+86 755 2794 4155

+86 755 2794 4155  sales@knownpcb.com

sales@knownpcb.com

-

Shenzhen KNOWNPCB Technology Co., Ltd.

+86 755 2794 4155

+86 755 2794 4155  sales@knownpcb.com

sales@knownpcb.com

Have you noticed that now more and more of our lighting is using led lighting.What is LED? Compared to the traditional light bulbs, LEDs have lower power consumption, longer lifetime and higher energy efficiency. In the PCB industry,when we say LED PCB, it refers to the pcb used for LED lighting, if you are looking for a suitable LED PCB for your lighting system, this article may bring you something. WHAT ARE LEDS COMPOSED OF?LED is an initial light-emitting diode that produces light when an electric current passes through. LEDs typically have negative and positive electrodes, which generate light in the visible light region.The LEDS are glued to the PCB by soldering process and have electrical connections for lighting.Since light-emitting diodes dissipate a lot of heat when they are in use, when you are designing LED, the metal core is usually the best choice for LED PCB, it is because that it dissipates heat more faster. Among them, the metal material aluminum is the most widely used

The direct reason for the temperature rise of printed boards is due to the presence of circuit power consuming devices. Electronic devices have varying degrees of power consumption, and the heating intensity varies with the size of power consumption. Two phenomena of temperature rise in printed boards: (1) Local or large-scale temperature rise; (2) Short term or prolonged temperature rise. When analyzing the thermal power consumption of PCB circuit boards, it is generally analyzed from the following aspects. 1. Electrical power consumption (1) Analyze the power consumption per unit area; (2) Analyze the distribution of power consumption on PCB circuit boards. 2. Structure of printed boards (1) The size of the printed board; (2) The material of the printed board. 3. Installation method of printed boards (1) Installation method (such as vertical installation, horizontal installation); (2) Sealing condition and distance from the casing.

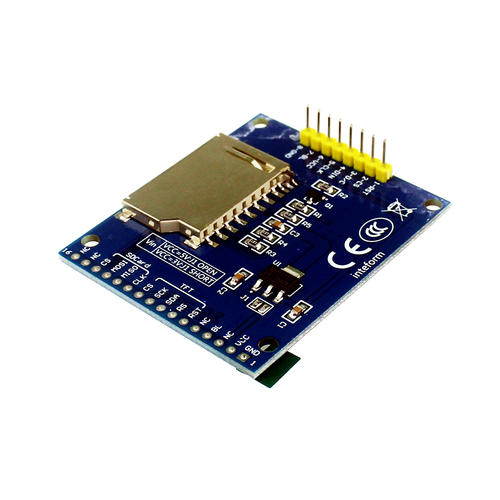

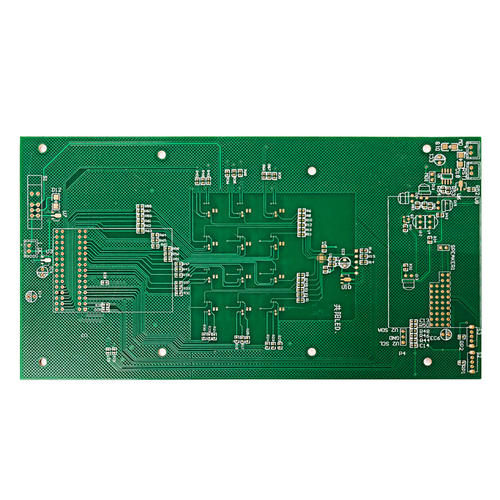

As pcb design is more and more commonly used in existing development boards, and sub boards are used to drive hydraulic devices and servo motors or perform tasks according to light, motion and sound, the design trend of printed circuit boards gradually tends to Open-source hardware mode and control system. Another major trend in PCB design is the explosive growth of development boards. In October 2013, a survey was conducted on PCB designers from around the world, including professional engineers from 42 different countries. The survey results show that nearly two-thirds of the respondents (64%) believe that the development board has to some extent reduced their demand for customized PCB design. On the surface, this result poses a threat to the development of PCB design, but in reality, printed circuit board design tools are being increasingly applied in development board design. However, since its inception, the design of printed circuit boards has not undergone fundamental chang

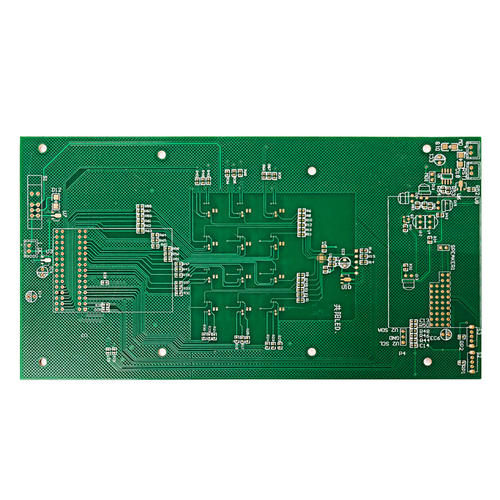

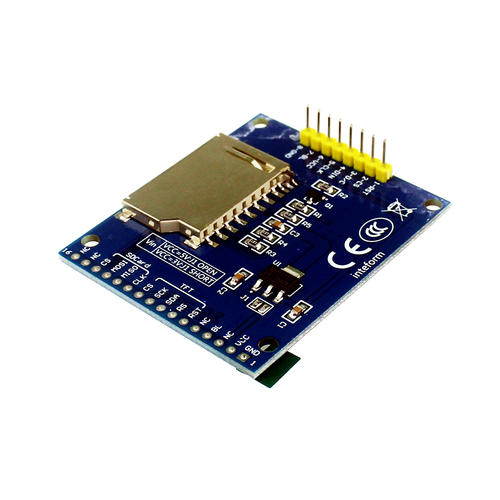

These electronic products aim to save space and make them lighter and more compact. Durable and to achieve good performance, it is necessary to cancel the previous wire connection and switch to a printed circuit board. PCB meets the requirements of space, performance, and reliability. Not every electrical appliance requires a circuit board, simple appliances may not require a circuit, such as an electric motor. However, electrical appliances with specific functions typically require circuit boards to be implemented, such as televisions, radios, computers, etc. There is also a PCB at the bottom of the Rice cooker and a governor in the fan. PCB board usually refers to a hard circuit board, mainly used for computer motherboards, mouse boards, graphics cards, office equipment, printers, copiers, remote controls, various chargers, calculators, digital cameras, radios, TV motherboards for household appliances, limited TV amplifiers, mobile phones, washing machines, electronic scales, t

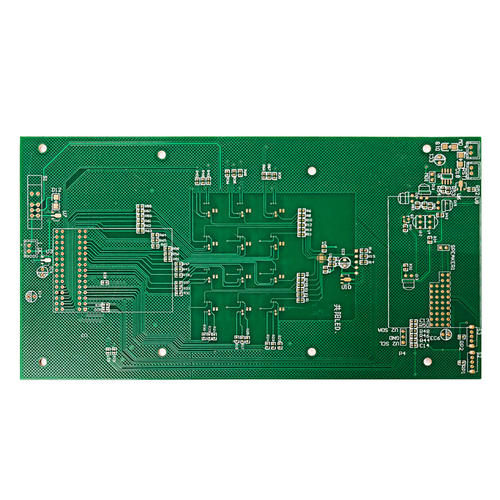

Single sided PCB sample delivery time: Normal delivery time is 2-3 days, and can be expedited within 12 or 24 hours Sample delivery time for double-sided PCB board: Normal delivery time is 2-3 days, and can be expedited within 12 or 24 hours Sample delivery time for the fourth layer circuit board: normal delivery time 4-5 days, with 12, 24, and 72 hours for expedited delivery Six layer circuit board sample delivery time: normal delivery time of 6-7 days, with 72 hours for expedited delivery LED aluminum substrate sample lead time: Normal lead time 3-4 days, can be expedited within 72 hours Delivery time for small batch sampling of PCB circuit boards: 5-6 days within 5 square meters; 6-7 days within 10 square meters; Over 10 square meters for 8-9 days Kind reminder: 1. Except for matte black, matte green, and purple, all other colors are free of charge! 2. Place an order for payment before 18:00 on the same day, and the PCB sample delivery time will be calculated from the ne

In the PCB production process, the reservation of process edges is of great significance for subsequent SMT chip placement processing. The process side is to assist in the welding of the PCB board on both sides or on all four sides of the PCB board. It is mainly used to assist production and is not a part of the PCB board. It can be removed after the completion of PCBA manufacturing and production. Due to the fact that process edges consume more PCB boards, which increases the overall cost of the PCB, it is necessary to balance economy and manufacturability when designing PCB process edges. For some special shaped PCB boards, the original PCB boards with 2 or 4 process edges can be cleverly simplified by splicing. When designing the splicing method in SMT mounting processing, it is necessary to fully consider the track width of the SMT mounting machine. For splicing exceeding 350mm in width, it is necessary to communicate with the SMT supplier's process engineer. The main reason

For some friends who are new to aluminum substrates, there are still questions about the difference between aluminum substrates and PCB boards. Today, the editor will talk to you specifically about this question. Aluminum substrate is a metal-based copper-clad laminate with good heat dissipation function. Generally, a single panel is composed of a three-layer structure, which is a circuit layer (copper foil), an insulating layer and a metal base layer. PCB board, also called printed circuit board, is a provider of electrical connections for electronic components. PCB board is a big category, aluminum substrate is only one of the types, and the design is designed in accordance with the requirements of pcb board. The aluminum substrate we generally call is a single-sided aluminum-based PCB board with good thermal conductivity and is generally used in the LED industry. At present, the commonly used LED aluminum substrate has two sides, the white side is for soldering the LED pins, a

Everyone knows that aluminum is a kind of metal and has conductivity. How can it be used as a PCB material? This is because the aluminum substrate is composed of three layers: copper foil, insulating layer and metal aluminum. Since there is an insulating layer, can the metal layer be made of other materials besides aluminum? Such as copper plate, stainless steel, iron plate, silicon steel plate and so on. What kind of material is used for the metal substrate, in addition to considering the heat dissipation performance, but also consider the thermal expansion coefficient, thermal conductivity, strength, hardness, weight, surface condition and cost of the metal substrate. Under normal circumstances, considering the cost and technical performance, aluminum plate is an ideal choice. Available aluminum plates are 6061, 5052, 1060, etc. If there are higher thermal conductivity, mechanical properties, electrical properties and other special performance requirements, copper plates, stain

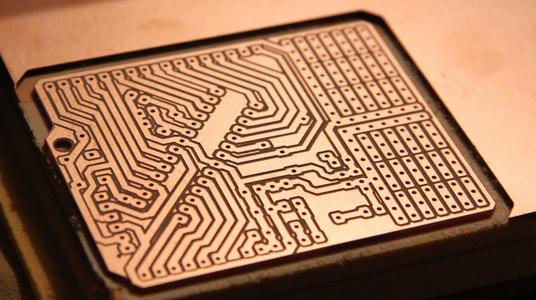

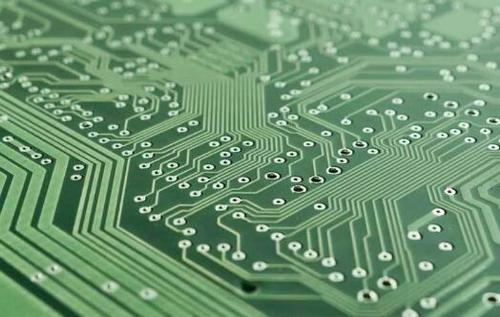

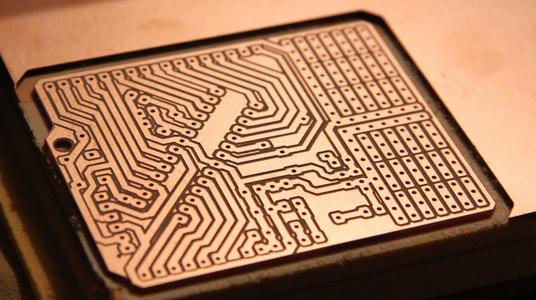

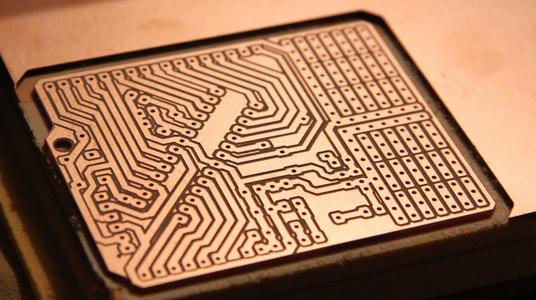

Copper foil is a kind of negative electrolytic material, a thin, continuous metal foil deposited on the base layer of the circuit board, which acts as the conductor of the PCB. It easily adheres to the insulating layer, accepts the printed protective layer, and forms a circuit pattern after corrosion. What is the role of the copper foil of the aluminum substrate? The copper foil of the aluminum substrate is also called the circuit layer of the aluminum substrate. It is the conductor of the aluminum-based circuit board and also a kind of cathode electrolytic material, which is generally deposited on the base layer of the circuit board. Thin, continuous metal foil. Copper foil has low surface oxygen characteristics and can be attached to various substrates, such as metals, insulating materials, etc., and has a wide temperature range. The copper foil of the aluminum substrate is easily adhered to the insulating layer and accepts the printed protective layer. After corrosion, the patt

The good heat dissipation performance of the aluminum substrate makes it widely used. Let the aluminum substrate manufacturers introduce the aluminum substrate in detail below. 1. Features of aluminum substrate 1. Using surface mount technology (SMT); 2. In the circuit design scheme, the heat dissipation is extremely effective treatment; 3. Reduce the operating temperature of the product, improve the power density and reliability of the product, and extend the service life of the product; 4. Reduce product volume, reduce hardware and assembly costs; 5. Replace the fragile ceramic substrate to obtain the best mechanical durability. 2, the structure of the aluminum substrate Aluminum-based copper clad laminate is a metal circuit board material, composed of copper foil, thermally conductive insulating layer and metal substrate: Copper foil: the copper clad laminate equivalent to ordinary PCB, the thickness of the circuit copper foil is loz to 10oz. Thermally conductive insul

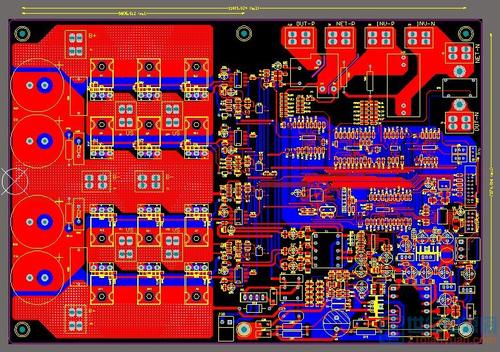

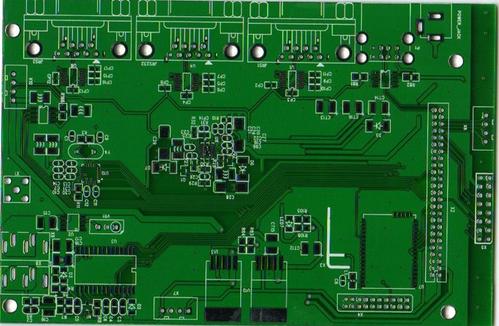

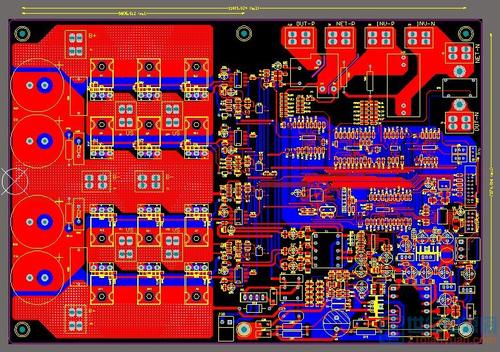

1. Enter the PCB design system and set relevant parameters Set the environmental parameters of the design system based on personal habits, such as the size and type of grid points, the size and type of cursors, etc. Generally, the default values of the system can be used. In addition, parameters such as the size and number of layers of the circuit board need to be set. 2. Generate Import Network Table The network table is a crucial bridge and link between circuit schematic design and printed circuit board design. Network tables can be generated from circuit schematics or extracted from existing electronic circuit board files. When introducing network tables, it is necessary to check and correct errors in the circuit schematic design. 3. Arrange the packaging positions of each component The automatic layout function of the system can be utilized, but it is not very complete and requires manual adjustment of the packaging position of each component. 4. Wiring the circuit board

1. There are many factors to consider when determining the stacking structure of multi-layer PCB boards. In terms of wiring, the more layers there are, the more advantageous it is for wiring, but the cost and difficulty of making boards will also increase accordingly. For manufacturers, the symmetry of the stacked structure is the focus of attention when manufacturing PCB boards, so the selection of the number of layers needs to consider various needs to achieve the best balance. For experienced designers, after completing the pre layout of components, they will focus on analyzing the wiring bottlenecks of PCBs. Analyze the wiring density of the circuit board with other EDA tools; Determine the number and type of signal layers by synthesizing the number and types of signal lines with special wiring requirements, such as differential lines and sensitive signal lines; And then based on Determine the number of internal electrical layers based on the type of power supply, isolation, a

Previously, I worked in a small electronics factory to manually attach PCB board components, which required hundreds of pieces to be attached in a day. The efficiency was very low and could not match that of a mounting machine. Because it is a small factory, there is not enough manpower, and basically every step has been done, so I have some understanding. Firstly, the engineer uses AD software to draw the PCB. After the layout is manually completed, the drawings are handed over to the manufacturer for sampling. Generally, the PCB board and its corresponding steel mesh can be sampled within 7 working days. Then, the device is purchased according to the circuit diagram provided by the engineer. Then, it is the production line. We scrape solder paste on the screen printing table. Align the silk screen of the PCB board with the steel mesh, then fix the steel mesh, and then scrape tin on the steel mesh. Apply the solder paste onto the silk screen on the surface of the PCB board, so tha

Pcb circuit board manufacturing refers to the trial production of printed circuit boards before mass production, mainly refers to the process that electronic engineers design circuits, complete PCB, and then carry out a small amount of trial production to the factory. This is the Chinese name for PCB, which is printed circuit board, also known as printed circuit board. It is an important electronic component, the support of electronic components, and the electrical connection provider of electronic components. It is called a "printed" circuit board because it is made using electronic printing technology. Pcb circuit board manufacturing refers to the trial production of printed circuit boards before mass production, mainly refers to the process that electronic engineers design circuits, complete PCB, and then carry out a small amount of trial production to the factory. This is the manufacturing of PCB circuit boards. The production quantity of PCB samples usually does not have a spe

1. To prevent short circuits caused by tin penetrating through the component surface through the through hole during PCB wave soldering; Especially when we place the via hole on the BGA pad, we must first make a plug hole and then gild it to facilitate BGA welding. 2. After the surface mounting and component assembly of the electronic factory are completed, the PCB needs to be vacuumed on the testing machine to form negative pressure: 3. Prevent surface solder paste from flowing into the holes, causing false soldering and affecting the installation of PCB circuit boards; 4. Prevent solder beads from popping out during peak soldering, causing short circuits on the PCB circuit board; 5. Avoid flux residue in the through-hole

If a PCB circuit board is used in a humid environment, the air contains a large amount of moisture. When the moisture is too high, it will turn into water droplets and fall onto the PCB circuit board. After the water droplets scatter on the circuit board, they will attach to various pins or printed wires of electronic components. After the printed wire is soaked with water droplets, especially when the signal transmission line is relatively small and soaked for a period of time, there will be mold breakage of the printed wire, causing the circuit board to malfunction during the next operation. The causes of circuit board failures caused by moisture are classified into three categories: 1. Causing changes in circuit parameters in the PCB circuit board, leading to PCB circuit board failure; 2. Causing the circuit in the PCB circuit board to be in a short circuit state, causing the PCB circuit board to malfunction; 3. Causing open circuit in signal processing or transmission line

1、 Introduction: With the continuous improvement of human requirements for living environment, the environmental issues involved in PCB production process are particularly prominent. The topic of lead and bromine is currently the most popular; Lead-free and halogen-free technologies will affect the development of PCBs in many ways. Although at present, the changes in the surface treatment process of circuit boards are not significant and may seem distant, it should be noted that long-term slow changes will lead to significant changes. With the increasing demand for environmental protection, the surface treatment process of PCBs is bound to undergo significant changes in the future. 2、 The purpose of surface treatment is to ensure good weldability or electrical performance, which is the most basic purpose of surface treatment. Due to the tendency of copper in nature to exist in the form of oxides in the air, it is unlikely to remain the original copper for a long time, so other tr

The switch regulator used for voltage conversion uses inductance to store energy when it falls. These inductors are usually very large in size and must be positioned in the printed circuit board (PCB) planning of the switch regulator. This task is not difficult, as the current passing through the inductor may change, but it is not an instantaneous change. Changes can only be continuous and usually relatively slow. The switching regulator switches current back and forth between two different paths. This switching is very fast, and the detailed switching speed depends on the duration of the switching edge. The wiring through which switching current flows is called a thermal circuit or AC current path, which conducts current in one switching state and does not conduct current in another switching state. In PCB planning, the thermal circuit area should be small and the path should be short to minimize parasitic inductance in these wiring. Parasitic wiring inductance can generate useles

Printed circuit boards are the most active industry in the contemporary electronic component industry, and their industry growth rate is generally about 3 percentage points higher than that of the electronic component industry. It is expected to maintain rapid growth in 2006, with demand upgrading and industrial transfer being the basic driving forces for industry development, while varieties such as HDI boards, flexible boards, and IC packaging boards (BGA, CSP) will become the main growth points. In 2003, the output value of printed circuit boards in China was 50.069 billion yuan, a year-on-year increase of 333%, surpassing the second largest in the world, the United States, for the first time. In 2004 and 2005, China's PCB output value still maintained a growth rate of over 30%, estimated to reach 86.9 billion yuan in 2005, far exceeding the growth rate of the global industry. Flexible circuit boards are rapidly developing towards miniaturization in electronic devices represen

The suitability of PCB circuit boards in terms of system signal, connection distance, and capacitive load is considered before deciding whether to use transmission lines. What types of transmission lines are commonly used in PCB circuit boards? The main types of transmission lines for PCB circuit boards are: (1) Coaxial cables and twisted pair cables: They are often used for the connection between PCB circuit board transmission systems and systems. The characteristic impedance of coaxial cables is typically 50 Ω and 75 Ω, while twisted pair cables are typically 110 Ω. (2) Microstrip on PCB The Microstrip is a strip conductor (signal line). It is separated from the ground plane by a dielectric. If the thickness, width, and distance from the ground plane of a line are controllable, its characteristic impedance can also be controlled. (3) Strip lines in printed boards A strip line is a copper strip line placed between two conductive planes in the middle of a dielectric medium. I

1. Pad design (1) When designing plug-in component pads, the pad size should be designed appropriately. If the solder pad is too large, the solder spreading area is large, and the formed solder joints are not full, while the surface tension of the smaller solder pad copper foil is too small, and the formed solder joints are non wetting solder joints. The fit gap between the aperture and the component lead is too large, which is prone to false soldering. When the aperture is 0.05-0.2mm wider than the lead and the diameter of the solder pad is 2-2.5 times the aperture, it is an ideal welding condition. (2) When designing solder pads for SMD components, the following points should be considered: in order to eliminate the "shadow effect" as much as possible, the solder end or pin of SMD should be facing the direction of the tin flow to facilitate contact with the tin flow and reduce false soldering and solder leakage. For smaller components, they should not be placed behind larger co

Inquiry Now