+86 755 2794 4155

+86 755 2794 4155  sales@knownpcb.com

sales@knownpcb.com

-

Shenzhen KNOWNPCB Technology Co., Ltd.

+86 755 2794 4155

+86 755 2794 4155  sales@knownpcb.com

sales@knownpcb.com

Have you noticed that now more and more of our lighting is using led lighting.What is LED? Compared to the traditional light bulbs, LEDs have lower power consumption, longer lifetime and higher energy efficiency. In the PCB industry,when we say LED PCB, it refers to the pcb used for LED lighting, if you are looking for a suitable LED PCB for your lighting system, this article may bring you something. WHAT ARE LEDS COMPOSED OF?LED is an initial light-emitting diode that produces light when an electric current passes through. LEDs typically have negative and positive electrodes, which generate light in the visible light region.The LEDS are glued to the PCB by soldering process and have electrical connections for lighting.Since light-emitting diodes dissipate a lot of heat when they are in use, when you are designing LED, the metal core is usually the best choice for LED PCB, it is because that it dissipates heat more faster. Among them, the metal material aluminum is the most widely used

Another reason for this problem is that the composition of the solder wire used throughout the production, processing, and manufacturing process changes, resulting in excessive residue and the need to add pure tin or replace the solder wire. Spot printed laminated glass undergoes changes in the physical state of chemical fiber layers, such as separation between layers. But this type of situation is not due to poor spot welding. The reason is that the base steel plate is too hot, so it is necessary to reduce the heating and soldering wire temperature or increase the driving speed of the base steel plate. In general, the solder wire of the module half hole PCB board appears dark gray, but sometimes there are orange spot welds. The key reason for this problem is that the temperature is too high, and only lowering the temperature of the tin furnace is sufficient. Due to the structure of the PCB itself, it is very easy to cause harm to the module's half hole PCB board when exposed to

The short circuit fault of the module half hole PCB board is one of the common problems that immediately cause the module half hole PCB board to not work. There are many reasons for this type of problem, and everyone will analyze it one by one below. 1) The main reason for PCB short circuit faults is the poor design of the solder pad. In this case, it is possible to change the circular solder pad to an elliptical shape, increase the spacing between points, and avoid short circuit faults. 2) Inappropriate design solutions for PCB component orientation can also lead to short circuit faults on wooden boards and prevent them from working properly. If the foot of a SOIC is parallel to the tin wave, it is very easy to cause a short circuit fault accident. At this time, the orientation of the part can be adjusted appropriately to make it perpendicular to the tin wave. 3) There is also a probability that it can lead to a common fault of PCB short circuit, which is fully automatic softwa

Why do module half hole PCB boards require vacuum packaging bags? Although this issue is small, it is indeed a problem that many circuit board manufacturers attach great importance to. Due to the lack of good sealing performance of the module half hole PCB board, its surface gold deposition, tin spraying, and welding layer positions will be oxidized by air, which poses a threat to welding and is not conducive to production and manufacturing. So, how do you store the module half hole PCB board? A circuit board is not like any other product, it cannot touch gas or water. The module half hole PCB vacuum pump cannot be damaged. When loading, a layer of bubble pad should be placed next to the small box. The bubble pad has good water absorption ability, which has a very good effect on waterproofing. Naturally, waterproof beads are also indispensable. Then classify and label the pollutants. After packing, the small box must be separated from the wall, stored off the ground in a dry and c

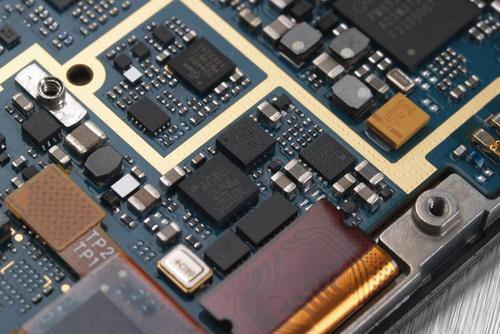

The quality and production efficiency of SMT chip placement processing are crucial for PCB circuit boards. If they are the foundation of PCB circuit boards, then SMT process materials are the bricks and stones of PCB circuit boards, playing a crucial role. Therefore, when designing the SMT process and resumes the production line, it is necessary to select appropriate process materials based on the process flow and requirements. SMT process materials include welding and SMT materials such as solder, solder paste, and adhesive, as well as process materials such as flux, cleaning agent, and heat conversion medium. Next, let's introduce the main functions of assembly process materials. (1) Solder and solder paste Solder is an important structural material in surface assembly processes. Different types of solder are used in different applications to connect the metal surface of the welded object and form solder joints. Reflow soldering uses solder paste, which is a welding material an

The SMT installation rate is very important for PCB companies. It can be said that many people are concerned about the SMT installation rate because it not only affects the processing cost of the production line, but also affects the operating speed of the workshop. Today, the editor will introduce to you the impact of suction nozzles on the SMT installation rate! The suction nozzle is also another important factor affecting the installation rate, which can be caused by both internal and external factors. 1: On the one hand, the internal reason is insufficient vacuum negative pressure. Before removing the parts from the suction nozzle, the mechanical valve on the installation head will automatically switch from blowing to true adsorption, resulting in a certain negative pressure. After absorbing the parts, when the detection value of the negative pressure sensor is within a certain range, the machine is normal, and vice versa, the suction is not good. Generally speaking, the nega

A: Component installation offset mainly refers to the position deviation in X-Y after the component is installed on the PCB. The reasons for this are as follows: (1) Reason for PCB board a: The curvature of the PCB board exceeds the allowable range of the device. The maximum upwarping is 1.2mm, and the maximum downwarping is 0.5mm. b: The height of the support pins is inconsistent, resulting in uneven support of the printed board. c: Poor flatness of workbench support platform d: Circuit board wiring has low accuracy and poor consistency, especially with significant differences between batches. (2) The suction pressure of the mounting nozzle is too low, and it should be above 400mmHG when taking out and mounting. (3) Abnormal blowing pressure during installation. (4) Abnormal or deviation in the amount of adhesive or solder paste applied. This leads to displacement during component installation or welding, resulting in deviation from the original position during high-speed

1: The optical recognition system is a fixed optical camera system. During the rotation process of the installation head, the contour of the components is recognized by the camera for optical imaging. At the same time, measure and record the center position and rotation angle of the components relative to the camera, and transmit them to the transmission control system to compare the XY coordinate position deviation and θ, Angle deviation compensation has the advantages of accuracy and flexibility, and is suitable for various specifications and shapes of components. It has a reflection recognition mode based on device electrodes, and the recognition accuracy is not affected by the size of the nozzle. Components such as SOP, QFP, BGA, PLCC generally use reflection recognition mode. The transmission recognition method is based on the shape of the component, and the recognition accuracy is affected by the size of the suction nozzle. When the shape of the suction nozzle is larger than

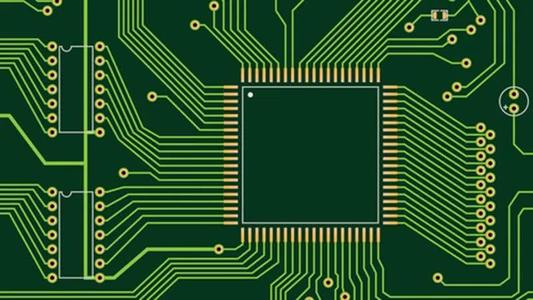

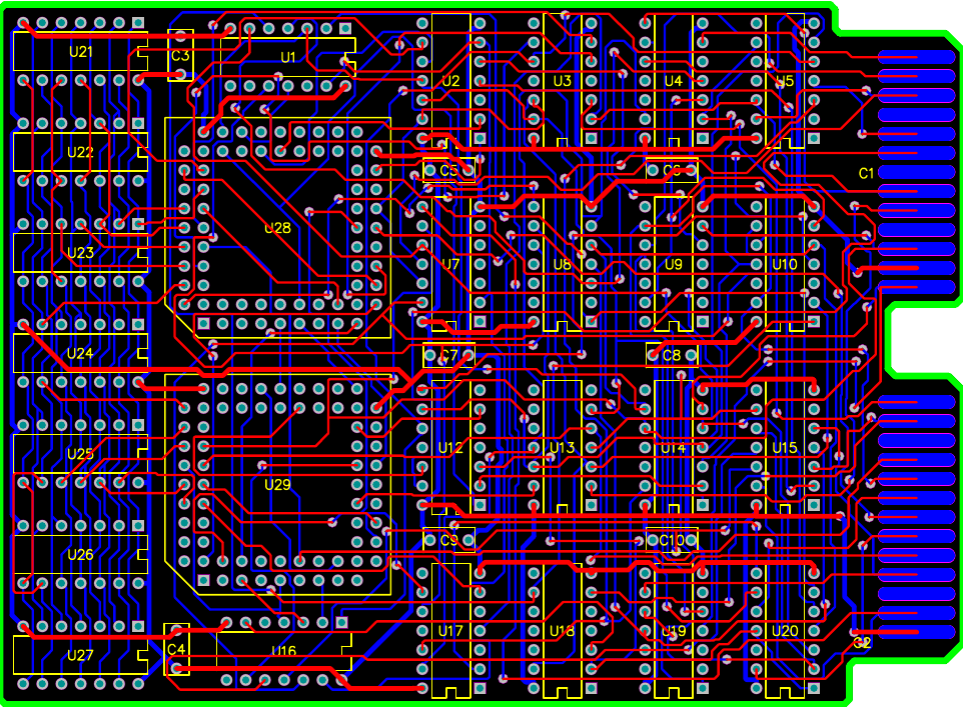

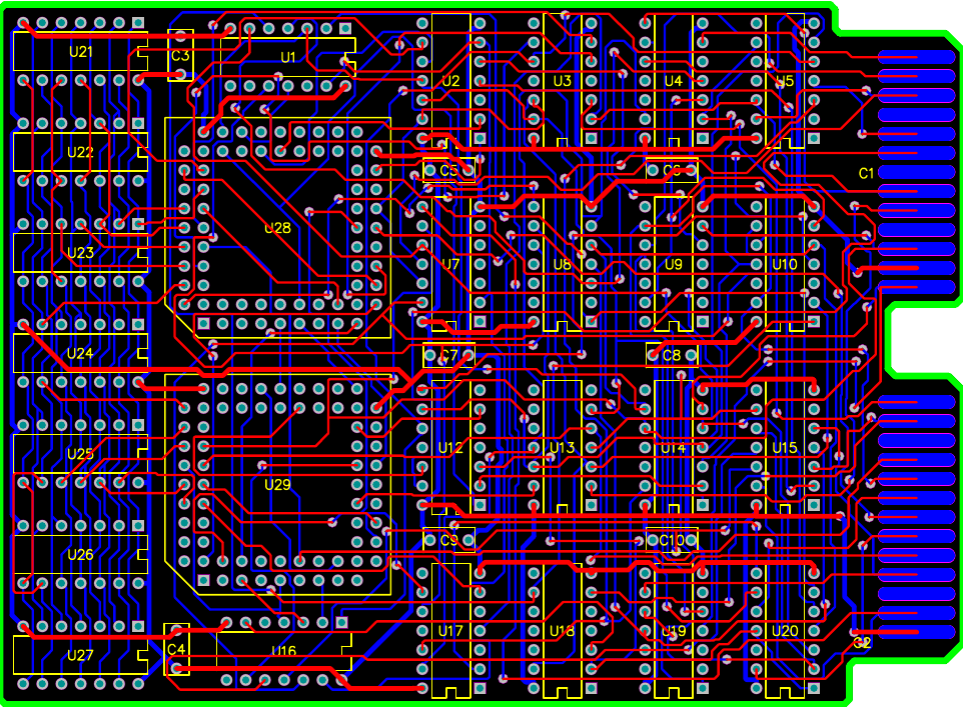

Printed circuit boards (PCBs) are an indispensable part of electronic devices, and their performance and reliability directly affect the operation of the entire system. PCB (Printed Circuit Board), also known as Printed Circuit Board (PCB) in Chinese, is an important electronic component that supports electronic components and serves as a carrier for the electrical interconnection of electronic components. Due to its use of electronic printing technology, it is called a "printed" circuit board. Cabling is a key step in PCB design, which determines the performance and stability of the circuit board. This article will explore the wiring principles and practical techniques of PCB boards to help engineers achieve better results in design. Wiring principles Following the circuit schematic diagram Wiring should strictly follow the circuit schematic to ensure correct wiring connections and prevent short or open circuit problems. During the wiring process, each component in the circuit

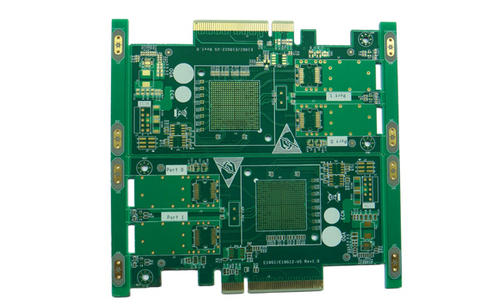

There are many knowledge points about PCB, and it is difficult for one to understand them in a short time, but basic common sense still needs to be learned quickly. So, do you understand the basic knowledge of PCB sampling? 1. PCB measurement unit The unit of measurement for PCBs is usually English units, not metric units. The units of dielectric thickness, conductor length, and width are usually in inches or mils. 1mil=0.001in, 1mil=0.0254mm The thickness of a conductor is measured in ounces (oz, where the mass of a metal conductor refers to the mass of 1 inch of material), Commonly used thickness is 0.5oz=17.5 μ m. 1.0oz=35.0 μ m. 2.0oz=70.0 μ m. 3.0oz=105.0 μ M. 2. Physical characteristics of PCB transmission lines In PCB proofing, the length L and width W of the transmission line are usually set by the PCB layout engineer. The width and spacing of transmission lines are generally not less than 5mil; The thickness H of the transmission line varies depending on the manufac

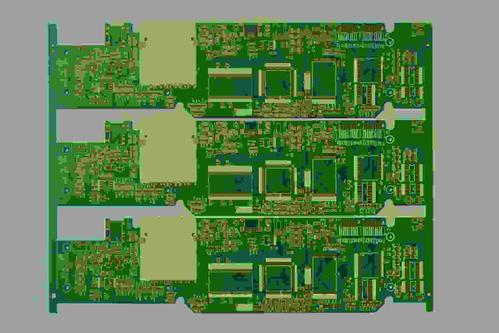

The high degree of customization is the most important characteristic of PCBs. There are significant differences in the usage scenarios, products, performance, materials, areas, and other aspects of PCBs, resulting in significant changes in the types of components used, the thickness of connecting wires, and the density of wiring. This requires PCB companies to have strong customized production capabilities. Although the PCB industry has some common basic processes, the most important thing is to determine different production processes and equipment based on the accuracy requirements of substrate thickness and material, line width and distance, design structure and production scale, as well as other specific requirements specified by customers, resulting in significant differences in production prices. So, do you know what the cost components of PCB circuit boards are? The production process of PCB is relatively complicated, usually involving more than 40 processes such as inner

1. One side adopts red glue technology, and the other side adopts solder paste technology This method is suitable for PCB boards with dense components and different sizes of components on one side. Especially when the gravity of large components is high, there will be detachment phenomenon after reflow soldering, and at this time, the red glue will become more firm when exposed to heat. The process flow is as follows: incoming material inspection -->A-side screen printing solder paste on PCB -->SMT -->AOI or QC inspection -->A-side reflow soldering -->flip board -->B-side screen printing red glue or dot red glue on PCB (note that both dot red glue and dot red glue apply to the middle part of the component, and do not let the red glue contaminate the solder pad, causing the component feet to not solder) -->SMT -->drying -->cleaning -->testing -->repair. It should be noted that the solder paste surface must be welded first before drying the red adhesive surface. Because the drying t

Wave soldering is a batch soldering process used for manufacturing PCBs. The basic equipment used in this process is to move PCB through conveyors in different areas, solder trays used in the welding process, pumps that generate actual waves, and spray and preheating pads for flux. Solder is usually a mixture of metals. Wave soldering is mainly used for welding through hole components. 1. There is green oil inside the component hole, which leads to poor tin plating inside the hole. The green oil in the hole should not exceed 10% of the hole wall, and the number of holes in the internal green oil should not exceed 5%. 2. Insufficient coating thickness leads to poor tin plating in the hole. 3. The coating thickness on the component hole wall is insufficient, resulting in poor tin plating inside the hole. For example, copper thickness, tin thickness, gold thickness, etc. Usually, the thickness of the hole wall should be greater than 18 μ M. 4. The hole wall is too rough, resulting

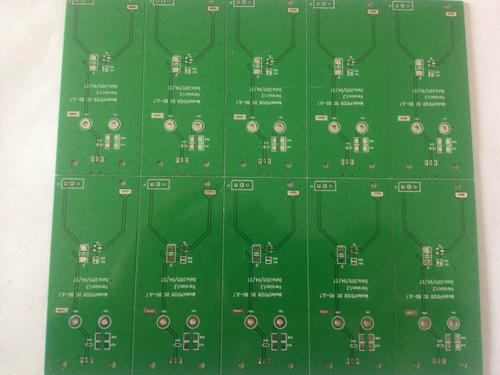

What matters do customers need to explain to the PCB sampling manufacturer when submitting PCB sampling orders? Next, let the editor tell you. 1. Material: Describe the manufacturing material used for PCB proofing, the most common being FR4, which is mainly epoxy resin peeled fiber cloth board. 2. Board layer: Indicate the number of layers made. 3. Resistance welding color: There are many colors available, which can be selected according to your own requirements, usually green. 4. Silk screen color: The font and border color of the silk screen on the PCB board are generally selected as white. 5. Copper thickness: The thickness of copper is generally scientifically calculated based on the current of the PCB circuit, and generally the thicker the better, but the cost will be higher. 6. Is the through-hole covered with solder mask: solder mask is used to insulate the through-hole, otherwise it will cause the through-hole to become uninsulated. 7. Surface coating: with tin spray

There are many factors that contribute to the price of PCB samples, and it is difficult for new salespeople to quote a standardized price without understanding the factors that contribute to PCB price composition. So, what are the components of PCB quotation? 1. Urgent or not For customers with tight delivery requirements, they can apply for expedited order service. For general single and double sided boards that require 12 hours of expedited delivery, PCB sampling manufacturers may charge an expedited fee of approximately 800 yuan. 2. Invoice fees Some customers' companies have very formal financial procedures, so they need to provide invoices for every PCB procurement project, and invoicing is subject to taxation. Therefore, PCB sampling manufacturers generally add this invoice tax to the PCB sampling price. 3. Express delivery fees Generally, customers with long-term cooperation and relatively close geographical locations will be delivered free of charge by drivers appoint

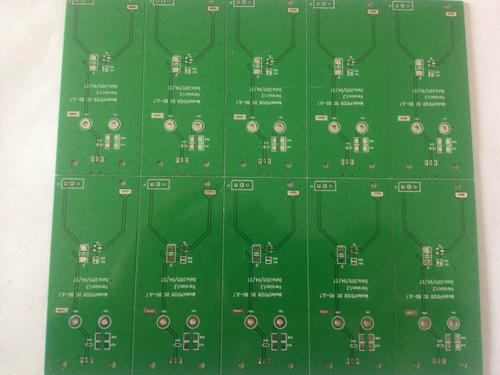

PCB sampling refers to the production of a small quantity of PCB samples for functional debugging before starting mass production of circuit boards; After the functional debugging is completed, subsequent batch production can be carried out, which can avoid production risks and reduce losses caused by product errors. There are two methods for PCB sampling, namely formal PCB factory sampling and professional sample company sampling. So, what are the differences between the two types of sampling? Next, let the editor tell you. 1. The purpose of regular PCB factory sampling is to have bulk orders and hope that customers can have a return order; Professional sample companies themselves only produce samples or small batches, and if there are large orders, they generally cannot do so. 2. In terms of quality assurance, it is certain that regular PCB factories do better than professional sample companies. Professional sample companies usually charge for samples upon delivery, do not eve

High frequency circuit board refers to a special type of circuit board with high electromagnetic frequency, used for PCBs in the fields of high frequency (frequency greater than 300MHz or wavelength less than 1 meter) and microwave (frequency greater than 3GHz or wavelength less than 0.1 meter). It is a circuit board produced using ordinary rigid circuit board manufacturing methods or special processing methods on microwave substrate copper clad board. Generally speaking, high-frequency boards can be defined as circuit boards with frequencies above 1GHz. High frequency circuit boards are one of the high difficulty boards, so what are the requirements for making high frequency circuit boards? 1、 Drilling 1. The drilling feed speed should be slow, with a speed of 180/S. A new drilling nozzle should be used, with aluminum plates placed on top and bottom. It is best to drill with a single PNL, and the hole should not be exposed to water; 2. The ground plate copper sinking circuit i

The product quality of circuit boards is produced, not inspected. Only by strictly following the production process and operation instructions at every stage of the production process can the quality of the products be guaranteed. Therefore, in the production of PCB circuit board products, circuit board manufacturers must do the following 8 points: Firstly, establishing the awareness that quality is the lifeblood of an enterprise To recognize: poor product quality; Products have no market, products have no market, and enterprises lose their source of profit. Of course, for companies, even if the product market is good, they should "be prepared for danger", improve product quality, and create a better corporate reputation. Secondly, establish a customer awareness of quality Everything is customer-centric, treating oneself as the customer, the operator of the next process, and the consumer of the product. If you cut corners in your work, it will harm your personal interests. Thi

What problems will you encounter when designing circuit board samples? The following is a summary of ten common problems encountered in PCB sample design. 1、 Overlap of pads Overlapping solder pads means overlapping holes. During the drilling process, multiple drilling at one location can cause damage to the holes and result in scrapping. 2、 Graphic layer abuse Specific performance: Some useless connections were made on some graphics layers, and originally a four layer board was designed with circuits above five layers, which caused misunderstandings; Violation of conventional design, such as component surface design at the Bottom layer and welding surface design at the Top, causing inconvenience, etc. Therefore, maintaining the integrity and clarity of the graphic layer during design. 3、 Character shuffling Specifically, the character cover solder pad SMD solder pad brings inconvenience to the on/off testing of circuit boards and the welding of components; Also, the characte

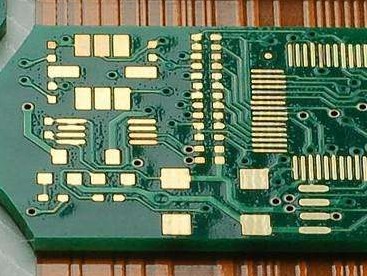

Aluminum substrate is a metal based copper clad plate with good heat dissipation function, commonly used for making LED lights. Let's now understand the difficulties and production specifications of the aluminum substrate production process. 1. Aluminum substrates are often used in power devices with high power density, so copper foil is relatively thick. If copper foil above 3oz is used, the etching process requires engineering design line width compensation. 2. The aluminum substrate surface of the aluminum substrate is protected with a protective film in advance during PCB processing, otherwise some chemicals may corrode the aluminum substrate surface and cause appearance damage. 3. The milling cutter used in the production of fiberglass board has a relatively low hardness and fast milling speed; The milling cutters used in the production of aluminum substrates have high hardness, and the milling cutter speed is at least two-thirds slower. 4. To produce fiberglass panels, on

l. Areas with unreasonable design are most prone to malfunctions What are the unreasonable design aspects of industrial circuit boards? Firstly, there is a heat dissipation issue, as many circuit boards are damaged due to poor heat dissipation design; Secondly, the copper foil wire of the printed circuit board is used. The copper foil of the power supply wire of the circuit board with poor quality is very thin, which is easily burnt off due to overcurrent, making the motherboard unable to work. 2. Frequently used areas are prone to malfunctions For example, the drive motor of industrial circuit boards, rotating shafts, switch tubes of switching power supplies, commonly used buttons on operation panels, etc. 3. Components with heavy loads, high power, and high operating voltage are most likely to malfunction The power supply, drive circuit, power control device, operational amplifier, etc. of industrial circuit boards are the most vulnerable to damage. These components are gene

Inquiry Now