+86 755 2794 4155

+86 755 2794 4155  sales@knownpcb.com

sales@knownpcb.com

-

Shenzhen KNOWNPCB Technology Co., Ltd.

+86 755 2794 4155

+86 755 2794 4155  sales@knownpcb.com

sales@knownpcb.com

Have you noticed that now more and more of our lighting is using led lighting.What is LED? Compared to the traditional light bulbs, LEDs have lower power consumption, longer lifetime and higher energy efficiency. In the PCB industry,when we say LED PCB, it refers to the pcb used for LED lighting, if you are looking for a suitable LED PCB for your lighting system, this article may bring you something. WHAT ARE LEDS COMPOSED OF?LED is an initial light-emitting diode that produces light when an electric current passes through. LEDs typically have negative and positive electrodes, which generate light in the visible light region.The LEDS are glued to the PCB by soldering process and have electrical connections for lighting.Since light-emitting diodes dissipate a lot of heat when they are in use, when you are designing LED, the metal core is usually the best choice for LED PCB, it is because that it dissipates heat more faster. Among them, the metal material aluminum is the most widely used

Because there are dozens of types of CAD software popular on the market, the management of CAD processes must be first started from the organization, and good organizations will achieve more effort. Since the GERBER data format has become the standard for the optical painting industry, GERBER data should be processed in the entire optical painting process. If CAD data is used as an object, the following problems will bring. (1) There are too many types of CAD software. If all kinds of process requirements must be completed in CAD software, each operator is required to be proficient in the operation of each CAD software. This will require a long training period to make the operator a skilled worker and meet the actual production requirements. This is not cost -effective from time and economic perspective. (2) Due to the large number of process requirements, some requirements cannot be achieved for certain CAD software. Because CAD software is used for design, it is impossible to m

Computer -assisted manufacturing (CAM) is processed according to the final process. The requirements of the process mentioned earlier must make necessary preparations before light painting. For example, the problems of mirroring, welding expansion, craft lines, craft frames, line width adjustment, central holes, and appearance lines must be completed in the CAM process. In particular, it is important to note that there must be a corresponding process in the intermediate distance between the user file and must be processed accordingly. Because the process and technical level of each factory are different, to meet the ultimate requirements of the user, the necessary adjustments must be made in the production process to meet the requirements of the user's relevant accuracy. Therefore, CAM processing is an indispensable process in the manufacturing of modern printing circuits. ① Fix the size of the pad, combat D code. ② Correct the width of the line, combat D code. ③ Check the mini

1. Several temperature parameters in temperature and layer pressure are more important. That is, the melting temperature of the resin, the curing temperature of the resin, the temperature of the heat disk setting, the actual temperature of the material, and the speed of the heating. The resin starts to melt when the temperature of the melting temperature rises to 70 ° C. It is precisely because of the further increase of temperature that resin is further melted and flows. During the period of temperature of 70-140 ° C, resin is easy to fluid. It is precisely because of the popularity of the resin that it ensures that the resin fills and humidity. As the temperature gradually increases, the liquidity of the resin has gone through a small change from small to large, then small, and finally when the temperature reaches 160-170 ° C, the fluidity of the resin is 0. At this time, the temperature is called the curing temperature. In order to enable the resin to fill the glue and humidity

When the multi -layer layer is pressed, the inner core plate is required. The treatment process of the inner plate has black oxidation treatment and brown treatment process. The oxidation treatment process is to form a black oxide film on the inner copper foil, and the thickness of the black oxide film is 0.25-4). 50mg / cm2. The brown treatment process (horizontal brownization) forms a layer of organic membrane on the inner copper foil. The inner plate processing process is: 1. Increase the surface of the inner copper foil and resin to enhance the combination between the two. 2. Increase the effective and moistness of copper foil when the melting resin flows, so that the flowing resin has sufficient ability to extend the oxidation film, and show a strong grip after solidification. 3. Stop the impact of the decomposition of anemia in the liquid resin at high temperature at high temperature. 4. Make multi -layer boards improve acid resistance and prevent pink circle in the wet p

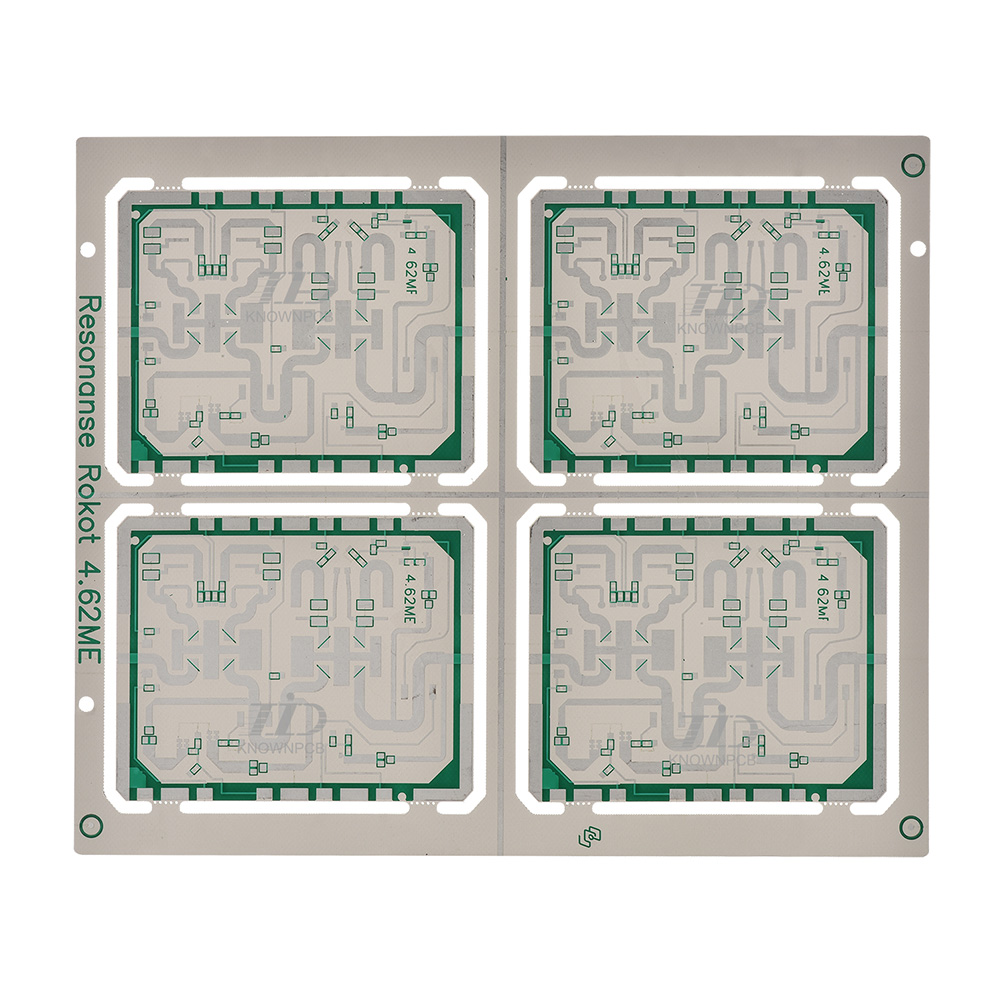

PCB line board price analysis PCB price consists of the following factors: 1. The materials used in PCB line boards are different Taking ordinary double panels as an example, plate materials generally include FR-4, CEM-3, etc., the thickness of the board ranges from 0.6mm to 3.0mm, and the copper thickness is different from ½OZ to 3 OZ. In terms of welding ink, there is a certain price difference in ordinary thermal solid oil and light sensitive green oil. 2. PCB uses different production processes Different production processes will cause different costs. For example, the gold -plated board and tin spray plate, making the gong (milling) board and beer (punch) board, the use of silk print lines and dry membrane lines will form different costs. Third, the PCB line board itself is difficult to be different Even if the materials are the same and the craftsmanship, the difficulty of PCB itself will cause different costs. For example, there are 1,000 holes on both line boards, and

PCB copper -covering board grade division 1. FR-4 A1 Copper Copy Copper Board This class is mainly used in electronic products such as military industry, communication, computers, digital circuits, industrial instruments, automotive circuits and other electronic products. The quality of this series of products has completely reached the world -class level, and it is the company with the highest grade and best performance. 2. FR-4 A2 Copper Cover Copper Plate. This level is mainly used for ordinary computers, instrumentations, senior home appliances and general electronic products. This series of copper -covering plates are widely used, and various performance indicators can meet the needs of general industrial electronic products. There is a good price performance ratio. Can enable customers to effectively improve price competitiveness. 3. FR-4 A3 Copper Crystal Copper Copper is a FR-4 product developed and produced for the company's home appliance industry, computer peripheral pr

PCB mechanical network printing common failure and cause countermeasures 1) There is a gap in the mouth of the scraper -grill. 2) The stress of the scraper is too small -increase the scraper pressure. 3) The distance between the network version and the printed board is too large -adjusting the network distance. 4) The raising of the mesh box causes uneven pressure of scraping -to change the net frame, re -stretch the net, and the network version. 5) The printing of the printing is too large -the preparation of the printing and the use of stability after the deployment. 6) The mask of the network version is too thick, through the small printing volume, and the net printing wire is too thin -the net version of the net must control the thickness of the mask (direct method). 7) The speed of the net printing is too fast -properly adjust the speed of the net printing. 8) Select improper printing and the number of silk nets is too high -replacement of the printing, and select the si

PCB osmotic ink 1) The mouth of the scraper becomes round -grinding scraper mouth. 2) The angle of the scraper network is too small -properly adjust the angle of the large scraper net. 3) The viscosity of the printing is too low -the exchanges with a large viscosity. 4) Poor solvents and printed mixing -fully stir up the printing before the net printing. 5) Wipe the network version with the solvent. After the solvent is not completely volatilized, the net prints -after the scrubbing version, the net printing after the solvent is volatilized. 6) The number of silk networks is too low -the Silk net version of the high net is used.

The flying needle tester does not depend on the insert pattern installed on a fixture or bracket. Based on this system, two or more probes are installed on the x-y plane that can be moved freely on the small magnetic head, and the test point is CADI GERBER data is directly controlled. The dual probe can move within the range of 4mil. The probe can move independently and does not really limit their degree of approaching each other. Tester with two back -and -forth arm -shaped objects is based on the measurement of capacitors. Press the circuit board on the insulating layer on a metal plate as another metal board of the capacitor. If there is a short circuit between the lines, the capacitor will be larger than a certain point. If there is-bargaining, the capacitance will become smaller. Test speed is an important criterion for choosing a tester. The needle bed tester can accurately test thousands of test points at one time, and the flying needle tester can only test two or four tes

This method is connected to each detection point on the circuit board from a probe with a spring. The spring makes each probe with 100 -200g pressure to ensure that each detection point is well -touched. Such a probe is called "needle bed" together. Under the control of the detection software, the detection point and the detection signal can be programmed. Figure 14-3 is a typical needle bed tester structure. Detectors can know the information of all test points. In fact, only the probes of test points that need to be tested are installed. Although the needle bed test method may be detected at both sides of the circuit board at the same time. When designing the circuit board, all the detection points should still be on the welding surface of the circuit board. Needle tester equipment is expensive and difficult to repair. The needle selects different arrangements according to its specific application. A basic general raster processor is composed of a drilling board with a pitch of

1. OSP main component concentration: alkyl pyramazole or similar ingredients (imazole) is the main ingredient in OSP medicinal solution. The concentration of the concentration is the root of determining the thickness of the OSP membrane. 2. Organic acid: The addition of organic acid can increase the solubility of alkyl pyramazole in the aqueous solution. Promote the formation of a combination of protective film. However, too much dosage can dissolve the protective membrane deposited on the surface of the copper, so it is crucial to control the added value of organic acid (ie, the pH value). When the pH value is too high, the solubility of the alkyl pyramole is reduced, and the oil -shaped object is precipitated, which is not good for immersion. The pH value control can obtain a complex with a dense, uniform, and thick thickness. When the pH value is too low, the solubility of the linked membrane increases, which can dissolve the complex deposited on the copper without forming a me

Causes of tin beard: 1. The mutual diffusion between the tin and the copper forms metal interoperability, resulting in the rapid growth of the internal pressure stress of the tin layer, resulting in the diffusion of the tin atom along the crystal boundary to form tin beard; 2. The residual stress of the plating layer after electroplating causes the growth of tin beards. solution: 1. Electro -plating fog tin, change the structure of its crystals, and reduce stress; 2. Bake up at 150 for 2 hours. (Experiments have proved that at more than 90, tin beard will stop growing) 3. Add a small amount of organic metal additives for ENTHONE FST ingening process to limit the raw of tin copper metal interoperabilitybecome; 4. Add a layer of blocking layer between tin and copper, such as nickel layer.

Circuit board short circuits are a problem that almost every circuit board manufacturer encounters on a daily basis, and such problems have always troubled production and quality management personnel. The problems caused by it include replenishment due to insufficient shipment quantity, delayed delivery, and customer complaints, which are relatively difficult for industry insiders to solve. We first summarize and classify the main causes of PCB open circuits into the following aspects: Open circuit caused by exposed substrate: 1. There are scratches on the copper clad plate before entering the warehouse; 2. The copper clad plate was scratched during the cutting process; 3. The copper clad plate was scratched by the drilling nozzle during drilling; 4. The copper clad plate was scratched during transportation; 5. The surface copper foil was damaged due to improper operation during the stacking of boards after copper deposition; 6. The copper foil on the surface of the product

1. Before entering the warehouse, IQC must conduct spot checks on the copper clad board to check if there are any scratches or exposed substrate on the board surface. If there are any, the supplier should be contacted in a timely manner and appropriate measures should be taken based on the actual situation. 2. The copper clad plate was scratched during the cutting process, mainly due to the presence of hard and sharp objects on the cutting machine table. During the cutting process, the copper foil was scratched and the substrate was exposed due to friction between the copper clad plate and the sharp objects. Therefore, before cutting, the table must be carefully cleaned to ensure that the table is smooth and free of hard and sharp objects. 3. The copper clad plate was scratched by the drill bit during drilling, mainly due to the wear of the spindle clamp or the uncleaned debris inside the clamp. The PCB sampling grab drill bit cannot grip firmly, and the drill bit does not reach

The advantages and disadvantages are obvious: Advantages: Low cost, flat surface, good weldability (without oxidation). Disadvantages: It is easily affected by acid and humidity and cannot be stored for a long time. It needs to be used up within 2 hours after opening the seal, as copper is prone to oxidation when exposed to air; It cannot be used on double-sided boards because the second side has already oxidized after the first reflow soldering. If there is a Test point, solder paste must be printed to prevent oxidation, otherwise it will not be able to contact the probe well later. Pure copper is easily oxidized when exposed to air, and the outer layer must have the above protective layer. And some people believe that the golden color is copper, which is a wrong idea because it is the protective layer on top of copper. So it is necessary to extensively gild the circuit board, which is the gold deposition process that I have previously introduced to everyone.

Gold is the true gold. Even if only a very thin layer is plated, it already accounts for nearly 10% of the cost of the circuit board. There are many merchants in Shenzhen who specialize in purchasing waste circuit boards and use certain means to wash out gold, which is a good income. The use of gold as a coating is for the convenience of welding and for corrosion prevention. Even the gold fingers of memory modules that have been in use for several years still flicker like before. If copper, aluminum, and iron were used in the past, they would now rust into a pile of waste. The gold plating layer is widely used in the solder pads, gold fingers, connector shrapnel and other positions of circuit boards. If you find that the circuit board is actually silver, it goes without saying. If you directly call the consumer rights hotline, it must be that the manufacturer cut corners, did not use the materials properly, and used other metals to deceive customers. The motherboards of the most

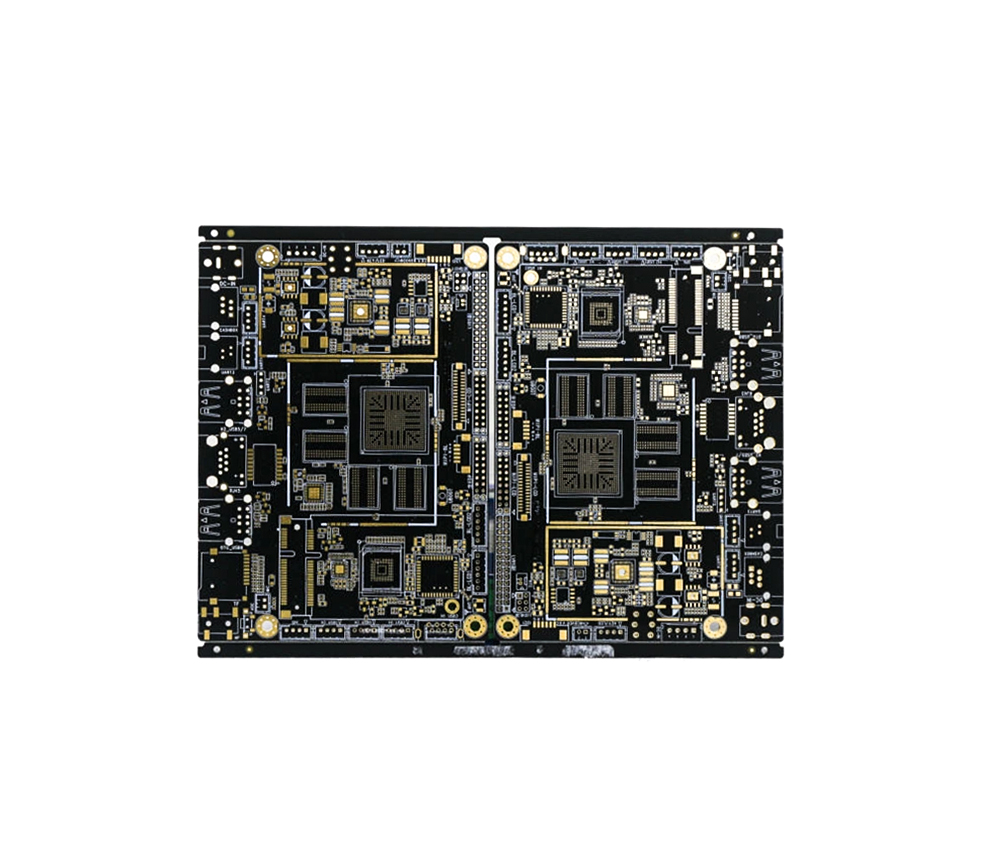

As a manufacturer, you know that the quality of products depends on the components you use. When it comes to printed circuit boards (PCBs), the color of the board may not seem important,but have you ever wondered if the color of a PCB board can determine its quality? The raw material of pcb is everywhere in our daily life, that is, glass fiber and resin, glass fiber and resin combined, hardened, became a kind of heat insulation, insulation, and not easy to bend the board, this is the pcb substrate, of course, light by the combination of glass fiber and resin pcb substrate can not be transmitted to the signal, so on the pcb substrate, The manufacturer will cover the surface with a layer of copper, so the pcb substrate can also be called a copper-coated substrate The color of a PCB board has no direct correlation with its performance. The performance of a PCB board is determined by the materials used, wiring design, and number of layers. However, during the PCB washing process, bla

PCB buyers have always been confused about the color of PCB. I don't know what color PCB board is high -quality. Let's explain today what the PCB color affects its performance. First of all, PCB, as a printing line board, mainly provides mutual connection between electronic components. Color and performance are not directly related, and the differences in pigments will not affect electrical. Whether the performance of the PCB board is determined by factors such as the materials used (high Q value), wiring design, and several plates. However, in the process of washing PCB, black is the most likely to cause color difference. If the raw materials and manufacturing processes used by the PCB factory are slightly deviated, the PCB adverse rate will increase due to color difference. This directly leads to an increase in production costs. In fact, the raw materials of PCB are everywhere in our daily life, that is glass fiber and resin. The combination of glass fiber and resin and hardeni

1. Excessive etching of copper foil. The electrolytic copper foil used in the market is generally single -sided galvanized (commonly known as gray foil) and single -sided copper plating (commonly known as red foil). Common copper shampoo is generally galvanized copper above 70um or more Foil, red foil and gray foil below 18um basically have not seen batch -shaped copper. When the customer line design is better than the etching line, if the copper foil specifications change and the etch parameters have not changed, causing the copper foil to stay in the etching solution for too long. Because zinc was originally a lively metal, when the copper line on the PCB was soaked in the etching solution for a long time, it would cause excessive line erosion of the line, resulting in some thin lines against the zinc layer. That is, the copper thread falls off. Another situation is that there is no problem with the PCB etching parameters, but after etching, water washing, and poor drying, result

1. It is mentioned that ordinary electrolytic copper foil is a product made by galvan foil or copper plating. The peeling strength is not enough. When the bad foil suppression plate is made into a PCB plug -in in the electronics factory, the copper wire will fall off by the impact of external forces. This type of copper -throwing a copper thread to see the copper foil surface (that is, the contact surface of the substrate). 2. Poor adaptability of copper foil and resin: some special performance layer -made plates used now, such as HTG plates, because the resin system is different, the solid agent is generally PN resin, the resin molecular chain structure is simple, when the solidification is solidified, and when it is solidified The degree of cross -linking is low, and the copper foil with special peak values is necessary to match it. When the production layer is used, the copper foil is not matched with the resin system, resulting in insufficient peeling strength of the plate cov

Inquiry Now