+86 755 2794 4155

+86 755 2794 4155  sales@knownpcb.com

sales@knownpcb.com

-

Shenzhen KNOWNPCB Technology Co., Ltd.

+86 755 2794 4155

+86 755 2794 4155  sales@knownpcb.com

sales@knownpcb.com

Have you noticed that now more and more of our lighting is using led lighting.What is LED? Compared to the traditional light bulbs, LEDs have lower power consumption, longer lifetime and higher energy efficiency. In the PCB industry,when we say LED PCB, it refers to the pcb used for LED lighting, if you are looking for a suitable LED PCB for your lighting system, this article may bring you something. WHAT ARE LEDS COMPOSED OF?LED is an initial light-emitting diode that produces light when an electric current passes through. LEDs typically have negative and positive electrodes, which generate light in the visible light region.The LEDS are glued to the PCB by soldering process and have electrical connections for lighting.Since light-emitting diodes dissipate a lot of heat when they are in use, when you are designing LED, the metal core is usually the best choice for LED PCB, it is because that it dissipates heat more faster. Among them, the metal material aluminum is the most widely used

Plastic circuit boards are another type of thermoplastic engineering plastic circuit board compared to the traditional thermosetting epoxy resin fiberglass that is widely used in the electronics industry. Traditional printed circuit boards are made by die-casting thermosetting resin and glass fiber into a substrate, and then bonding conductive copper foil onto the substrate. It is called printed circuit copper clad plate. Copper clad boards are made into printed circuit boards through processes such as exposure and etching. This process has armed the electronics industry to this day. However, the process of removing copper foil involves environmental issues, and approval of circuit board licenses is strictly prohibited in many regions. Printed circuit boards are a planar structure, although flexible circuit boards can be formed on curved surfaces as a branch, they are not rigid curved three-dimensional structures. Some emerging applications, such as robots, 3D lighting fixtures, a

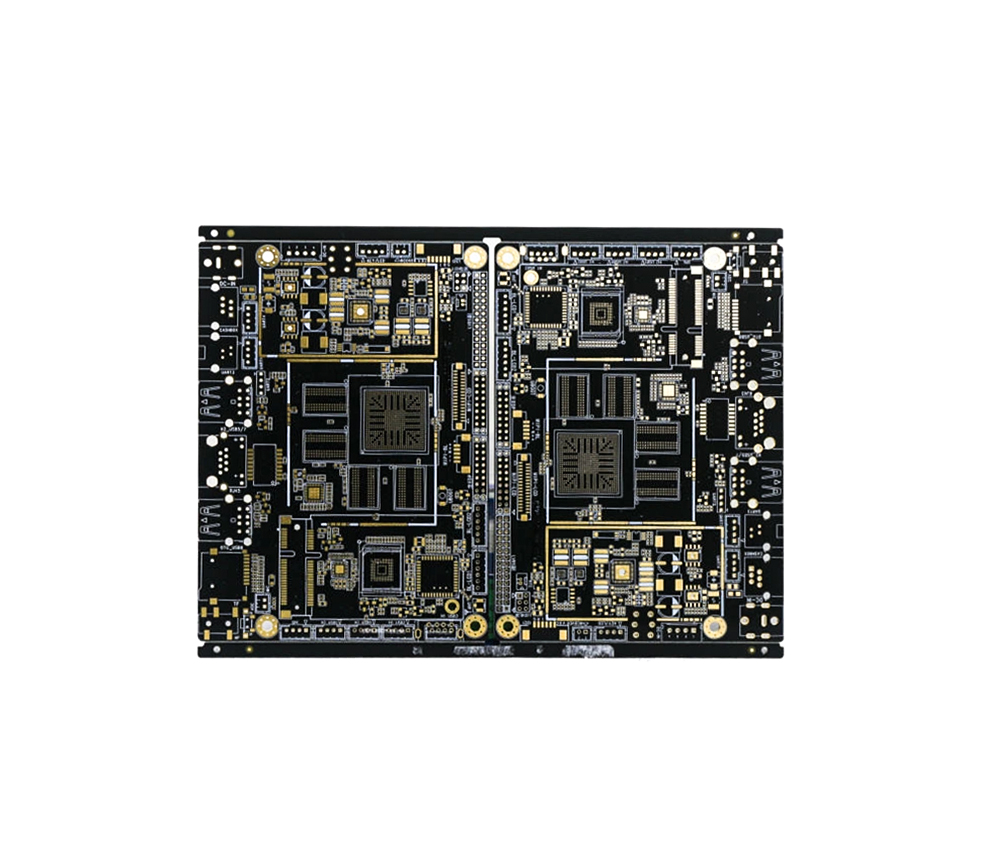

The memory packaged with BGA technology can increase the memory capacity by two to three times without changing its volume. Compared with TSOP, BGA has smaller volume, better heat dissipation performance, and electrical performance. BGA packaging technology has greatly improved the storage capacity per square inch. Memory products using BGA packaging technology have a volume of only one-third that of TSOP packaging at the same capacity; In addition, compared to traditional TSOP packaging methods, BGA packaging has a faster and more effective heat dissipation path. The I/O terminals of BGA packaging are distributed in an array of circular or columnar solder joints below the packaging. The advantage of BGA technology is that although the number of I/O pins increases, the pin spacing does not decrease but increases, thereby improving the assembly yield; Although its power consumption increases, BGA can be soldered using a controllable collapse chip method, which can improve its electro

As soon as BGA emerged, it became the best choice for high-density, high-performance, multifunctional, and high I/O pin packaging of VLSI chips such as CPUs and north-south bridges. Its characteristics include: Although the number of I/O pins has increased, the pin spacing is much greater than that of QFP, thereby improving the assembly yield; Although its power consumption increases, BGA can be soldered using the controllable collapse chip method, abbreviated as C4 soldering, which can improve its electric heating performance; 3. The thickness is reduced by more than 1/2 compared to QFP, and the weight is reduced by more than 3/4; 4. The parasitic parameters are reduced, the signal transmission delay is small, and the usage frequency is greatly increased; 5. Assembly can be carried out using coplanar welding, with high reliability; 6. BGA packaging is still the same as QFP and PGA, occupying too much substrate area; Intel Corporation adopts ceramic pin grid array packaging

1. PBGA (Plastic BGA) substrate: Generally a multi-layer board composed of 2-4 layers of organic materials. In the Intel series of CPUs, Pentium II, III, and IV processors all adopt this packaging form. In the past two years, another form has emerged: directly binding ICs to boards, which are much cheaper than regular prices and are generally used in fields such as games that do not have strict quality requirements. 2. CBGA (CeramicBGA) substrate: refers to a ceramic substrate, and the electrical connection between chips and substrates is usually installed using FlipChip (FC). In the Intel series of CPUs, Pentium I, II, and Pentium Pro processors have all adopted this packaging form. 3. FCBGA (FilpChipBGA) substrate: Hard multilayer substrate. 4. TBGA (TapeBGA) substrate: The substrate is a ribbon soft 1-2 layer PCB circuit board. 5. CDPBGA (Carity Down PBGA) substrate: Refers to the chip area (also known as the cavity area) with a square depression in the packaging center.

The substrate or intermediate layer is a very important part in BGA packaging. In addition to being used for interconnection wiring, it can also be used for impedance control and integration of inductors, resistors, and capacitors. Therefore, the substrate material is required to have high Glass transition temperature rS (about 175~230 ℃), high dimensional stability, low moisture absorption, good electrical performance and high reliability. The metal film, insulation layer, and substrate medium also have high adhesion performance. 1. Packaging process flow of PBGA wire bonding ① Preparation of PBGA substrate Laminate extremely thin (12-18) on both sides of BT resin/glass core board μ M thick copper foil, followed by drilling and through hole metallization. Create graphics on both sides of the substrate using conventional PCB and 3232 technology, such as guide strips, electrodes, and solder zone arrays for installing solder balls. Then add a solder mask and create a pattern to ex

QFN is a kind of non -quoted feet packaging, which is square or rectangular. There is a large -area naked pad in the center of the packaging at the center of the packaging to conduct heat. The electrical conductivity pad with electrical links around the packaging periphery around large pads. Because QFN packaging does not have gull -wing -like leads like the traditional SOIC and TSOP packaging, the conductivity between the internal pins and the pads is short, the self -sense coefficient and the wiring resistance in the packaging body are very low, so it can provide excellent electrical properties. In addition, it also provides excellent heat dissipation performance through the exposed lead frame pad. The pad has a direct cooling channel to release the heat in the package. The heat dissipation pad is usually welded directly on the circuit board, and the heat dissipation of the PCB can help spread the excess power consumption to the copper connecting floor, thereby absorbing excess h

The thickness of the mesh board determines the amount of welded paste printing on PCB. Too many welded paste will cause the bridge to connect when the return welding. Therefore, it is recommended that the QFN package of 0.5mm spacing uses a net board with a thickness of 0.12mm thickness and a 0.65mm spacing QFN packaging with a net board with a thickness of 0.15mm. It is recommended that the mesh opening size can be appropriately smaller than the pad to reduce the occurrence of the welded bridge connection. As shown in Figure 5. (2) Netboard design of heat dissipation pads When welding the exposed pads at the bottom of the chip and the hot pads on the PCB, the gas in the pores and the gas in large -sized pads will overflow due to the heat pores and large -sized pads. All kinds of defects (such as sputtering, welding balls, etc.), but it is almost impossible to eliminate these pores, only reduce the pores to the lowest amount. Therefore, in the design of the mesh area of the hot pa

Because the qfn's solder joints are below the packaging body, and the thickness is thin, X -Ray cannot detect the QFN solder point less tin and the opening of the road. It can only be judged as possible by the external welding joint situation. However, the current QFN welding The determination standards of the point part of the point part of the side have not yet appeared in the IPC standard. With no more ways for the time being, the testing stations that rely on post -production will be relying on the after -production section to judge the quality of welding. From the X -Ray images in Figure 6, the difference between the side part is obvious, but the image of the bottom part of the performance of the welding point performance is the same, so this brings problems to the X -ray detection and judgment. The use of electric iron to add tin, which increases only the side part, which impacts on the bottom part, X -Ray still cannot judge. Judging from the local magnifying of the appearan

For the repairs of QFN, because the welding point is completely at the bottom of the component packaging, any defects such as bridges, roads, and tin balls need to be moved away, so it is somewhat similar to the repairs of BGA. QFN is small in size, light weight, and they are used on high -density assembly boards, making it more difficult to repairs than BGA. At present, QFN repairs are still a part of the urgent development and improvement of the entire surface installation process. In particular, it is necessary to use welded paste A reliable electrical and mechanical connection between QFN and the printed board is indeed difficult. At present, there are three kinds of feasible coating ointments: one is to use the traditional use of the small silk net printing solder balla Print the welding balm directly on the pad of the component. The above methods need to be very skilled to repair the workers to complete this task. The choice of repairs equipment is also very important. It mu

The current trend of electronic products, in a small component or whole machine, constantly integrates more and more devices and functions. Hybrid integration technology has become one of the key technologies that increase the packaging density of source and passive devices. In the mixed integration of various manufacturing steps, the device and the circuit are interconnected, some passive devices such as resistors, such as resistors, are directly made of thick film or film process on the substrate. There are many important parameters of the design of the layout of the mixed integrated circuit board; the width of the wires, the routing of the wire and the keyboard, the height of the bonding coincidence, the height of the bonding leader, and the heat consumption must be considered. The thick -membrane integrated circuit process, the interconnection between the device and the circuit, the wires and resistors are on the substrate, and the various functional pulp is printed and sinte

Over the years, the industry is committed to developing the advantages of hybrid integration circuit technology, but has not made a breakthrough in manufacturing costs. Therefore, the printed board assembly process is still the best choice in the complex circuit installation. It is undoubtedly easy to improve the connection process on the naked chip board to make a directly -connected key on the nude chip board. The COB chip direct -board assembly technology is first used for digital clocks, watches. Each printed and circuit board is equipped with a chip, which is now widely used in digital cameras, calculators, telephone cards and various smart cards. Cob is complexCircuit components are equipped with a printer module of 5,000 LEDs and IC -driven combinations. Advanced data processing circuit 32BithP9000 computer motherboard installation 22 ICs and one MODEM circuit and other products have expanded their applications. Today, the multi -chip process with more than 100 chips in a

The current trend of electronic products, in a small component or whole machine, constantly integrates more and more devices and functions. Hybrid integration technology has become one of the key technologies that increase the packaging density of source and passive devices.In the mixed integration of various manufacturing steps, the device and the circuit are interconnected, some passive devices such as resistors, such as resistors, are directly made of thick film or film process on the substrate. There are many important parameters of the design of the layout of the mixed integrated circuit board; the width of the wires, the routing of the wire and the keyboard, the height of the bonding coincidence, the height of the bonding leader, and the heat consumption must be considered.The thick -membrane integrated circuit process, the interconnection between the device and the circuit, the wires and resistors are on the substrate, and the various functional pulp is printed and sintered. The

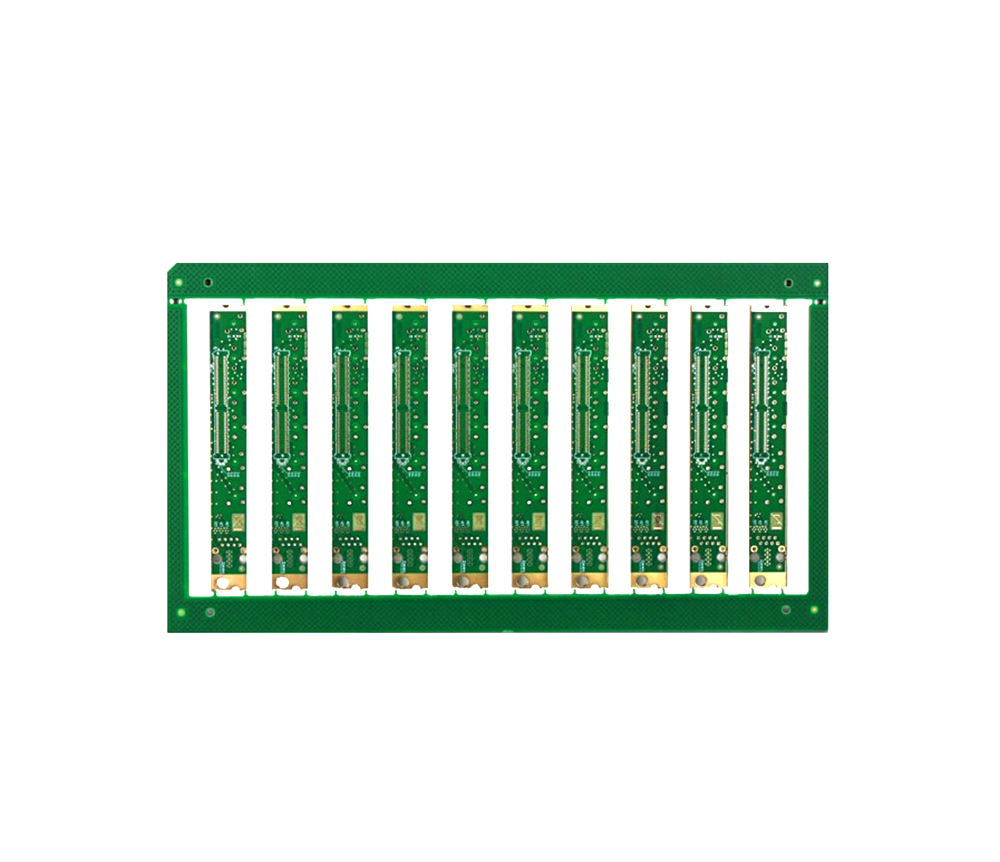

In the process of PCB connection, the traditional manual folding board is used. Although the timeliness is fast, the differences in the power of the manual folding and the position of the angle of the folding board are often caused. The destruction of the road is given this, the PCB fully automatic section machine, the latest gas and electrical lightweight design is used to complete the cutting stress cutting itinerary at one time, which is especially suitable for cutting precision SMD or thin plates. Bowwaves and microcrack are used to use the wedge -shaped tool linear plate to minimize the shear stress, so that the sensitive SMD components, and even the capacitance can not be affected, and the potential quality risk of the product is minimized. The cutting itinerary is below 1-2mm, and there is no concern for operational safety. The knife is made of high-speed steel precision grinding. It can be repeatedly grinded and used for thin plates without V-CUT. SMT production process is

QFN (QUAD FLAT no-Leadpackage, square flat without quotes), one of the surface packaging packaging. Most of them are now called LCC. QFN is the name stipulated by the Japanese Electronic Machinery Industry Association. The enclosure is equipped with an electrode contact. Because there is no pitch, the stickers are smaller than QFP and the height is lower than QFP. However, when the printed substrate and the package are generated, it cannot be relieved at the electrode contact. Therefore, the electrode contact is difficult to get the pins of QFP, generally from 14 to 100. There are two types of materials: ceramics and plastic. When there are LCC marks, they are basically ceramic QFN. The center of the electrode contact is 1.27mm. Plastic QFN is a low -cost packaging of glass epoxy resin printing substrate substrate. In addition to 1.27mm, there are two types: 0.65mm and 0.5mm. This packaging is also called plastic LCC, PCLC, P-LCC, etc.

QFN packaging has excellent thermal performance, mainly because there is a large area of heat dissipation pads at the bottom of the packaging. In order to effectively transmit heat from the chip to PCB, the bottom of the PCB must be designed with the corresponding heat dissipation pads and heat dissipation. The heat dissipation pads provide a reliable welding area, and the perfunction provides heat dissipation channels. The size of the heat dissipation pads is at least matched with the exposure of the component. However, various other factors are needed, such as avoiding bridges with the peripheral pads. The amount and size of the heat dissipation depends on the application of the package, the size of the chip power, and the electrical performance requirements. It is recommended that the distance between heat dissipation is 1.0mm to 1.2mm, and the size of the perforated is 0.3mm to 0.33mm. There are four design forms of heat dissipation over -the -pels: such as using a dry membran

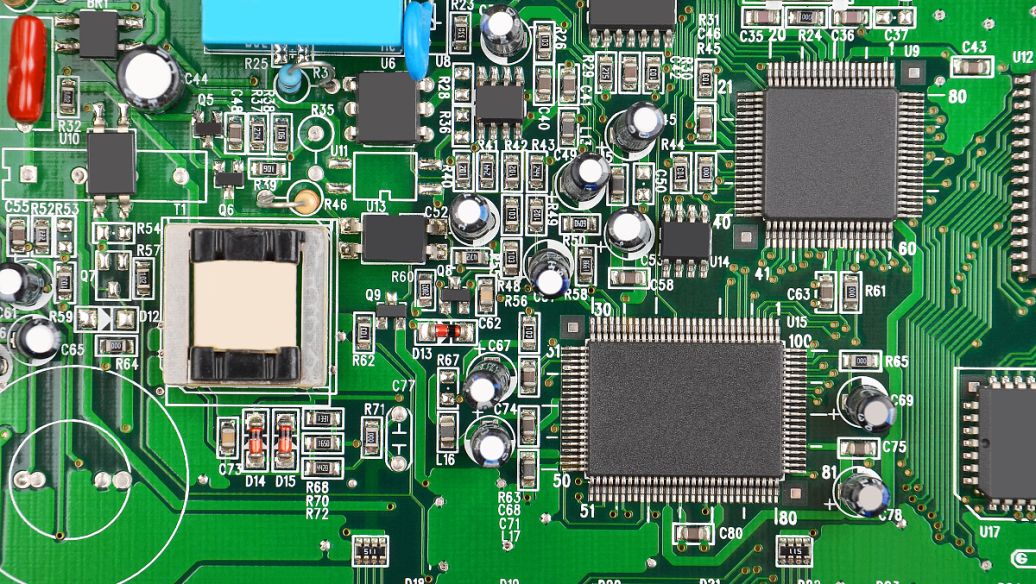

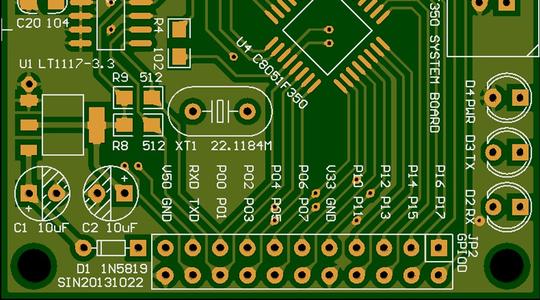

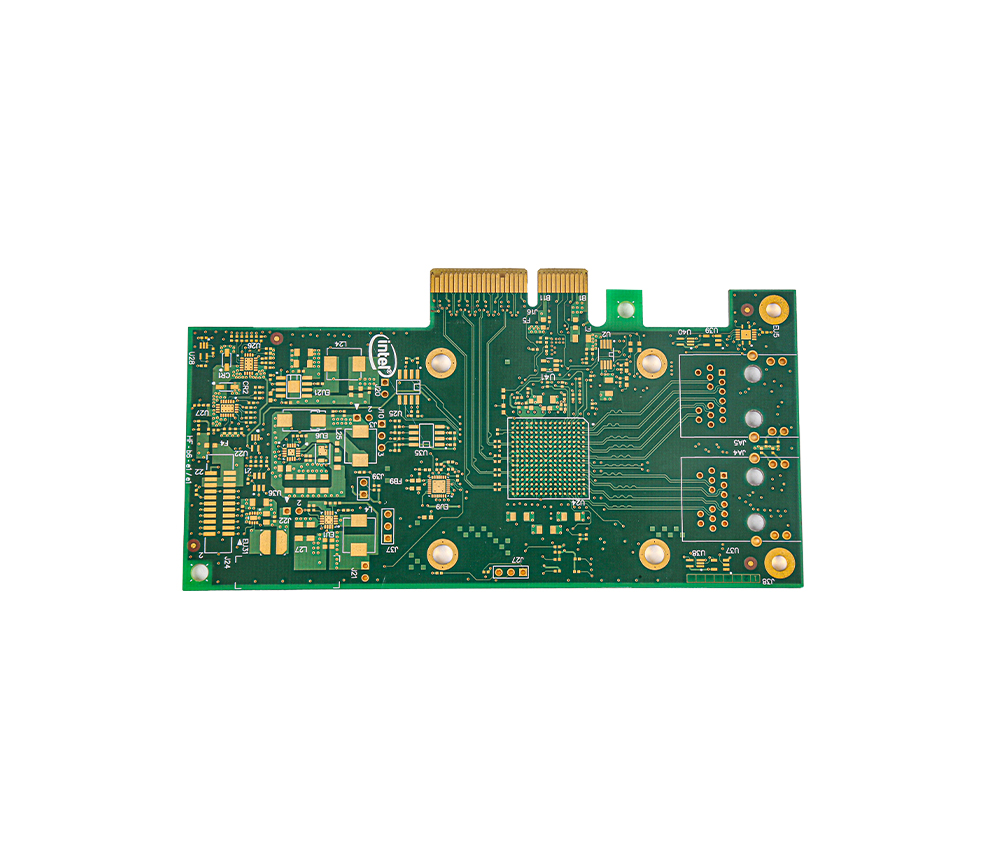

PCB bare board is the abbreviation of Printed Circuit Board. The Chinese name is printed circuit board, also known as print circuit board, printed circuit board. It is an important electronic component, a support body for electronic components, and a provision of electronic components electrical connection. By. Because it is made of electronic printing, it is called a "print" circuit board. As electronic devices are becoming more and more complicated, there are naturally more and more parts required, and the lines and parts on the PCB are becoming more and more dense. Naked plates (there are no parts on it) are often called "printing line board Printed Wiring Board (PWB)". The substrate of the board itself is made of insulation and insulation, and it is not easy to bend the material. The small line materials that can be seen on the surface are copper foil. The originally copper foil was covered on the entire board, and part of the part was carved during the manufacturing process.

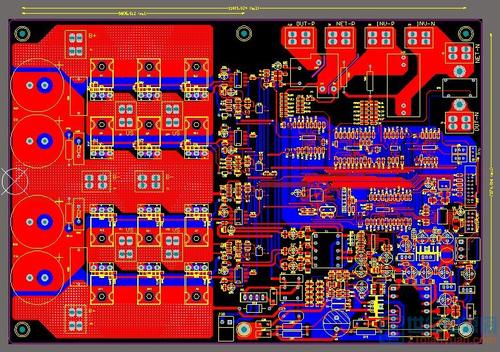

1. There are many dedicated PCB drawing software, such as Protel, etc., you can draw a multi -layer (including double -sided) circuit board diagram. The line is connected to achieve cross -wiring to facilitate typesetting. After the typesetting is completed, it can be handed over to the circuit board of a specific circuit. 2. The double -sided circuit board should be drawn into a circuit schematic in turn, which can be divided into two steps. Step 1: First, draw the symbols of the main components such as IC, etc. The position of the circuit board is drawn on the paper, and the connecting lines and peripheral components are appropriately decorated and drawn to complete the sketch. Step 2: Analyze the principle and organize the circuit diagram according to the habit of drawing. You can also use the circuit schematic diagram software to connect the components and then use its automatic typesetting function to organize. The lines on both sides of the double panel should be accurately

During the long-term production control process, we found that the aperture reached 0.15-0.3mm, and the proportion of the plug holes increased by 30%. 1. The problem of plug holes in the process of hole formation: During the printed board processing, most of the small holes of 0.15-0.3mm still use the mechanical drilling process. In long -term inspection, when we found drilling, we left in the pores The following are the main reasons for drilling holes: When the holes appear in small holes, due to the small pore diameter, high -pressure water washing and chemical cleaning before sinking copper were difficult to remove the debris in the small holes. Essence When drilling the thickness of the stacked layer, the suitable drilling mouth and pad are used to keep the substrate clean. The pads are not reused. The effective vacuum effect (using an independent vacuum control system) is a factor that solves the plug hole.

The drill head is first poured on the copper plate, and then passes through the chemical sinking copper, and the electroplating copper forms a coating hole. The two plays a vital role in the metal of holes. 1. Chemical sinking bronze machine: In the process of double -sided and multi -layer printed board manufacturing, it is necessary to metallize non -conductive nude holes, that is, chemical sinking copper to make it a conductor. Chemical sinking solution is a catalytic "oxidation/restoration" reaction system. Under the catalysis of metal particles such as AG, PB, AU, CU, copper is deposited. 2. Copper plating mechanism: The electroplating definition is to use the power supply to push the coating on the surface of the cathode on the surface of the cathode in the solution. Copper plating is a "oxidation/restoration" reaction. The copper metal anode in the solution oxidize the copper metal on its surface and become copper ions. On the other hand, a reaction is generated on the c

For high -tech development, people need high performance, small volume, and many functions, which prompts the manufacturing of the line board to manufacture to light, thin, short, small development, limited space, and more functions. The wiring density becomes larger. Small. From 1995 to 2007, the minimum pores of mechanical drilling batch capacity fell from 0.4mm to 0.2mm or even smaller. Metal -tonged pores are getting smaller and smaller. The metallic holes depended on the inter -layer interconnection are directly related to the reliability of the printing board. With the narrowing of the aperture, there are no miscellaneous objects that have no effect on the large pores, such as grinding brushing debris and volcanic ash. Once they remain in small holes, chemical sinking copper and electroplating copper will lose their effects. Metal -oriented fatal killer. The design of the printed circuit board is based on the circuit schematic diagram to realize the function required by the

Inquiry Now