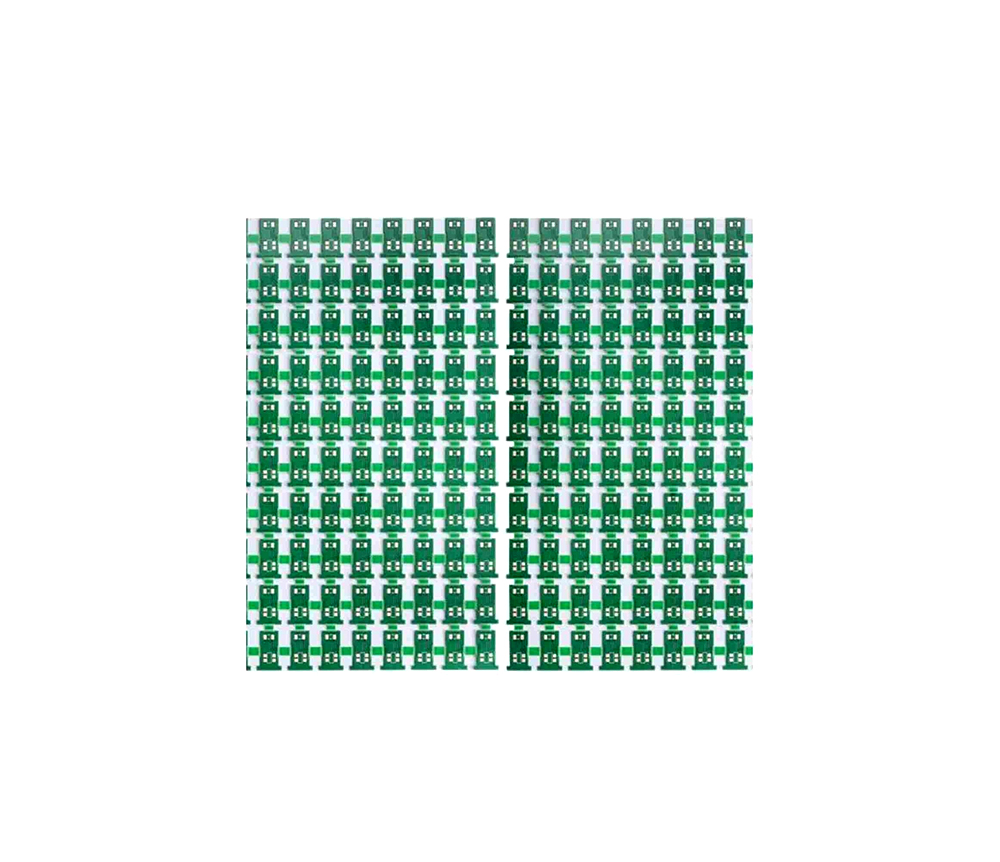

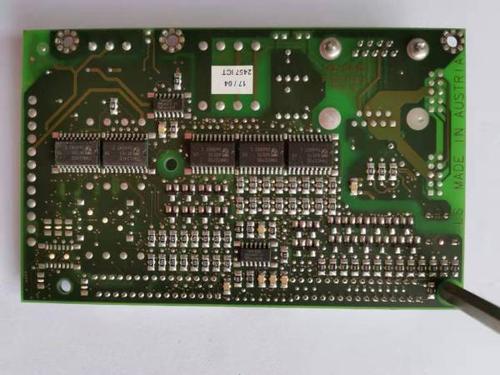

Firstly, during the production and processing of PCB boards, there will be a certain proportion of defective products. At this point, we need to use mechanical equipment to inspect and screen out unqualified defective products. Therefore, we need to conduct electrical testing. So, what is the difference between testing and flying needle testing? The testing is divided into test fixture testing and flying needle testing, In terms of speed, the test frame test will be faster, and the flying needle test will be slower In terms of cost, the cost of testing racks is higher As for which testing method to choose, we need to choose based on the number of PCBs. For those with a large number, choose a testing rack, and for those with a small number, choose flying pins Based on cost, time efficiency, and comprehensive evaluation and selection

In the automotive market, new energy vehicles have become a rising star, and every car company has launched their own new energy vehicles, which is enough to show that new energy vehicles are the trend and will inevitably enter thousands of households. However, every development process is always full of uncertainty, and there are always new problems waiting to be solved. Whether the subsidy policy for new energy is reasonable, how new energy can smoothly enter the market, and how to avoid new energy safety accidents... In the process of exploring and advancing, new energy vehicles have faced a series of problems thrown by the market. Now, the editor of the circuit board has learned that with the gradual fading of new energy subsidies, the influx of foreign enterprises, and the arrival of the marketization stage of new forces in car manufacturing, the market has raised a new question for new energy vehicle companies - can they make money by selling new energy vehicles? The Double

There are many types of circuit boards with different names, which can be named based on materials, layers, inherent characteristics, and other aspects. For example, there are: single panel, double-sided board, multi-layer board, HDI, fast board, FR4 circuit board, ceramic circuit board, alumina ceramic circuit board, aluminum nitride ceramic circuit board, circuit board, PCB board, aluminum substrate, high-frequency board, thick copper board, impedance board, PCB, ultra-thin circuit board, ultra-thin circuit board, Printing (copper etching technology) circuit boards, etc. Circuit boards are miniaturized and intuitive, playing an important role in the mass production of fixed circuits and optimizing the layout of electrical appliances Printed circuit boards (PCBs) are essential accessories in modern electronic equipment. All electronic devices, whether they are large machinery, personal computers, communication base stations, mobile phones, household appliances, or electronic toys

The video measurement system is suitable for measuring prismatic workpieces with intersecting planes. When planes intersect, edges appear, and videos can easily measure edges. Orthopaedic transplantation components are usually composed of continuous and regular curves (artificial hip joint fittings) or complex contour surfaces (artificial knee joint fittings), whose shape is just like the contour of human organ. These surfaces have few or no flat or intersecting edges. Although video sensors are good at measuring edges and surface points, using a large number of data points to obtain data on even linear cross-sections of contour surfaces is very laborious and impractical. Trigger probes also have the same limitations, as they need to approach each point and return to the plateau after triggering - although feasible, they are also not suitable for measuring large quantities of products. The best method to determine whether the bionic curve contour of artificial knee joint meets th

In addition to the wiring on the substrate, the metal coating is the place where the substrate line and electronic component are welded. In addition, different metals also have different prices, and different ones will directly affect the cost of production. Different metals also have different weldability and contact, as well as different resistance values, which will directly affect the effectiveness of the component. Common metal coatings include: copper tin The thickness is usually 5 to 15 μm Lead tin alloy (or tin copper alloy) That is welded, the thickness is usually 5 to 25 μm, and the tin content is about 63% gold Generally only plated in the interface silver Generally, it is only placed in the interface, or the alloy of silver with the whole

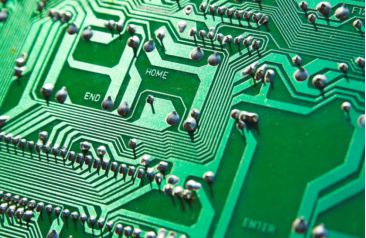

Because it is made of electronic printing technology, it is called a "printing" circuit board. Before the emergence of the printed circuit board, the interconnection between electronic components rely on the wires to directly connect to form a complete line. Circuit bread boards exist only as effective experimental tools, and the printing circuit board has become an absolute dominance in the electronics industry. At the beginning of the 20th century, in order to simplify the production of electronic machines, reduce the wiring between electronic parts, and reduce the advantages of production costs, they began to study the method of replacing the wiring by printing. In the past thirty years, engineers have continued to propose a metal conductor on the insulating substrate as a wiring. The most successful is that in 1925, Charles Ducas in the United States printed out line patterns on the insulated substrate, and successfully established a conductor to wiring in an electroplating.

The substrate is generally classified as the insulation part of the substrate. The common raw materials are electric wood plates, glass fiber plates, and various types of plastic plates. The PCB manufacturers generally use an insulating part of glass fiber, non -fabrics, and resin, and then suppressed in epoxy resin and copper foil as "Prepreg". The common substrates and main ingredients are: FR-1-phenolic cotton paper, this substrate is commonly referred to as electric wooden boards (higher economy than FR-2) FR-2 ─ Phenolin cotton paper, FR-3-Cotton Paper, epoxy resin FR-4-Woven Glass, epoxy resin FR-5-glass cloth, epoxy resin FR-6-f f f, polyester G-10-glass cloth, epoxy resin CEM-1-cotton paper, epoxy resin (flame retardant) CEM-2-cotton paper, epoxy resin (non-flame retardant) CEM-3-glass cloth, epoxy resin CEM-4-glass cloth, epoxy resin CEM-5-glass cloth, polyester Ain -aluminum nitride SIC -silicon carbide

It is important to develop a steady test strategy to develop a stable test strategy to ensure the compliance and function of designing a stable test strategy to ensure the compliance and function of designing. In addition to the establishment and testing of these complex assembly, the money invested in electronic parts may be very high -when a unit can reach $ 25,000 when the final test is at the final test. Because of this high cost, the problem of finding and repairing assembly is more important than its past and even more important steps. Today, the more complicated assembly is about 18 square inch inch, 18 floors; there are more than 2,900 components on the top and bottom; it contains 6,000 circuit nodes; more than 20,000 welding points need to be tested. In Langxun Accelerated Manufacturing Factory (N. Andover, MA), manufacturing and testing art -level PCBAs and complete transmission systems. The assembly of more than 5,000 nodes is a concern for us because they are close to

Inquiry Now