+86 755 2794 4155

+86 755 2794 4155  sales@knownpcb.com

sales@knownpcb.com

-

Shenzhen KNOWNPCB Technology Co., Ltd.

+86 755 2794 4155

+86 755 2794 4155  sales@knownpcb.com

sales@knownpcb.com

Have you noticed that now more and more of our lighting is using led lighting.What is LED? Compared to the traditional light bulbs, LEDs have lower power consumption, longer lifetime and higher energy efficiency. In the PCB industry,when we say LED PCB, it refers to the pcb used for LED lighting, if you are looking for a suitable LED PCB for your lighting system, this article may bring you something. WHAT ARE LEDS COMPOSED OF?LED is an initial light-emitting diode that produces light when an electric current passes through. LEDs typically have negative and positive electrodes, which generate light in the visible light region.The LEDS are glued to the PCB by soldering process and have electrical connections for lighting.Since light-emitting diodes dissipate a lot of heat when they are in use, when you are designing LED, the metal core is usually the best choice for LED PCB, it is because that it dissipates heat more faster. Among them, the metal material aluminum is the most widely used

The volume of electronic products is becoming increasingly thin and short, and directly stacking holes on through blind holes is a design method to achieve high-density interconnection. To achieve good hole stacking, the first step is to ensure the flatness of the hole bottom. There are several typical methods for making flat hole surfaces, and electroplating hole filling process is one of the representative ones. The electroplating hole filling process can not only reduce the necessity of additional process development, but also be compatible with current process equipment, which is conducive to achieving good reliability. So, what factors affect the PCB electroplating hole filling process? In PCB sampling, the influence of substrate on electroplating hole filling cannot be ignored, generally including factors such as dielectric layer material, hole shape, thickness to diameter ratio, and chemical copper coating. (1) Medium layer material. The material of the dielectric layer ha

In PCB sampling, nickel is used as a substrate coating for precious and base metals. For some surfaces with heavy load wear, using nickel as the gold substrate coating can greatly improve wear resistance. When used as a barrier layer, nickel can effectively prevent the diffusion between copper and other metals. Next, CITIC Huawei will explain the causes and solutions of PCB nickel plating process faults: 1、 Ma Keng: Ma Keng is the result of organic pollution; If the stirring is poor, bubbles cannot be expelled and pits will form. Large pits usually indicate oil contamination, and wetting agents can be used to reduce their impact. Small pits are called pinholes, which can be caused by poor treatment, metal impurities, low boric acid content, and low plating temperature. Bath maintenance and process control are key, and anti pinhole agents should be used as process stabilizers to supplement. 2、 Roughness and burrs: Roughness indicates that the solution is dirty, which can be correc

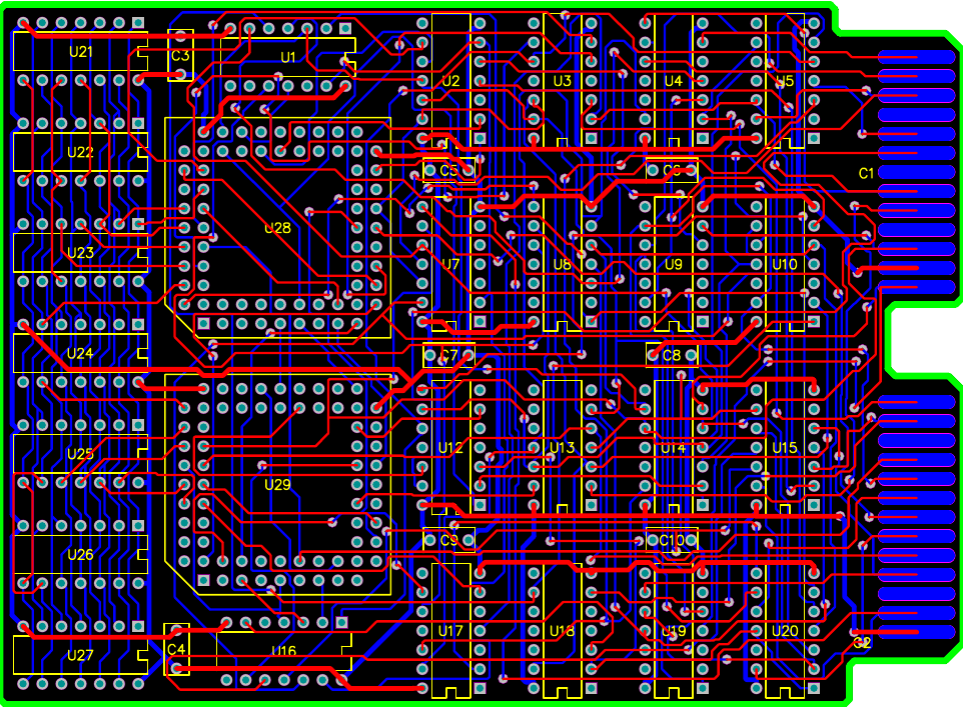

When designing high altitude circuit boards, multi-layer circuit boards are usually used instead of single-layer and double-layer circuit boards. Why is this? Today brings you the reason for using multi-layer boards for high-speed circuit boards! Let's take a look together! Multi layer boards have many characteristics that are not found in single or double layer boards, and it is precisely because of these characteristics that high-speed circuit board designs use multi layer boards instead of other circuit boards. The following is a summary of the characteristics of multi-layer boards! 1. The power supply is very stable; 2. The circuit impedance is significantly reduced; 3. The wiring length is significantly shortened. In addition, from a cost perspective, although the cost of multi-layer circuit boards is higher than that of single-layer circuit boards, the cost difference between multi-layer circuit boards and single-layer circuit boards is not as high as expected when consider

High frequency board refers to a special circuit board with high electromagnetic frequency. Generally speaking, high frequency can be defined as a frequency above 1GHz. The application range of high-frequency circuit boards is very wide, and there are strict requirements in design and manufacturing. So, what are the specific requirements for the production of high-frequency PCB circuit boards? 1. The corner of the transmission line should adopt a 45 ° angle to reduce return loss; 2. The use of high-performance dielectric circuit boards with strictly controlled dielectric constant values according to the number of layers is conducive to effective simulation calculation of the electromagnetic field between insulation materials and adjacent wiring. 3. Produce according to the design specifications for high-precision etching of circuit boards. The total error of the specified line width is+/-0.0007 inches, and overall management of the wiring (wire) geometry and coating surface is c

The size of HDI is limited by the capacity of electronic processing production line equipment, therefore, appropriate HDI size should be considered in product system design. (1) The maximum HDI size that SMT devices can mount comes from the standard size of HDI sheets, most of which are 20 " × 24 ″, i.e. 508mm × 610mm (rail width) (2) The recommended size is a relatively suitable size for each equipment on the SMT production line, which is conducive to maximizing the production efficiency of each equipment and eliminating equipment bottlenecks. (3) For small-sized HDI, it should be designed as a combination to improve the production efficiency of the entire production line. Design Requirements (1) In general, the maximum size of HDI should be limited to 460mm × Within the range of 610mm. (2) The recommended size range is (200-250) mm × (250~350) mm, the aspect ratio should be

What is HDI (High Density Interconnects) wiring? HDI (High Density Interconnects) wiring refers to the use of the latest design strategies and manufacturing technologies to achieve more dense designs without affecting circuit functionality. In other words, HDI involves the use of multiple wiring layers, smaller wiring, vias, solder pads, and thinner substrates to install complex and usually high-speed circuits within previously impossible footprint areas. With the development of manufacturing technology, HDI wiring has begun to be seen in many designs, such as motherboards, graphics controllers, smartphones, and other space limited devices. If implemented properly, HDI wiring can not only greatly reduce design space, but also reduce EMI issues on PCBs. Reducing costs is an important goal for the company, and HDI cabling can precisely achieve this. It is important to understand that HDI wiring and micro vias are more complex than typical multi-layer wiring strategies. We may have de

1、 Raw materials The raw materials for PCB sinking gold plates mainly include substrates, electroplating solutions, and chemicals. Among them, the substrate is the main component of the PCB gold plate, and the material and quality of the substrate directly affect the quality of the PCB gold plate. If the material of the substrate is impure or of poor quality, it is easy to cause carbon elements in the PCB gold plate to exceed the standard. 2、 Production process The production process of PCB sinking plates includes multiple processes such as chemical gold plating, electroplated gold plating, and nickel plating. In these links, if the operation is improper or the process is not perfect, it can lead to excessive carbon content in PCB gold plating plates. For example, in the chemical gold plating process, if the temperature, pH value, concentration and other parameters of the plating solution are not suitable, it can lead to excessive carbon content. 3、 Equipment and facilities Th

1、 Design phase 1. Preliminary design. The first step in PCB design is to determine the circuit diagram, select components and connect circuits based on the functional requirements of the product. 2. Perform PCB layout. Layout design is the first step after completing circuit design, which requires determining the approximate size and shape of the PCB board, as well as the approximate positions of various components on the board. 3. Wiring design. Designers need to design the connection method and path of the circuit at each layer of the PCB, which is called wiring design. 2、 Material preparation stage 1. Select the substrate. Before starting the production of PCB multilayer boards, it is necessary to choose a suitable substrate, usually fiberglass board. 2. Make copper foil. Copper foil is the most important conductive material in PCB, and thickness selection and production should be based on the design requirements of the PCB. 3. Produce photoresist film. Photoetching film

1、 Material selection The production of high-frequency and high-speed printed circuit boards requires the selection of materials with good electrical properties. However, there are many types of materials on the market, and how to choose the appropriate materials has become a challenge. Firstly, it is necessary to consider the dielectric constant and loss factor of the material to ensure the stability and low loss of signal transmission. Secondly, it is also necessary to consider the thermal expansion coefficient and thermal conductivity of the material to avoid size changes and heat accumulation caused by temperature changes. In addition, the machinability and cost of materials also need to be considered. 2、 Design specifications The design of high-frequency and high-speed printed circuit boards needs to comply with certain standards. Firstly, it is necessary to layout the circuit reasonably to reduce the transmission path and interference of the signal. Secondly, it is necessa

1、 Design considerations When designing multi-layer circuit boards, the following points need to be noted: 1. Determine the number of circuit board layers and interlayer connection methods, reasonably plan the layout of signal and power layers, and avoid signal interference and power noise. 2. Reasonably arrange the size and layout of the circuit board to ensure its manufacturability and assemblability. 3. Choose appropriate line width and spacing to avoid signal crosstalk and current overload. Multilayer circuit board 2、 Material selection considerations When selecting materials for multi-layer circuit boards, the following points need to be noted: 1. Choose high-quality substrate materials, such as FR-4 or high-frequency materials, to ensure the stability and reliability of the circuit board. 2. Choose the appropriate thickness of copper foil, based on current and signal requirements, to avoid overload and signal distortion. 3. Select appropriate interlayer dielectric m

1. Process flow The main process flow of testing and quality inspection includes AOI testing, X-ray testing, antioxidant treatment, and aging treatment, each step of which needs to be strictly executed according to the process. Due to the crucial importance of testing and quality inspection in ensuring product quality and performance, it is necessary to pay more attention to the control of technical points. 2. Technical points In the process of testing and quality inspection, there are several technical points that need special attention: (1) Requirements for AOI testing. In the process of AOI detection, attention should be paid to the hardware and software requirements to ensure the effectiveness and accuracy of the detection. (2) Technical requirements for X-ray detection. In the process of X-ray detection, attention should be paid to the parameters and equipment requirements to ensure the effectiveness and accuracy of the detection. (3) Requirements for antioxidant treatme

Firstly, we need to consider the specific application scenarios and requirements of PCBs. If a PCB is to be used for high-frequency circuits or high-speed signal transmission, a thinner ink thickness may be more suitable as it can reduce signal transmission loss and reflection. Additionally, if the PCB is to be used in high-temperature environments or circuits with higher power, a thicker ink thickness may be more suitable as it can provide better insulation and heat dissipation performance. Secondly, we also need to consider PCB manufacturing process and cost factors. A thinner ink thickness may require higher manufacturing accuracy and more complex process flow, which may increase manufacturing costs. A thicker ink thickness may be easier to achieve, but it may increase the weight and size of the PCB. Therefore, when selecting ink thickness, it is necessary to comprehensively consider manufacturing process and cost factors. Finally, we also need to consider the reliability and

1. Process flow The main process of PCB board production includes graphic design, circuit layout, copper foil coverage, photolithography, etching, drilling, metallization, tin spraying, and organic copper clad board. Each step needs to be strictly executed according to the process. Due to the crucial role played by PCB board production throughout the entire process, great attention should be paid to all production processes. 2. Technical points In the process of PCB board production, there are several technical points that need special attention: (1) Circuit layout. Circuit layout is the foundation of the entire circuit design and one of the key factors determining circuit performance. For high-frequency circuits, attention should be paid to impedance matching and signal interference during the circuit layout process. (2) Photolithography photography. Photolithography refers to the process of amplifying a graphic circuit onto a PCB board through a certain method for comprehens

1. Process flow The main process flow of SMT mounting includes printing, mounting, and soldering, and each step needs to be strictly executed according to the process. Due to the significant impact of SMT mounting on circuit stability and reliability, more attention needs to be paid to quality control and technical difficulties in the production process. 2. Technical points In the process of SMT mounting, there are several technical points that need special attention: (1) Selection and use of glue. During the installation process, it is necessary to select appropriate glue to ensure that the components can be pasted onto the PCB board, and also pay attention to the amount of glue used to avoid affecting the heat dissipation of the components. (2) Selection and use of solder paste. During the installation process, it is necessary to select appropriate solder paste to ensure welding quality, while also paying attention to the amount of solder paste used to avoid affecting the we

1. Process flow The main process flow of DIP plugins includes insertion, welding, and cutting, each step of which needs to be strictly executed according to the process. Due to the use of DIP plugins in many circuit boards, it is also necessary to pay more attention to quality control and technical difficulties in the production process. 2. Technical points In the process flow of DIP plugins, there are several technical points that need special attention: (1) The depth of pin insertion. During the insertion process, it is necessary to pay attention to the depth of insertion to ensure the stability of the plugin and the reliability of the connection. (2) Control of welding temperature and time. During the welding process, it is necessary to strictly control the welding temperature and time to ensure the quality and consistency of the welding. (3) Key technical points for cutting. During the cutting process, it is necessary to pay attention to the cutting angle and force to ens

Usually, when the board is relatively dense, we use vias of the size of 8/16 ± 2mil (8/14, 8/16, 8/18 can be used). When the board is relatively open, we can choose vias of the size of 12/24 ± 2mil (12/22, 12/24, 12/26 can be used). If the device density of the board is between the two, vias of the size of 10/20 ± 2mil (10/18, 10/20, 10/22 can be used). From the perspective of economic benefits, the larger the through-hole, the lower the cost. Therefore, if we want to control the cost of the board, we should try to set the through-hole as large as possible while meeting our design requirements. Of course, in HDI boards, we usually need to use blind buried holes. Usually, the size range of our blind holes can be set to 4/10 ± 2, which is usually enough to be punched on the solder pad. However, it should be noted that they should not be punched on the center of the solder pad, usually on the edge of the solder pad, which will improve the process treatment. So, is it better for our

As is well known, impedance control is the most fundamental principle in our high-speed design. At present, conventional board factories control the impedance to an error of 10%, and many friends may have questions, why is it 10%? In theory, the smaller the error, the better, so why not further increase the conventional control capability to 8%, or even 5%? Ideals may be beautiful, but reality is inevitably cruel. There are many factors that affect the impedance of PCB wiring, mainly including the width and thickness of the copper wire, the dielectric constant of the medium, the thickness of the medium, and the thickness of the solder mask. Therefore, in order to minimize the impedance error, it is necessary to control the errors of various factors mentioned above very well during the PCB processing process, in order to ultimately achieve a small impedance error. But looking at the PCB processing process step by step, you will find that almost every process produces errors in the

Accuracy and consistency: 5G products have increased the data signal transmission rate from 25Gbps to 56Gbps, and have put forward stricter requirements for product impedance, loss, etc. The product impedance requirement has been increased from 10% to 5%, and the line width tolerance has been increased from 20% to 10%. The impact of line flatness on the signal is also significant. From the perspective of the influencing factors of impedance control, the size of impedance tolerance is influenced by the dielectric thickness tolerance, copper thickness tolerance, and current control accuracy. As shown in the following figure, the inner layer impedance tolerance has been reduced from 10% to 5%, the dielectric thickness tolerance should be controlled at ± 7%, the copper thickness tolerance should be controlled at ± 3%, the line width tolerance should be controlled at ± 8%, and the outer layer impedance should also be controlled. This is closely related to sheet metal, PCB engineering d

Blind hole embedding: The functionality of 5G products has been improved, and the demand for high-density PCB circuit boards has increased. There is an increasing demand for multi-stage HDI products and even products that are interconnected in any order. Currently, most PCB factories have a trend towards mature 1-3 level HDI, but higher level blind hole embedding capabilities need to be improved Stub: The short pile effect of 112G products cannot be ignored, and the back drilling stubs have put forward stricter requirements, and ostub will be the trend Copper embedding: Heat dissipation requirements for 5G communication high-frequency high-power devices. Copper blocks are embedded inside the PCB to enhance its heat dissipation capability

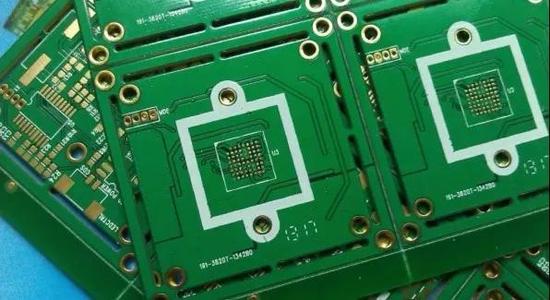

Through hole: A through hole is a hole that passes from one side of a circuit board to the other. They can completely penetrate the entire circuit board and can be soldered through pins, sockets, or other components. Through holes are usually used to connect circuits at different levels, providing electrical connections and mechanical support. Blind via: A blind hole is a hole that only enters the circuit board from one side and does not penetrate the entire board thickness. They are used to connect circuits between surface and internal layers. Blind holes can be welded to components through surface assembly technology, but cannot be connected to the other side of the circuit board through through-holes. Buried via: A buried hole is a hole completely located inside a circuit board, which neither enters or exits from one side nor penetrates the entire board thickness. Buried holes are used to connect circuits between internal layers without affecting the external surface. Buried h

Inquiry Now