+86 755 2794 4155

+86 755 2794 4155  sales@knownpcb.com

sales@knownpcb.com

-

Shenzhen KNOWNPCB Technology Co., Ltd.

+86 755 2794 4155

+86 755 2794 4155  sales@knownpcb.com

sales@knownpcb.com

Have you noticed that now more and more of our lighting is using led lighting.What is LED? Compared to the traditional light bulbs, LEDs have lower power consumption, longer lifetime and higher energy efficiency. In the PCB industry,when we say LED PCB, it refers to the pcb used for LED lighting, if you are looking for a suitable LED PCB for your lighting system, this article may bring you something. WHAT ARE LEDS COMPOSED OF?LED is an initial light-emitting diode that produces light when an electric current passes through. LEDs typically have negative and positive electrodes, which generate light in the visible light region.The LEDS are glued to the PCB by soldering process and have electrical connections for lighting.Since light-emitting diodes dissipate a lot of heat when they are in use, when you are designing LED, the metal core is usually the best choice for LED PCB, it is because that it dissipates heat more faster. Among them, the metal material aluminum is the most widely used

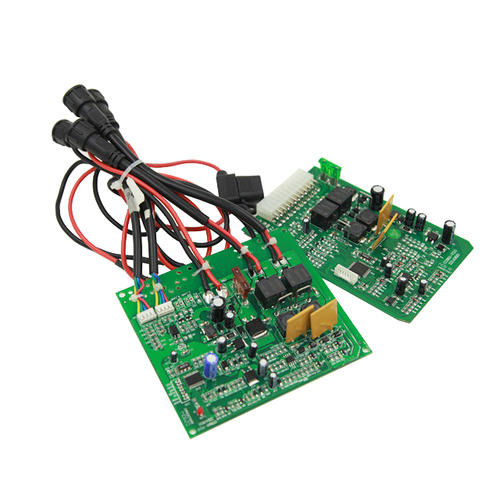

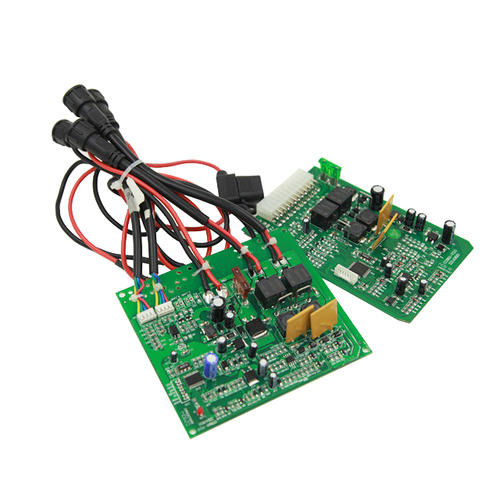

PCBA, which refers to the assembly, mounting, and welding of PCB components, is the core process in PCBA. So, what are the precautions for PCB processing by Shenzhen circuit board manufacturers? 1、 Transportation: To prevent damage to PCBA, during transportation, it is necessary to: 1. Container: Anti static turnover box. 2. Isolation material: anti-static pearl cotton. 3. Placement spacing: There is a distance greater than 10mm between boards and between boards and boxes. 4. Placement height: There is a space greater than 50mm from the top surface of the turnover box. 2、 PCBA processing and washing requirements: 1. Board surface requirements: Clean, with no stains on Wuxi beads and component pins. 2. Devices that should be protected during board washing: wires, connecting terminals, relays, switches, polyester capacitors, and other devices. 3、 Component requirements: All components must not exceed the edge of the PCB board after installation. 4、 Welding requirements: 1.

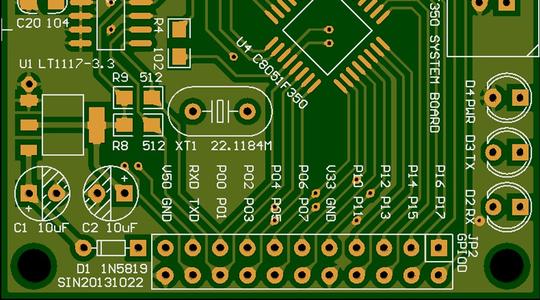

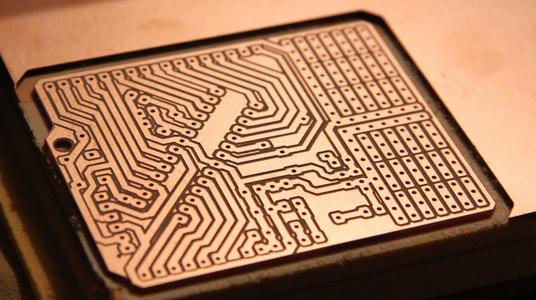

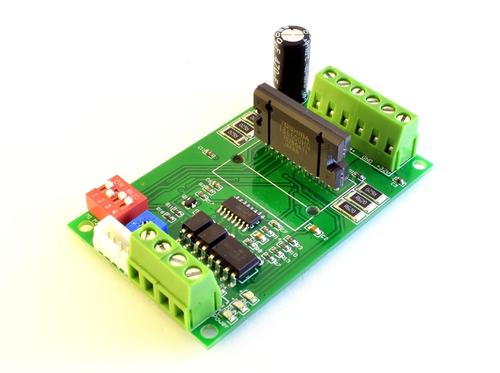

Printed circuit boards (PCBs) are an indispensable part of electronic devices, and their performance and reliability directly affect the operation of the entire system. PCB (Printed Circuit Board), also known as Printed Circuit Board (PCB) in Chinese, is an important electronic component that supports electronic components and serves as a carrier for the electrical interconnection of electronic components. Due to its use of electronic printing technology, it is called a "printed" circuit board. Cabling is a key step in PCB design, which determines the performance and stability of the circuit board. This article will explore the wiring principles and practical techniques of PCB boards to help engineers achieve better results in design. Wiring principles Following the circuit schematic diagram Wiring should strictly follow the circuit schematic to ensure correct wiring connections and prevent short or open circuit problems. During the wiring process, each component in the circuit

During the production process of PCB circuit boards, due to the inability of printed solder paste and solderless PCB assembly boards to fix the test end of thermocouples, it is necessary to use the actual welded product for temperature testing. So, how to conduct PCB board temperature limit testing? 1、 Select test points: Based on the complexity of the PCB assembly board and the number of channels in the collector, select at least three representative temperature test points that can reflect the high, medium, and low temperatures on the PCB surface assembly board. 2、 Fixed thermocouple: Use high-temperature solder to weld the test ends of multiple thermocouples onto the test points (solder joints), and the solder on the original solder joints must be cleaned before welding; Alternatively, use high-temperature adhesive tape to attach the test ends of the thermocouples to each temperature test point on the PCB. 3、 Insert the other end of the thermocouple into the machine table at

The problem of blackening of the electroplating gold layer often occurs, which affects the quality and performance of the circuit board. So, what are the reasons for the blackening of the electroplating gold layer on PCB board copying? 1. Thickness control of nickel plating layer PCB electroplating gold layer is generally very thin, reflected on the surface of electroplating gold, many of which are caused by poor performance of nickel electroplating. Generally, a thin nickel plating layer can cause the appearance of the product to turn white and black. Generally, it is necessary to electroplate the nickel layer thickness to around 5UM to be sufficient. 2. Condition of plating nickel cylinder solution If the nickel cylinder solution is not well maintained for a long time and carbon treatment is not carried out in a timely manner, the nickel layer electroplated will easily produce flaky crystals, increase the hardness and brittleness of the coating. Serious problems can result in

The PCB circuit board is only a complete device after processing, and can be used in applied electronic products. The PCBA process is the combination of SMT processing and DIP processing. Today, the editor will share with you what processes are included in the processing of PCB by Shenzhen circuit board manufacturers. 1、 Single sided DIP insertion PCB boards that require plugins can be welded and fixed by workers after inserting electronic components, followed by wave soldering, cutting and washing the board. 2、 Single sided SMT mounting Add solder paste to the component pad, and after the solder paste printing is completed, the relevant electronic components are reflow soldered and then reflow soldered. 3、 Single sided mixed packaging PCB boards are printed with solder paste, installed with electronic components and fixed by reflow soldering. After quality inspection is completed, DIP insertion is performed, followed by wave soldering or manual soldering. 4、 Double sided SM

PCBA is the entire process of SMT loading through PCB empty boards, followed by DIP plugins; Placement and welding are the core processes in PCBA. So, what are the requirements for chip mounting and welding in the PCBA processing process? 1、 PCBA SMT processing process requirements: 1. Based on customer Gerber files and BOM sheets, create SMT production process files and generate SMT coordinate files. 2. Check if all production materials are ready and confirm the PMC plan for production. 3. Conduct SMT programming and create a homepage for verification. 4. According to the SMT process, make laser steel mesh. 5. Perform solder paste printing to ensure that the printed solder paste is uniform and of good thickness. 6. Mount the components onto the circuit board using an SMT mounting machine, and perform online AOI testing if necessary. 7. Set a perfect reflow soldering furnace temperature curve to allow the circuit board to flow through reflow soldering, and the solder paste

Many beginners are always confused about the rules and requirements for PCB circuit board sampling fees. What materials do they need to provide? Let the engineer explain this process to you: 1、 How much do I charge for PCB sampling? Firstly, it depends on what type of board is used, such as FR4, high TG board, and brand benefits. The plates are different, and the prices are also different. In addition, according to the design drawings, the smaller the line width and spacing, the more holes there are, and the more precise it is, the higher the cost. Looking at the surface treatment, sinking gold and gilding are more expensive than tin and OSP. Four Look at Quantity . According to the delivery date, PCB boards that require expedited delivery are cheaper than those that require regular delivery. 2、 What do I need to provide for PCB sampling? Information that needs to be provided to the manufacturer for quotation, drawings generally provide GEBER documents, with clear process requ

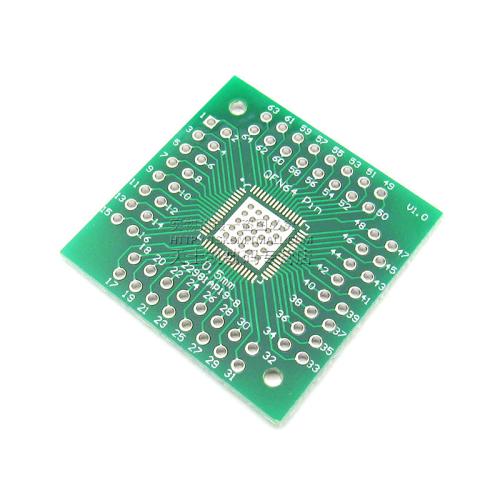

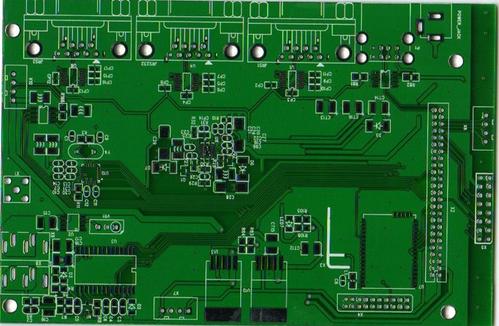

With the development of PCB technology towards high density and refinement, the role of multi-layer PCB boards is becoming increasingly important and widely used in various fields. Below is the engineer's interpretation of several common questions about multi-layer PCB circuit boards: 1. How many layers can a multi-layer PCB board have at most? PCB boards were initially mainly composed of single or double panels, but later with the development of technology, multi-layer PCB boards were needed to achieve the interaction of multi-layer circuits. Components range from simple single sided boards to 4, 6, 8, 10, 12, and even 22 or more layers. There is no conclusion regarding the maximum number of layers on a multi-layer PCB board. For research and development institutions, the number of layers of a PCB depends on the product requirements and functions implemented by the electronic PCB application. 2. Is it better to have more layers of multi-layer PCB boards? Generally speaking, the

PCB ink plays a role in protecting the copper foil during the production of PCB circuit boards, preventing the copper skin from being exposed, thereby affecting the subsequent processes; The commonly used ink colors are white oil, green oil, black oil, blue oil, red oil, and butter. So, what are the precautions for using PCB ink? In any case, the temperature of the ink must be maintained between 20-25 ℃, otherwise it will affect the viscosity of the ink and the quality and effectiveness of screen printing. Especially when ink is stored outdoors or at different temperatures, it must be placed at ambient temperature for a few days before reuse or until the ink barrel reaches the appropriate temperature for use. 2. Before use, the ink must be thoroughly and carefully mixed manually or mechanically. If air enters the ink, it should be left to stand for a period of time before use; If dilution is required, first mix thoroughly and then test its viscosity. The ink bucket must be sealed

Many newcomers often confuse nickel palladium plating with nickel gold plating. So, what is the difference between PCB sample nickel palladium plating and nickel gold plating? Nickel palladium plating is a non selective surface processing process that involves depositing a layer of nickel, palladium, and gold onto the surface of the copper layer of the printed circuit using chemical methods in PCB sampling. Electroplating nickel gold refers to the process of making gold particles adhere to PCB boards through electroplating, which is also known as hard gold due to its strong adhesion; This process can greatly increase the hardness and wear resistance of PCBs, effectively preventing the diffusion of copper and other metals. The difference between chemical nickel palladium gold and electroplating nickel gold: Similarities: 1. Both belong to important surface treatment processes in PCB sampling; 2. The main application field is wiring and connection technology, which is suitable

Aluminum substrate is a metal based copper clad plate with good thermal conductivity, electrical insulation performance, and mechanical processing performance. Let the Shenzhen PCB manufacturer take you to understand what aluminum substrates are. 1、 Characteristics of aluminum substrate 1. Adopting surface mount technology; 2. Extremely effective treatment of thermal diffusion; 3. Reduce product operating temperature, improve product power density and reliability; 4. Reduce product volume and assembly costs; 5. Replace fragile ceramic substrates. 2、 Structure of aluminum substrate The aluminum substrate consists of copper foil, thermal insulation layer, and metal substrate: Copper foil: The thickness of the copper foil for the circuit is between loz and 10oz. Thermal insulation layer: It is a low thermal resistance thermal insulation material. Metal substrate: generally aluminum based copper clad plate and traditional epoxy glass cloth laminated plate. Explanation: 1.

PCB circuit boards are prone to malfunctions during use, which involves maintenance. So, what are the issues to pay attention to when repairing PCB circuit boards? 1、 Understand the vulnerable components on the circuit board 1. Areas with unreasonable design are most prone to malfunctions Firstly, there is a heat dissipation issue, as many PCB boards are damaged due to poor heat dissipation design; Secondly, there is copper foil wire. The copper foil of circuit board power lines with poor quality is very thin and easily burnt out due to overcurrent. 2. Frequently used areas are prone to malfunctions For example, the drive motor of the circuit board, the shaft, the switch tube of the switching power supply, the operation panel, etc. 3. Components with heavy loads, high power, and high operating voltage are most likely to malfunction The power supply, driving circuit, power control device, operational amplifier, etc. of the circuit board are the most easily damaged. 4. Protec

The anti-interference ability of PCB circuit boards can affect the effective performance of electronic devices, and the anti-interference ability of PCB circuit boards is closely related to specific circuits. So, what are the anti-interference measures for PCB circuit boards? 1. Principle of ground wire design: If there are both logical and linear circuits on the PCB circuit board, they should be separated as much as possible; The grounding of low-frequency circuits should be connected in parallel with a single point as much as possible. If there are difficulties in actual wiring, partial series connection can be used before connecting to the ground. 2. Closed loop composed of grounding wires: PCB circuit boards composed solely of digital circuits, with their grounding circuits arranged in a clustered loop, can mostly improve their noise resistance. 3. On the premise that the speed can meet the requirements, try to reduce the crystal oscillator of the microcontroller and select lo

Due to cost and technical reasons, PCBs may encounter a large number of failure issues during production and application. In order to understand the cause of the failure and find a solution to the problem, it is necessary to conduct a failure analysis of the failure case. So, how to find the cause of PCB circuit board failure? Let the engineer share with you: The mechanism of PCB failure must follow basic principles and analysis processes. Firstly, it is necessary to determine the failure location and mode based on the failure phenomenon through information collection, functional testing, electrical performance testing, and simple visual inspection. Next, it is necessary to analyze the failure mechanism, which involves using various physical and chemical methods to analyze the mechanisms that cause PCB failure or defects, such as solder joints, contamination, mechanical damage, moisture stress, medium corrosion, fatigue damage, stress overload, and so on. Then there is the anal

When designing PCB circuit board products, we often care about layout and wiring, which can easily overlook the additional PCB manufacturing costs in the design. Below, let's talk about the factors that affect the sampling price of PCB circuit boards in Shenzhen, in order to avoid increasing costs for customers. 1. Number of wiring layers. The price increases linearly with the number of layers, and the higher the number of layers, the more the price doubles. 2. Through hole. Normally, vias smaller than 0.25mm will be charged by the manufacturer. 3. Plug the hole in the disc. Unless there are strict requirements for signal and layout, try not to use it as it will increase costs. 4. Back drilling. Usually only used for high-speed signals such as backplanes. 5. Line width and line spacing. Usually less than 3.5 mils, additional fees will be charged. 6. Plate (high tg, high-frequency, unconventional) increases procurement cycle and production costs. 7. HDI and blind burial have

Wave soldering is a batch soldering process used for manufacturing PCB circuit boards, mainly used for soldering through hole components. So, what are the issues that need to be paid attention to in the wave soldering process of PCB circuit boards? 1. There is green oil inside the component hole, which leads to poor tin plating inside the hole. The green oil in the hole should not exceed 10% of the hole wall, and the number of holes in the internal green oil should not exceed 5%. 2. Insufficient coating thickness leads to poor tin plating in the hole. 3. The coating thickness on the component hole wall is insufficient, resulting in poor tin plating inside the hole. Usually, the thickness of the hole wall should be greater than 18 μ M. 4. The hole wall is too rough, resulting in poor tin plating or pseudo welding inside the hole. 5. The hole is damp, causing pseudo welding or bubbles. Sealing a PCB before drying or cooling, as well as leaving it for a long time after unpacking,

High frequency circuit wiring is a key and difficult issue in PCB circuit board design. Let Shenzhen PCB manufacturers share with you the high-frequency circuit wiring techniques for PCB design: 1. The less alternating layers of leads between pins in high-frequency circuit devices, the better The so-called "less alternating between lead layers is better" refers to the use of fewer vias (Via) during the component connection process. Reducing the number of vias can significantly improve speed and reduce the possibility of data errors. 2. The shorter the lead between the pins of high-frequency circuit devices, the better The radiation intensity of a signal is proportional to the length of the signal line, and the longer the high-frequency signal lead, the easier it is to couple to components close to it. 3. The less bent the leads between the pins of high-speed electronic devices, the better The lead wire for high-frequency circuit wiring should preferably be fully straight, and i

High frequency circuit wiring should pay attention to the "crosstalk" introduced by signal lines running parallel in close proximity, which refers to the coupling phenomenon between signal lines that are not directly connected. The parameters of the PCB board layer, the spacing between signal lines, the electrical characteristics of the driver and receiver ends, and the termination method of signal lines all have a certain impact on crosstalk. So, what are the measures for reducing high-frequency signal crosstalk in PCB wiring? 1. Inserting a ground wire or ground plane between two lines with severe crosstalk can provide isolation and reduce crosstalk; 2. If parallel distribution cannot be avoided, a large area of "ground" can be arranged on the opposite side of the parallel signal line to significantly reduce interference; 3. If the wiring space permits, the spacing between adjacent signal lines can be increased to reduce the parallel length of signal lines; 4. If parallel run

The EMC issue in PCB design is very important and plays a decisive role in the quality and performance stability of the next PCB circuit board. Below, let the engineer share with you: What factors are related to EMC issues in PCB design? 1. System design: When conducting system level EMC design, it is necessary to first determine the EMI interference source in order to systematically shield, filter, or use other methods to effectively eliminate EMI radiation sources. 2. Structural impact: If the radiation disturbance emission of non-metallic chassis exceeds the standard, measures such as conductive spraying, local shielding cover design, cable shielding treatment, and reasonable grounding treatment should be taken for the chassis. 3. Cable impact: Never use a cable shield as a return path for a signal. 4. The selection of components is related to: Taking varistors as an example: The main characteristic of varistors is their wide operating voltage range, which plays a role i

Aluminum substrate is a metal based copper clad plate with good heat dissipation function, commonly used for making LED lights. Next, let the Shenzhen PCB manufacturer provide you with a detailed explanation of the aluminum substrate production process specifications and difficulties. 1、 Aluminum substrate production process specification: 1. Aluminum substrates are often used in power devices, so copper foil is relatively thick. 2. The aluminum substrate should be protected with a protective film in advance, otherwise chemicals may corrode and cause damage to the appearance. 3. The milling cutters used for producing aluminum substrates have high hardness, and the milling cutter speed is at least two-thirds slower. 4. The processing of aluminum substrates must focus on adding alcohol to the gongs for heat dissipation. 2、 Difficulties in the production process of aluminum substrate: (1) Using mechanical processing of aluminum substrate, there should be no burrs on the edge of

Inquiry Now