+86 755 2794 4155

+86 755 2794 4155  sales@knownpcb.com

sales@knownpcb.com

-

Shenzhen KNOWNPCB Technology Co., Ltd.

+86 755 2794 4155

+86 755 2794 4155  sales@knownpcb.com

sales@knownpcb.com

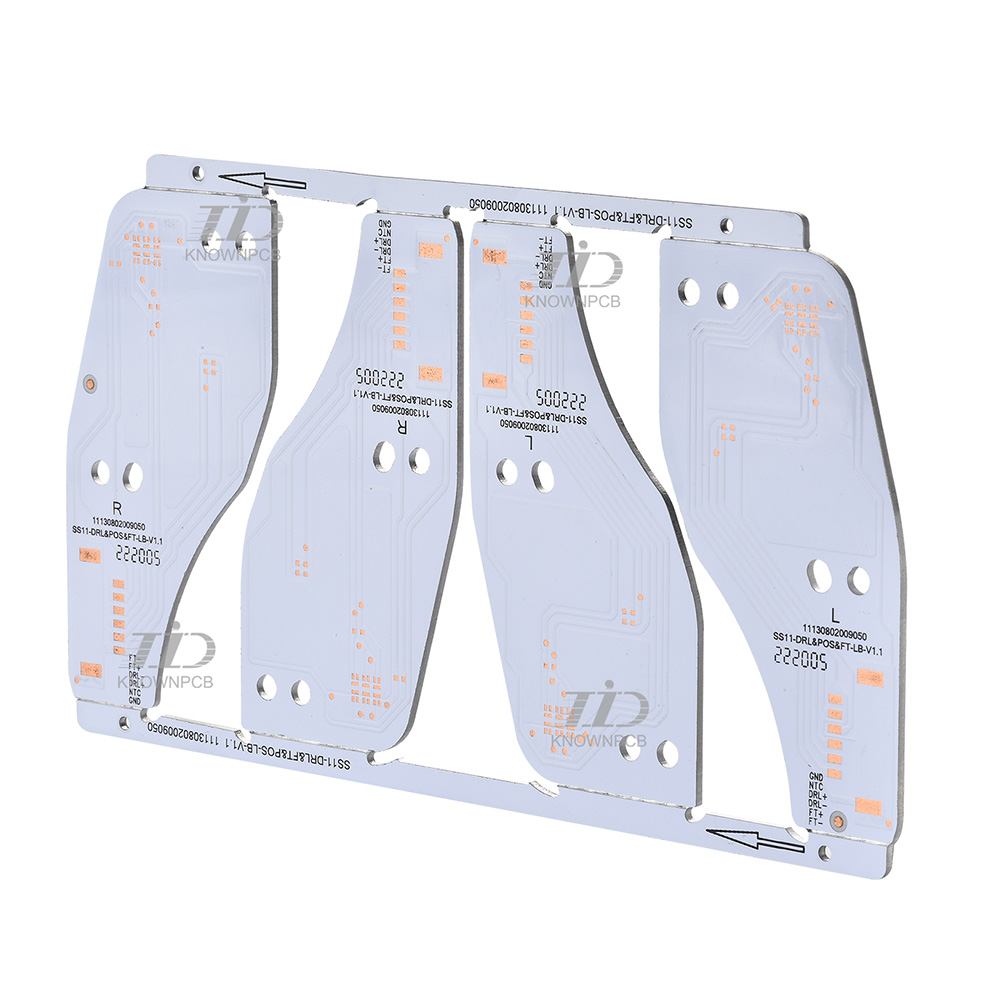

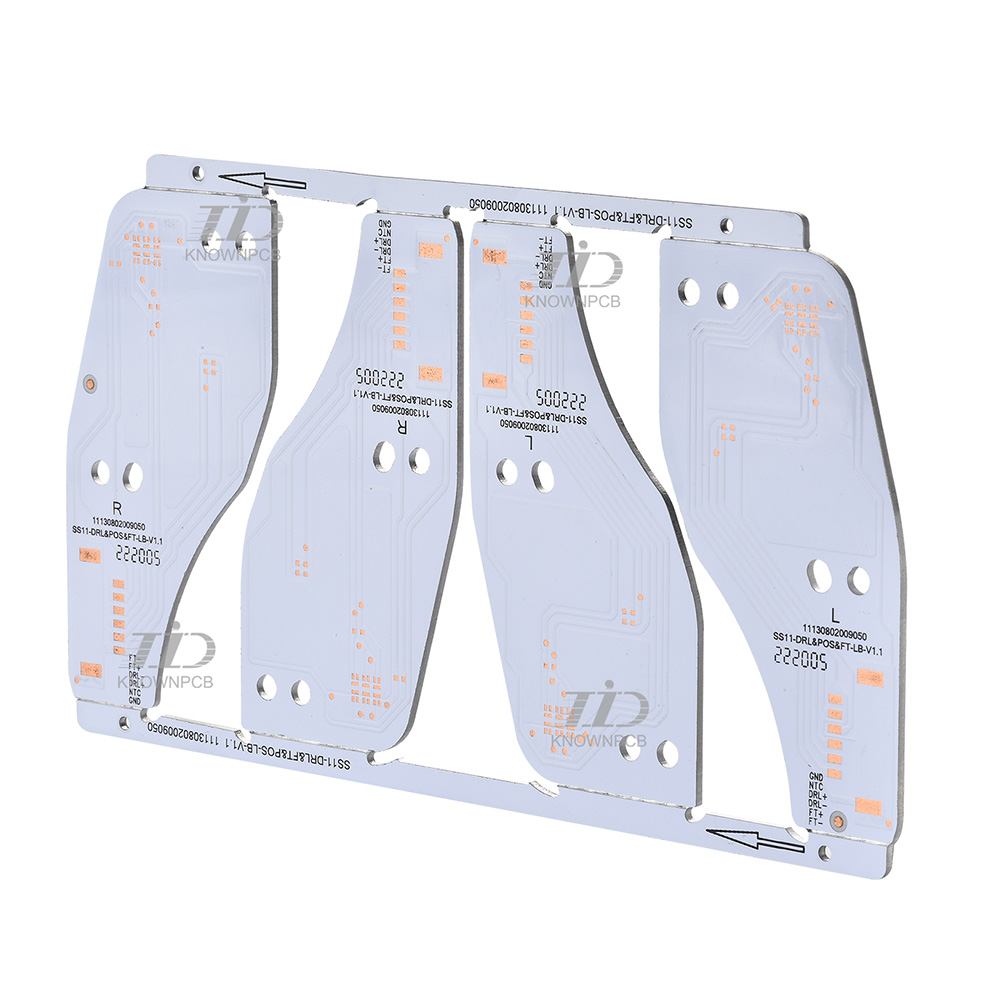

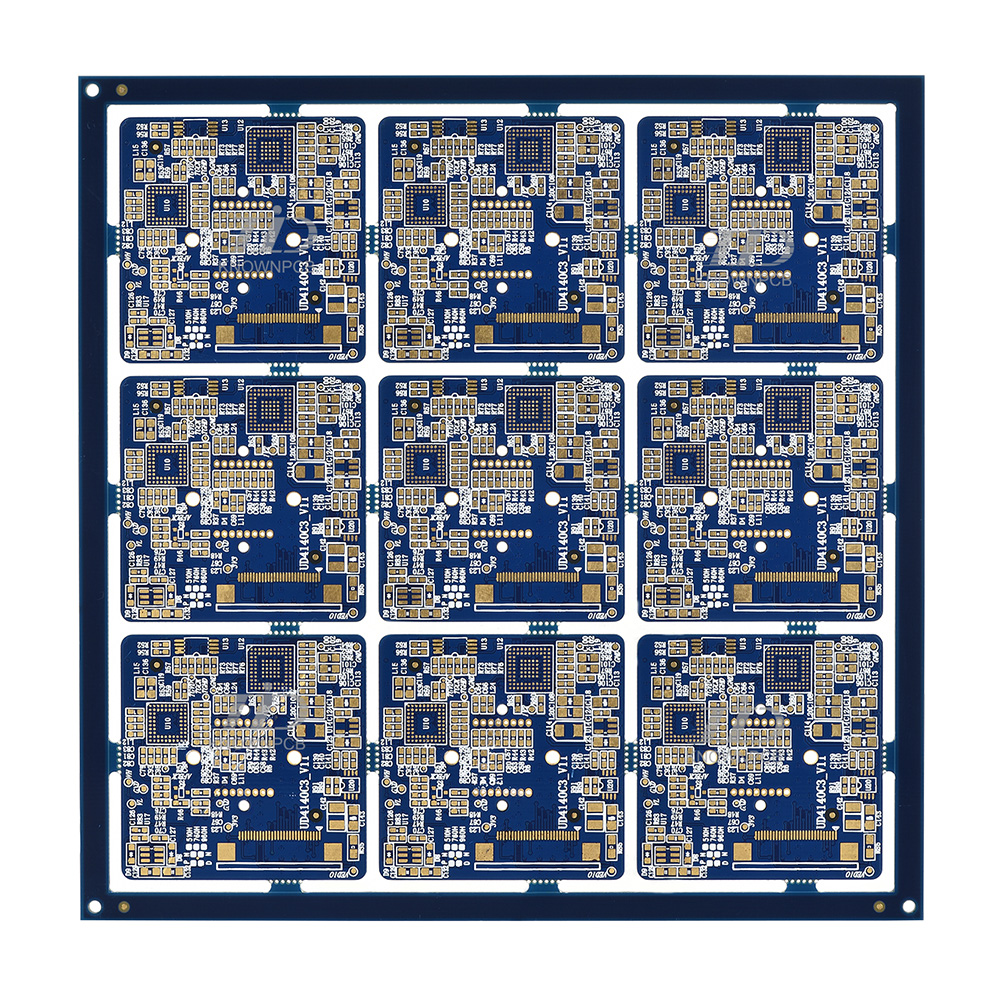

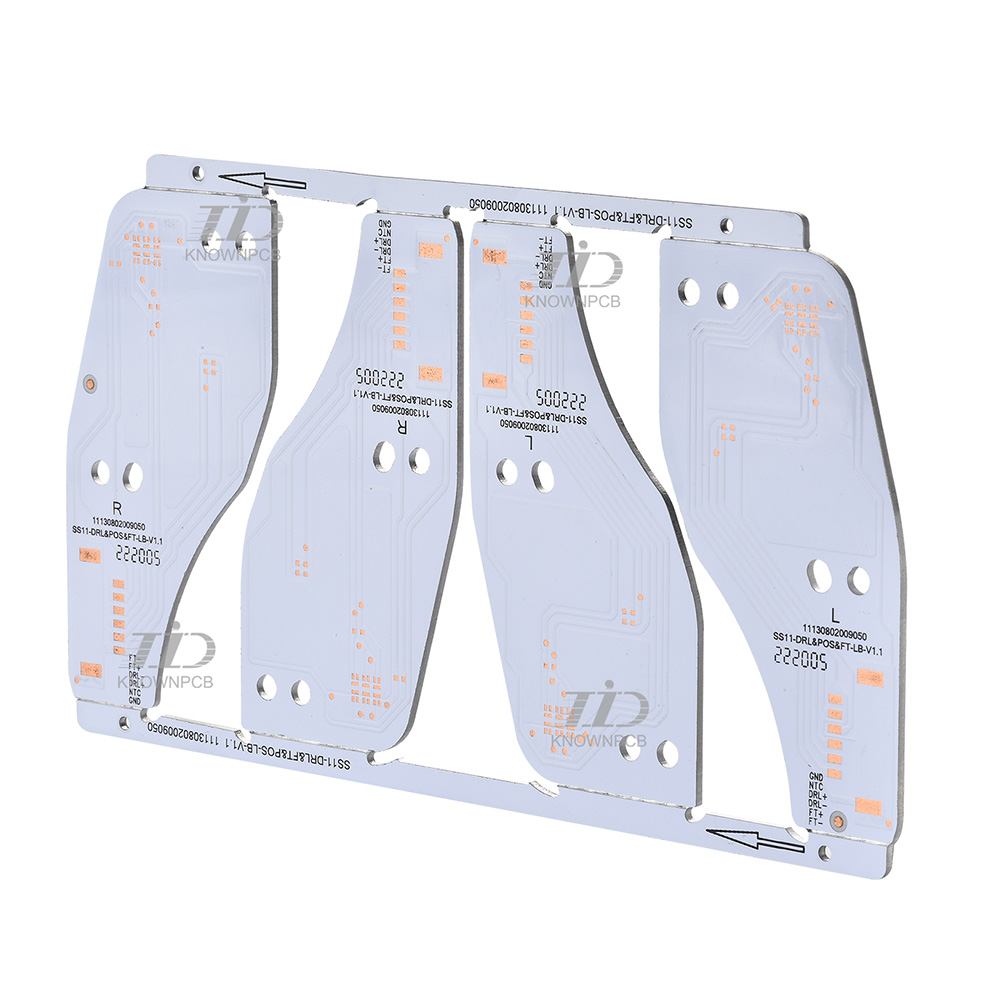

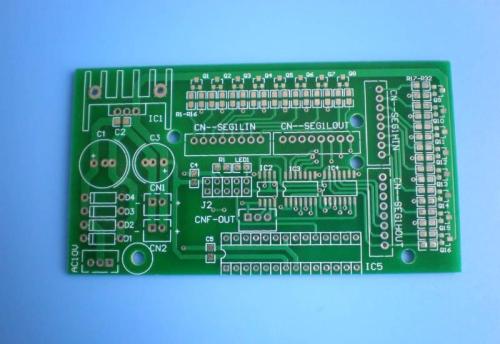

Have you noticed that now more and more of our lighting is using led lighting.What is LED? Compared to the traditional light bulbs, LEDs have lower power consumption, longer lifetime and higher energy efficiency. In the PCB industry,when we say LED PCB, it refers to the pcb used for LED lighting, if you are looking for a suitable LED PCB for your lighting system, this article may bring you something. WHAT ARE LEDS COMPOSED OF?LED is an initial light-emitting diode that produces light when an electric current passes through. LEDs typically have negative and positive electrodes, which generate light in the visible light region.The LEDS are glued to the PCB by soldering process and have electrical connections for lighting.Since light-emitting diodes dissipate a lot of heat when they are in use, when you are designing LED, the metal core is usually the best choice for LED PCB, it is because that it dissipates heat more faster. Among them, the metal material aluminum is the most widely used

Firstly, one of the difficulties in designing and manufacturing high-frequency high-speed boards is ensuring signal integrity. Due to the transmission characteristics of high-frequency signals, the requirements for signal integrity are very high. Once the signal experiences attenuation, interference, or distortion, it will lead to a decrease in system performance or even malfunction. The key to solving the problem of signal integrity is to choose materials, wiring, and grounding methods reasonably, and conduct strict signal integrity simulation and testing. Secondly, the design and production of high-frequency high-speed boards also face challenges in terms of high-frequency characteristics and electromagnetic compatibility. In the transmission of high-frequency and high-speed signals, electromagnetic wave radiation and interference will become a serious problem. In order to improve electromagnetic compatibility, it is necessary to design and layout devices, pins, and ground wir

Firstly, a challenge in the design of switch PCB circuit boards is the issue of signal interference. On PCB boards, the generation and transmission of high-speed signals can generate a significant amount of electromagnetic radiation and mutual inductance. And these radiation and mutual inductance can interfere with other signals, leading to a decrease in communication signal quality. To solve this problem, we can adopt the following strategies: first, reasonably plan the routing of signal and power lines, and minimize the possibility of crossing each other; Secondly, reasonable layout and use of shielding covers and other measures to reduce the propagation of signal interference; Finally, design the grounding wire and shielding ground reasonably to improve the continuity and shielding effect of the grounding wire. Another difficulty in the design of switch PCB circuit boards is the transmission of high-speed signals. Due to the high frequency of high-speed signals in switches, p

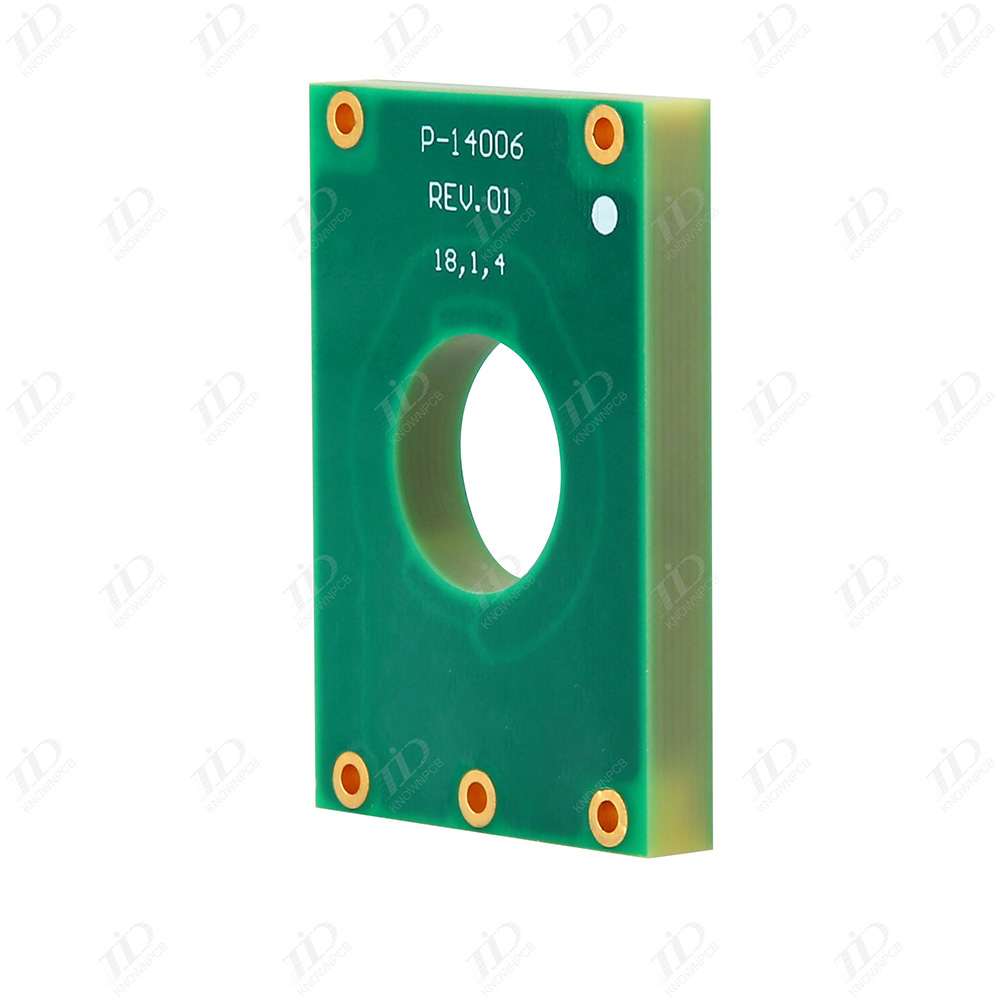

In the design and manufacturing process of PCB circuit boards, step holes are a common and important component. It plays a crucial role in the connection between electronic devices and circuit boards, so understanding the design and manufacturing principles of step holes is one of the essential skills for every electronic engineer and PCB designer. Firstly, let's introduce the basic concepts and functions of step holes. Step holes are holes with different diameters that serve as connections between electronic devices and soldering pins on PCB boards. It is usually composed of two or more cylindrical holes, forming a progressive structure layer by layer, which can effectively bear the stress during welding and connection processes and improve the reliability of the connection. When making step holes, it is first necessary to carry out appropriate design. The design includes selecting appropriate aperture and spacing, as well as determining parameters such as plate thickness and

Firstly, the production of PCB boards usually starts with design. The designer conducts detailed design work based on the functional requirements of the smartphone, combined with electronic schematic and layout diagrams. Designers need to consider various factors such as signal transmission, power supply, and circuit isolation to ensure the stable and reliable performance of the PCB board. After the design is completed, the next step is the sampling stage of the PCB board. The production of PCB boards requires the use of electrical discharge machining technology, photolithography technology, chemical etching technology, and electroplating technology. Firstly, based on the designed CAD drawings, the pattern is transferred to a fiberglass board covered with copper foil using photolithography technology. Next, through chemical etching technology, unnecessary copper foil is etched away, leaving the required circuit; Then, using electroplating technology to increase the conductivity

1、 V-shaped cutting and splitting process The V-shaped cutting and splitting process uses a V-shaped cutting tool to cut V-shaped grooves on both sides of the circuit board, and then break the circuit board to separate it. This process is suitable for most general board splitting needs, with simple operation and low cost. However, its disadvantage is that it is prone to cutting burrs and uneven board edges, making it suitable for circuit boards with no connectors or components on the edges. 2、 Machine milling and cutting process The machine milling and cutting process involves using a CNC machine tool for cutting and performing milling operations according to a predetermined cutting path. It can more accurately control the position and size of the split board, suitable for complex split board requirements. The edges after milling are smooth and flat, and can be directly used for welding. However, the machine milling and cutting process has a high cost and is not suitable for hig

When choosing the thickness of a PCB board, there are several main considerations to consider. 1. Mechanical strength A thinner PCB board usually has lower mechanical strength, while a thicker board will be more sturdy. Therefore, in application scenarios with high mechanical strength requirements, choosing a thicker PCB board thickness is more appropriate. 2. Welding performance The thickness of the PCB board also affects the welding performance. A thinner plate thickness can provide better thermal conductivity, making it easier to dissipate heat during the welding process. A thicker plate thickness can provide better welding strength. Therefore, in application scenarios involving welding, it is necessary to choose the appropriate PCB board thickness based on specific welding needs. 3. Cost and Space Restrictions Thicker plate thicknesses generally increase costs and occupy more space. In some application scenarios with cost and space limitations, it is necessary to choose a

In addition to the above considerations, the thickness of the PCB board also involves some details in the PCB manufacturing process. 1. Selection of PCB materials Choosing different PCB materials can affect the standard and range of PCB board thickness. For example, the thickness range of PCB boards made of FR-4 material is generally between 0.4mm and 6.0mm. 2. Thickness of Laminate (Multi Layer PCB) For multi-layer PCBs, the board thickness is generally the sum of the thicknesses of each laminate. For example, for a 4-layer PCB, if the thickness of each laminate is 0.2mm, then the thickness of the entire PCB is 0.8mm. 3. Special needs In some special application scenarios, very thin or very thick PCB board thickness may be required. For example, some flexible PCBs (FlexPCBs) can have a board thickness of less than 0.1mm, while some high-power electronic devices may require a thicker board thickness to ensure heat dissipation.

The medical industry has high requirements for the reliability and safety of electronic devices. As an important component of medical equipment, medical PCB boards have correspondingly high standards and requirements to ensure the normal operation of medical equipment and the safety of patients. Let's take a look at some specifications and standards for medical PCB boards. 1. Material selection specifications: Medical PCB boards must be made of materials that comply with medical industry standards. These materials need to undergo strict safety and reliability testing to avoid any negative impact on patient health. 2. Electrical performance specifications: Medical PCB boards need to have good electrical performance, including stable voltage output, low noise, and low power consumption. These performance requirements are achieved through appropriate design and high-quality components to ensure the normal operation and accuracy of medical equipment. 3. Environmental adaptability

PCB circuit board reflow soldering is one of the common welding methods in the electronic assembly process. It firmly fixes electronic components on the PCB board by applying appropriate heat and melted solder paste to pre arranged welding points. However, some common problems may also arise during the reflow soldering manufacturing process. Introduce these issues and corresponding solutions. 1、 Tin splashing on the board surface Problem description: Tin splashing on the board refers to the excessive amount of solder around the welding point during reflow soldering. This may cause damage to components near the welding point, and even cause short circuits or welding failures. Solution: There are several methods to solve the problem of tin splashing on the board surface. Firstly, check whether the size and position of the welding points are appropriate to avoid excessive soldering caused by design defects. Secondly, adjust the temperature and speed in the reflow soldering furnace

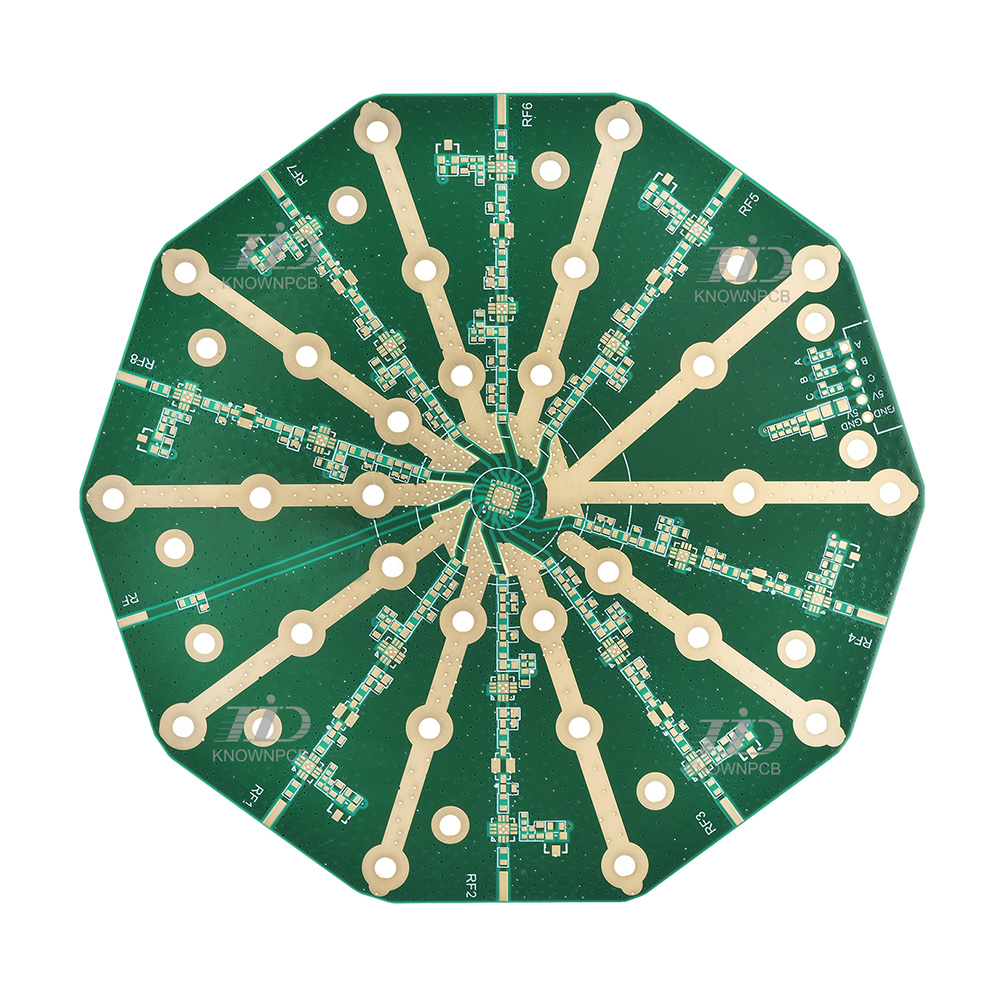

1、 The Function and Significance of High Frequency Board in Drone PCB A high-frequency board is a printed circuit board specifically designed for processing high-frequency signals. In unmanned aerial vehicles, the processing of high-frequency signals is very important. Drones typically use high-frequency devices such as radar, communication equipment, and radio equipment to achieve their functions. And these high-frequency devices require high-frequency boards to ensure the stability and reliability of signal transmission. High frequency boards can effectively reduce signal transmission loss and improve transmission efficiency. Therefore, using high-frequency boards can improve the performance of drones and increase their stability and reliability. 2、 Application of High Frequency Board in Drone PCB 1. Signal transmission The signals generated by high-frequency devices in drones must be transmitted to the corresponding positions through the transmission line of the drone PCB. T

1. Appearance observation method: The number of layers of a PCB board can be preliminarily determined by observing its appearance with naked eyes. Under naked eye observation, multi-layer PCB boards appear thicker, while single-layer or double-layer PCB boards appear thinner. However, due to the trend of miniaturization in modern electronic products, many PCB boards are very thin, making it difficult to determine the number of layers solely based on their appearance. 2. Line density method: By observing the circuit density on the PCB board, the number of layers can be determined. In general, the circuits on multi-layer PCB boards are denser and more complex between circuits. By comparing with empirical data, the number of layers of PCB boards can be preliminarily determined. 3. Cross hair method: This is a commonly used judgment method that requires the use of a microscope and a crosshair ruler. Using a microscope to observe the edges of a PCB board and measuring the thickness

Firstly, the first step in the production of new energy vehicle PCB boards is the design of circuit board drawings. The designer draws the layout and circuit connection drawings of the circuit board based on the functional and dimensional requirements of the electronic equipment of the new energy vehicle. The accuracy and rationality of design drawings are crucial for the subsequent manufacturing process. Next is the plate making and electroplating of the circuit board. Plate making is the process of transferring design drawings to photoresist through lithography technology, and then gradually exposing the copper layer through chemical corrosion to form the required circuit lines. Next, the copper plate is immersed in an electroplating bath, and through the action of current, a layer of copper foil is formed on the circuit line to enhance conductivity and durability. The third key step is drilling and deburring. In this step, the high-speed drilling on the small lathe drills n

In recent years, with the continuous development of electronic products and the further advancement of intelligence, the design of printed circuit boards (PCBs) has become increasingly important. The design of PCB multilayer structure occupies a core position in modern electronic equipment, and its rationality directly affects the performance and reliability of electronic products. Firstly, let's take a look at the design principles of a multi layer PCB structure. Firstly, the selection of layers is very important. The more layers there are, the higher the complexity of signal transmission, so a balance between circuit complexity, electromagnetic interference, and cost needs to be considered in the design. Secondly, in the design of PCB multilayer boards, the signal circuits of each layer should be reasonably arranged. There should be sufficient spacing between different signal lines to avoid mutual interference. In order to improve the speed of signal transmission and reduce e

With the continuous development of technology, LED circuit boards are playing an increasingly important role in the lighting industry. They not only provide high brightness lighting effects, but also have advantages such as energy conservation, environmental protection, and long service life. In order to further promote the development of LED light circuit boards, new design trends are constantly emerging. Today, the editor will delve into the current 5 cutting-edge LED light board PCB design trends and look forward to the possibilities that technology can bring to the future. Firstly, customized design has become mainstream. Traditionally, the design of LED light circuit boards has been relatively uniform, but now the market demand is constantly personalized, and people's requirements for lighting are becoming increasingly diverse. Therefore, more and more lamp panel manufacturers are providing customized design services to meet the needs of different customers. Customized des

1、 The Function and Significance of High Frequency Board in Drone PCB A high-frequency board is a printed circuit board specifically designed for processing high-frequency signals. In unmanned aerial vehicles, the processing of high-frequency signals is very important. Drones typically use high-frequency devices such as radar, communication equipment, and radio equipment to achieve their functions. And these high-frequency devices require high-frequency boards to ensure the stability and reliability of signal transmission. High frequency boards can effectively reduce signal transmission loss and improve transmission efficiency. Therefore, using high-frequency boards can improve the performance of drones and increase their stability and reliability. 2、 Application of High Frequency Board in Drone PCB 1. Signal transmission The signals generated by high-frequency devices in drones must be transmitted to the corresponding positions through the transmission line of the drone PCB. T

PCB circuit board reflow soldering is one of the common welding methods in the electronic assembly process. It firmly fixes electronic components on the PCB board by applying appropriate heat and melted solder paste to pre arranged welding points. However, some common problems may also arise during the reflow soldering manufacturing process. The manufacturer of intelligent circuit boards will introduce these issues and corresponding solutions.1、 Tin splashing on the board surfaceProblem description: Tin splashing on the board refers to the excessive amount of solder around the welding point during reflow soldering. This may cause damage to components near the welding point, and even cause short circuits or welding failures.Solution: There are several methods to solve the problem of tin splashing on the board surface. Firstly, check whether the size and position of the welding points are appropriate to avoid excessive soldering caused by design defects. Secondly, adjust the

In the manufacturing of electronic products, PCB (Printed Circuit Board) is a very important component. The number of layers on a PCB board determines the complexity and functionality of the circuit. Therefore, understanding and accurately determining the number of layers of PCB boards is crucial for the design and manufacturing of electronic products. So, how to accurately determine the number of layers of a PCB board? The editor of the manufacturer of intelligent circuit boards will take you to understand. Generally speaking, the following methods can be used to make judgments: 1. Appearance observation method: The number of layers of a PCB board can be preliminarily determined by observing its appearance with naked eyes. Under naked eye observation, multi-layer PCB boards appear thicker, while single-layer or double-layer PCB boards appear thinner. However, due to the trend of miniaturization in modern electronic products, many PCB boards are very thin, making it difficult to

1. Material selection specifications: Medical PCB boards must be made of materials that comply with medical industry standards. These materials need to undergo strict safety and reliability testing to avoid any negative impact on patient health. 2. Electrical performance specifications: Medical PCB boards need to have good electrical performance, including stable voltage output, low noise, and low power consumption. These performance requirements are achieved through appropriate design and high-quality components to ensure the normal operation and accuracy of medical equipment. 3. Environmental adaptability specifications: Medical equipment may be affected by various environmental conditions during use, including temperature, humidity, and vibration. Therefore, medical PCB boards need to have good environmental adaptability to ensure reliability and stability under various extreme conditions. 4. Production process specifications: The production of medical PCB boards needs to

1. Appearance inspection: Check whether the tin material is intact, whether there are obvious crystalline, powdery, fibrous and other foreign objects, and whether there are drag marks, spots and other phenomena. 2. Wet tensile test: Check the tensile strength, elongation at break, and modulus at break of the tin material. 3. Wet bending test: Check the bending strength and fracture modulus of the tin material. 4. Hot tempering test: Check the heat resistance of the tin material. 5. Resistivity test: Check the resistivity of the tin material. 6. Corrosion resistance inspection: Detect the corrosion resistance of the tin material, check whether there is agglomeration and corrosion phenomenon in the tin material. 7. Surface corrosion resistance test: Check the surface corrosion resistance of the tin material and check for any corrosion marks on the surface.

The influence of welding process parameters on the surface quality of welding is quite complex, mainly including the following key points: 1. Control of preheating temperature The function of preheating: ① Fully volatilize the solvent in the soldering flux to avoid affecting the wetting of the printed board and the formation of solder joints when the printed board passes through soldering; ② Bring the printed circuit board to a certain temperature before welding to prevent warping and deformation caused by thermal shock. Based on our experience, the preheating temperature is generally controlled at 180 200 ℃ and the preheating time is 1-3 minutes. 2. Welding rail inclination angle The inclination angle of the track has a significant impact on the welding effect, especially when welding high-density SMT devices. When the inclination angle is too small, bridging is more likely to occur, especially in welding, where the "shielding area" of SMT devices is more prone to bridging; If

Inquiry Now