+86 755 2794 4155

+86 755 2794 4155  sales@knownpcb.com

sales@knownpcb.com

-

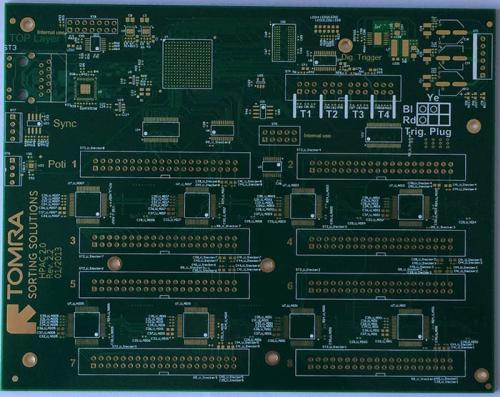

Shenzhen KNOWNPCB Technology Co., Ltd.

+86 755 2794 4155

+86 755 2794 4155  sales@knownpcb.com

sales@knownpcb.com

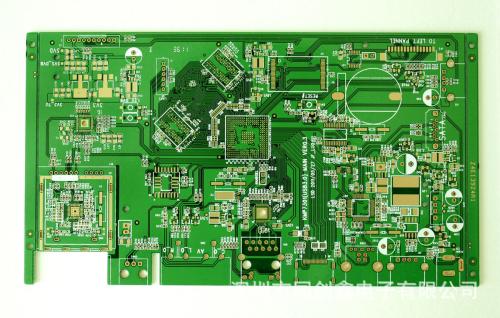

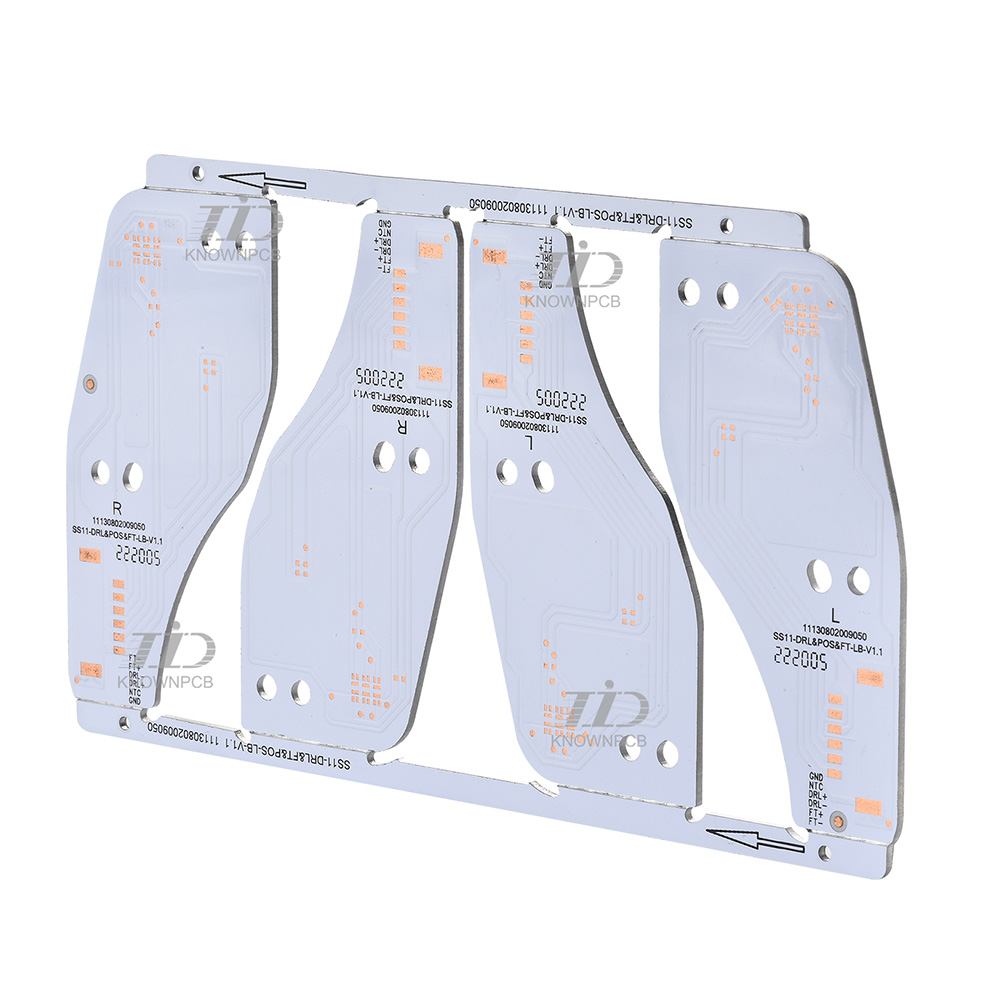

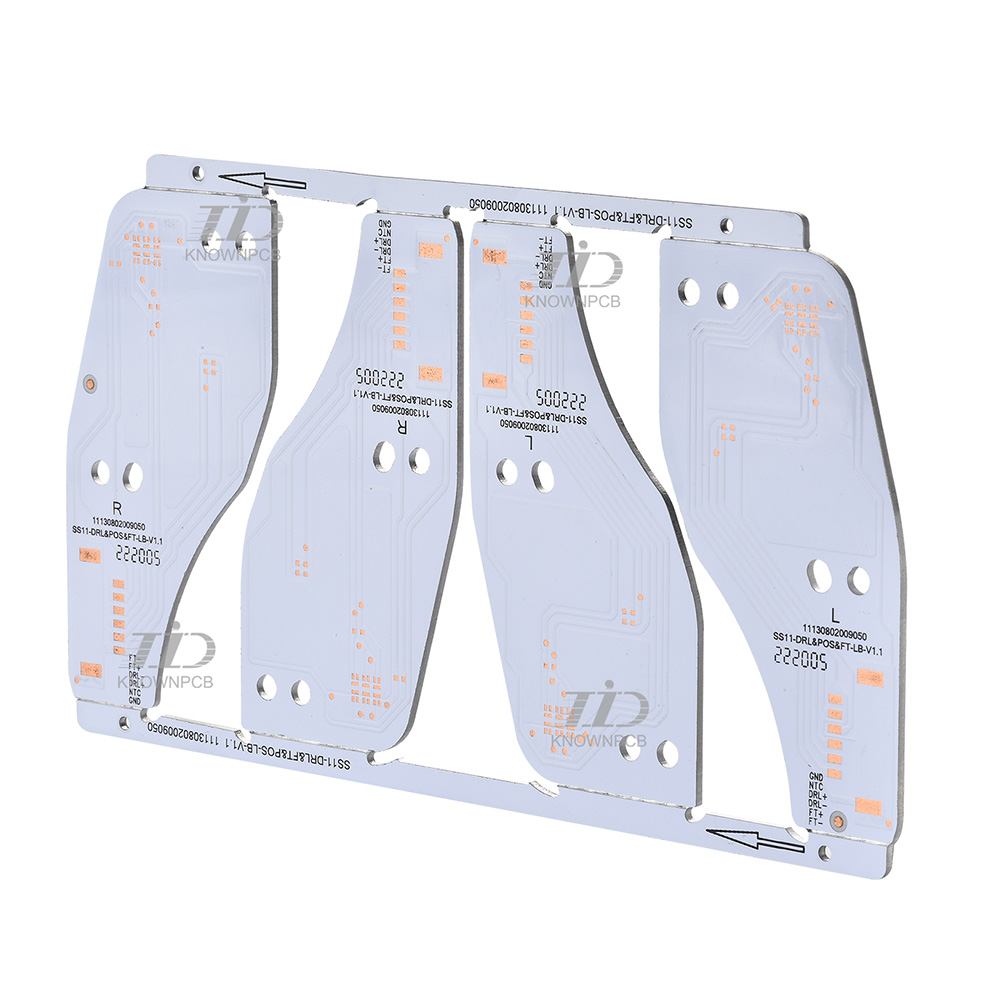

Have you noticed that now more and more of our lighting is using led lighting.What is LED? Compared to the traditional light bulbs, LEDs have lower power consumption, longer lifetime and higher energy efficiency. In the PCB industry,when we say LED PCB, it refers to the pcb used for LED lighting, if you are looking for a suitable LED PCB for your lighting system, this article may bring you something. WHAT ARE LEDS COMPOSED OF?LED is an initial light-emitting diode that produces light when an electric current passes through. LEDs typically have negative and positive electrodes, which generate light in the visible light region.The LEDS are glued to the PCB by soldering process and have electrical connections for lighting.Since light-emitting diodes dissipate a lot of heat when they are in use, when you are designing LED, the metal core is usually the best choice for LED PCB, it is because that it dissipates heat more faster. Among them, the metal material aluminum is the most widely used

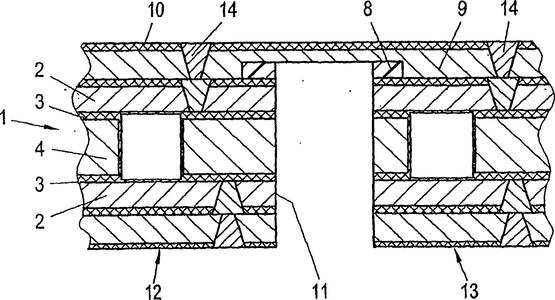

The so-called blind hole circuit board refers to non drilled holes. The difference between blind holes and through holes is that through holes are holes drilled through each layer. When making blind hole boards, drilling is done before pressing, while through holes are drilled after pressing. What basic knowledge do you need to know in the manufacturing of blind hole PCB circuit boards Blind hole PCB circuit board ① Drill tape: Select through holes as unit reference holes. Each blind hole drill tape needs to select a hole and identify its corresponding unit reference hole coordinates, and note which drill tape corresponds to which layers. When the laser hole is sleeved with the inner buried hole, even if the holes of the two drill tapes are in the same position, it is necessary to confirm with the customer. Move the position of the laser hole to ensure electrical connection, and do not handle it arbitrarily based on experience. ② Process holes: The inner layer of ordinary multi-

1. Heat dissipation through the circuit board itself: Currently, the most widely used substrates for printed circuit boards are copper clad/epoxy glass cloth substrates, phenolic resin glass cloth substrates, paper based copper clad substrates, etc. Although these substrates have good electrical and processing properties, their heat dissipation is poor, and they are still not competent for some products with high current requirements. With the continuous updating of precision products, The volume of the PCB board is also decreasing, but the precision is constantly increasing. If only the surface is used for heat dissipation, it is far from enough. The best way to solve this problem is to improve the heat dissipation ability of the PCB board itself, which is directly in contact with the heating element, and transmit heat out through the circuit board itself. 2. When designing a PCB circuit board, a reasonable circuit layout can also achieve heat dissipation. Apart from the poor the

The color of the solder mask layer mainly depends on the color of the solder mask ink. Green ink is currently the most widely used and the cheapest in the market. In fact, the soldering ink on the market is not only limited to green, but also has various colors such as red, blue, purple, black, and yellow. However, green is the most common, and the main reason is that using green soldering ink has the following advantages: it is easy for optical positioning correction. The production process of the circuit board itself includes the STM welding process, which requires soldering and final AOI verification. These processes require optical positioning calibration, and the green background color has a better recognition effect on the instrument. The visual effect is better in the yellow light room. The entire PCB board product undergoes processes such as board making and SMT during the production process. Usually, when circuit boards are used in the production and processing of electroni

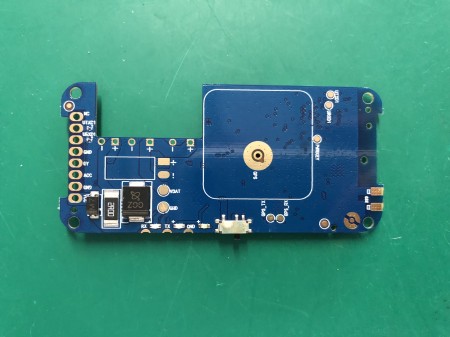

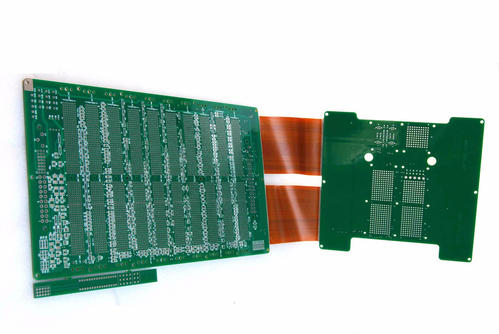

FPC flexible circuit board is a highly reliable and excellent flexible printed circuit board made of PI polyimide or polyester film as the substrate. It has the characteristics of high wiring density, light weight, thin thickness, and good bending performance. PI, as a special engineering material, has been widely used in fields such as aviation, aerospace, microelectronics, nanomaterials, liquid crystals, separation membranes, lasers, etc. The long-term use temperature is between -200 ℃ and 426 ℃. PI polyimide is common in FPC flexible circuit boards, as it exists in substrates, covering films, and even reinforcement. Some people may be confused about this, so today let's discuss the difference between them? The functional differences between the substrate, covering film, and PI reinforcement of FPC flexible circuit boards are as follows: 1 PI substrate: For FPC flexible circuit board substrates, there are two types: adhesive substrate and non adhesive substrate. PI polyimide is

So, what are the components of FPC flexible circuit boards? In the structure of FPC flexible circuits, the materials composed of flexible copper clad laminate (FCCL), covering film, adhesive film, etc. Flexible Copper Clad Laminate (FCCL): The common film materials for flexible copper clad laminates include polyimide film (PI), polyester (PET), polyethylene naphthalate (PEN), liquid crystal display polymer (LCP), and other polymer plastic films. In FPC flexible circuit boards, copper clad boards mainly play three roles: conductivity, insulation layer, and support points. Covering film: It is composed of organic chemical plastic film and adhesive, and its function is to maintain a part of the flexible power circuit electrical conductor that has already been carried out. There are different types of adhesive films and adhesive types, as well as thickness specifications and models for adhesive films. Adhesive film: It is formed by pouring adhesive on two or one side of a substrate f

Regarding FPC soft boards, also known as flexible circuit boards, they are actually a type of printed circuit board, but there are significant differences from traditional printed circuit boards. Therefore, they are referred to as FPC soft boards, also known as flexible circuit boards. FPC generally uses PI as the substrate and is a flexible material that can be bent or flexed arbitrarily. FPC soft boards are usually used for links that require repeated bending and some small components, but now it's not just that. Currently, smartphones are considering bending prevention, which requires the use of FPC soft boards as a key technology. PCB is the so-called printed circuit board, usually referred to as PCB hard board, which is the support body in electronic components and is a very important electronic component. PCB hard boards usually use FR4 as the substrate, also known as FR4 circuit boards, and cannot be bent or bent. PCB hard boards are usually used in places that do not requi

The trend research on PCB sampling technology began to be implemented at the end of 2011, including English and Chinese versions. 41 PCB sample manufacturing companies participated in the survey, including dominant companies from Asia, Europe, and North America. They hold a 16.5% share of the global PCB market. The IPC research sample is representative of the global industry in terms of company size and product portfolio. Among the companies studying the trend of PCB sampling technology, the production of high-density interconnect (HDI) boards is expected to increase by 26% between 2011 and 2014. Stacking and interleaving micropores technology will also be widely used, thereby affecting the performance of any layer of micropores and any through-hole. With trends driven by miniaturization and high-speed technology, surveys have shown that the two most common factors limiting circuit scale miniaturization are solder mask pattern alignment and assembly. Most companies are evaluating

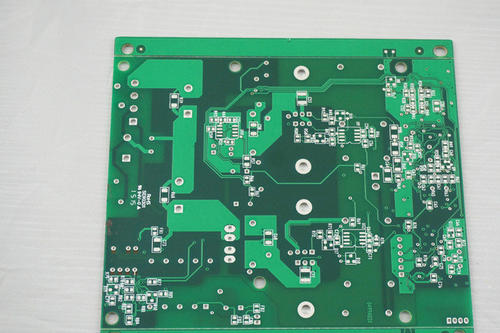

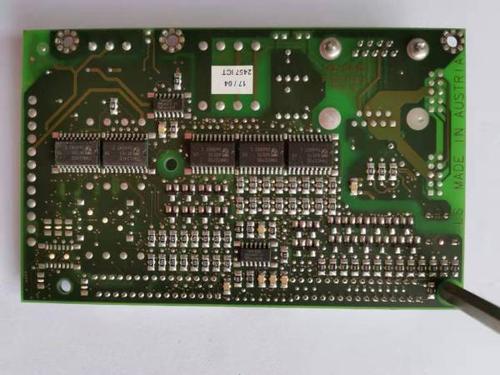

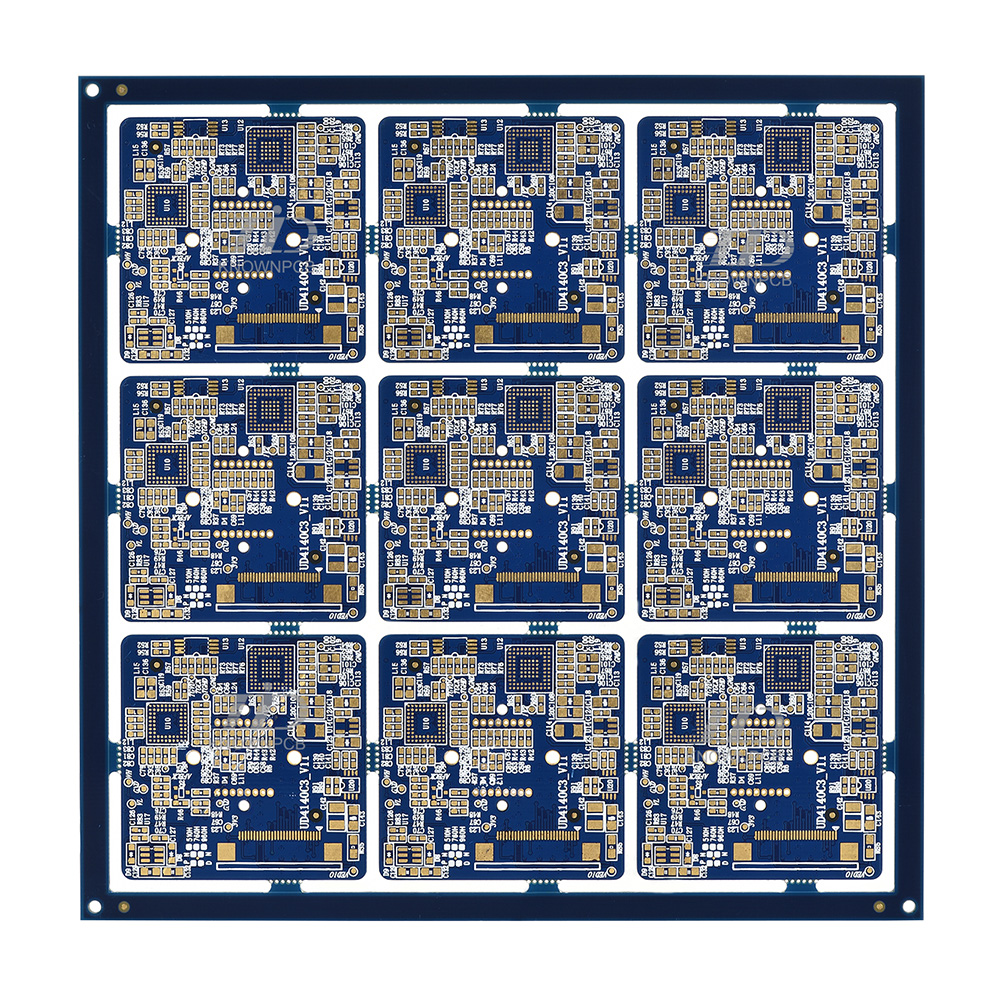

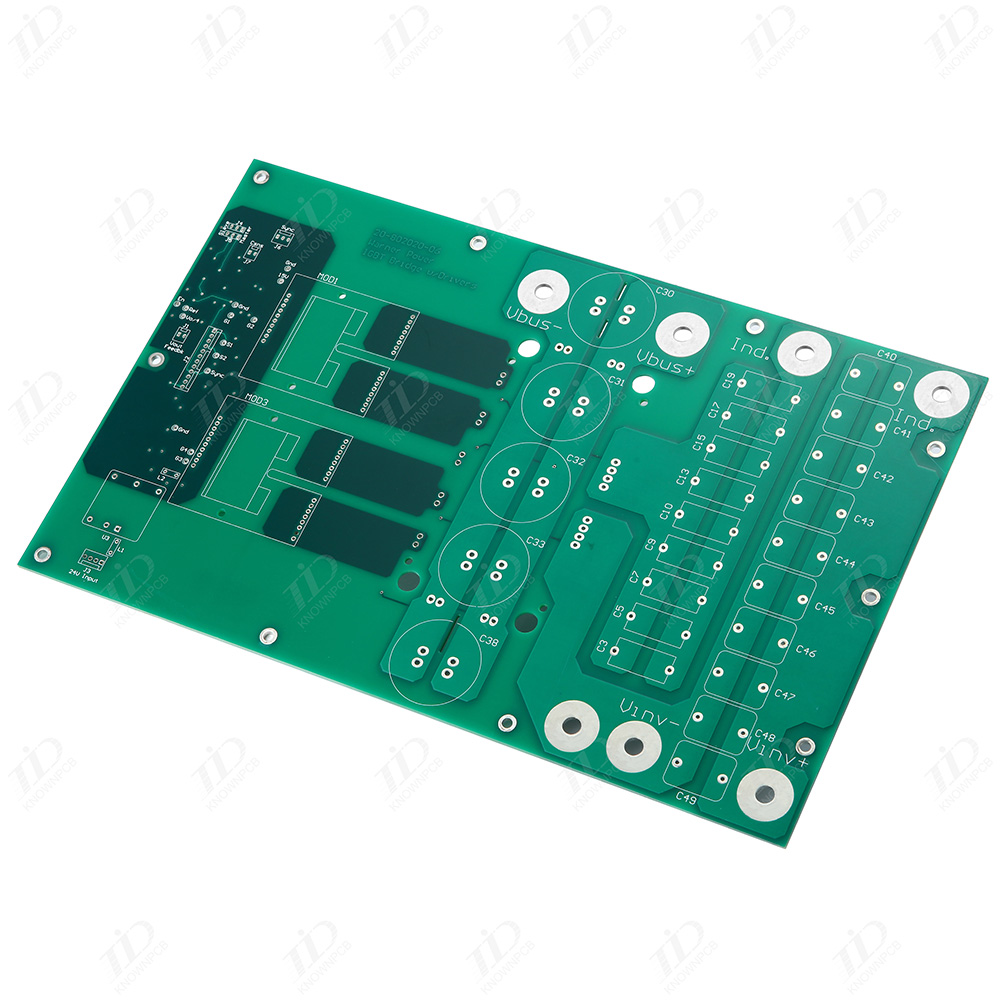

Printed circuit boards (PCBs), also known as circuit boards, are important electronic components and are known as the "mother of electronic components". 1. Traditional circuit boards are also known as printed circuit boards and printed circuit boards, as they are made by printing corrosion-resistant agents. At present, most circuit boards are coated with anti-corrosion agents (laminated or coated), and after exposure and development, the circuit board can be etched. 2. Circuit boards include single panel, double-sided board, and multi-layer board. In the most basic PCB, components on one side and wires on the other side are called single panels. The double-layer panel is covered with copper on both sides, and the lines between the two layers can be connected through through-holes to form the required network connection. Multilayer board refers to a printed board with three or more layers of conductive patterns, with insulating materials in the middle, and conductive patterns connec

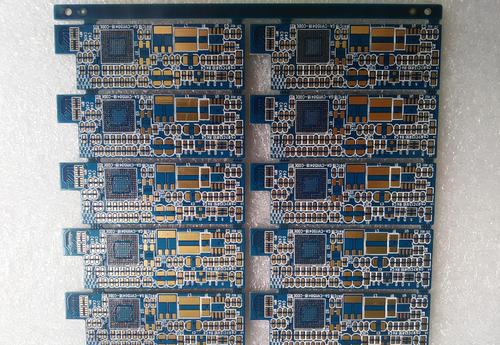

The so-called PCB sampling actually refers to the trial production of printed circuit boards before mass production, which is the process of electronic engineers designing circuits and completing PCBs, and PCB manufacturers conducting small-scale trial production. After the sample testing is completed, mass production will be carried out. There are two methods for sampling, one is a legitimate PCB factory, and the other is a professional sampling company. PCB sampling generally includes two groups, one is the engineer group, and the other is the PCB sampling manufacturer. As a team of engineers, attention should be paid to the following aspects when making samples: 1. Only by carefully selecting the sample size can we effectively control costs. 2. Confirm the packaging of the equipment to avoid packaging errors that may lead to sample failure. 3. Conduct comprehensive electrical testing to improve the electrical performance of the PCB board. 4. Complete signal integrity layout, re

In recent years, Pcb liquid medicine has gradually shifted from being environmentally friendly to being environmentally friendly. The government has increased its punishment efforts, and the industry and PCB manufacturers or suppliers have begun to pay close attention to environmental issues. Environmentally friendly chemical solutions emit less exhaust gas, wastewater, and waste, making them easy to handle, creating a friendly working environment, and providing more protection for workers' physical health. For example, in the field of porous metals, in recent years, more and more PCB companies have chosen organic conductive film direct electroplating. This metallization process does not emit formaldehyde gas, which not only greatly improves the working environment, but also has no complex wastewater and simple treatment methods, greatly saving water and electricity, and reducing operating costs. Wise individuals in the PCB industry have begun to call for the innovation of PCB ma

What is the thermal design in PCB processing? What aspects do we need to understand this problem from? The use range of thermocouple temperature measurement is very wide, and the problems encountered are also diverse. Therefore, this chapter can only cover several important aspects of thermocouple temperature measurement. Thermocouples are still one of the main means of temperature measurement in many industries, especially in the steelmaking and petrochemical industries. However, with the advancement of electronics, the application of resistance thermometers in industry has become increasingly widespread, and thermocouples are no longer the only and most important industrial thermometers. The practical application of thermoelectric phenomena is, of course, the use of thermocouples to measure temperature. The complex relationship between electron energy and scattering results in different thermoelectric potentials of different metals. Since a thermocouple is such a device, the dif

1: The development of electronic components, the development of integrated circuits - IC, and the diverse use of semiconductor materials; 2: Electronic products pursue miniaturization, and the original perforated inserts cannot meet the requirements; 3: The revolution in electronic technology is indeed necessary to pursue international trends. 4: SMT processing has a more complete function in electronic products, and the integrated circuits currently used - ICs - no longer have perforated inserts, especially large-scale and highly integrated ICs that have to use surface mount technology; 5: PCB sampling, mass production, automation, and production enterprises strive to improve product quality and reduce production costs in order to improve their competitiveness and meet customer needs;

What are some issues to pay attention to in the appearance method of PCB processing? Here are a few points for everyone to have a more comprehensive understanding of some issues related to PCB processing. Understanding these issues clearly is believed that everyone will also gain more knowledge in the field of processing: 1: When adjusting the mold, try to use manual operation instead of manual operation. 2: Start the punching machine and conduct a comprehensive inspection to ensure that all parts, including the clutch, brake, slider, etc., are functioning properly, the operating mechanism is reliable, and there is no continuous punching phenomenon. 3: Prepare several sets of pressure plates and T-head pressure plate screws for use with the mold. The front end of the pressing plate should not touch the straight wall of the lower mold. Sandcloth should be placed between the contact surfaces, and the screws must be tightened. 4: To improve the punching performance of the substrat

What do we need to know about some passive components in SMT processing? Here you can have a comprehensive understanding of these aspects: 1: Inductor: The ability of a coil to store energy in a magnetic field is called an inductor, and this coil is called an inductor. The main function of inductors is to prevent interference from electromagnetic waves and filter noise in the current. They are widely used, but the technology and scale of chip inductors produced in China are still insufficient, and there is no professional manufacturer of inductors. Resistor: The function of a resistor is to regulate the voltage and current in a circuit, which can be divided into three categories based on material and product packaging. 2: Capacitor: When two conductive substances are separated by a medium and used to store potential static electricity, it is called a capacitor. There are various types of capacitors, which can be divided into more than 30 types based on the materials used. Domest

As usual, paying attention to some details can eliminate unwanted situations, such as misprints of solder paste and removal of solidified solder paste from the board. Our goal is to deposit an appropriate amount of solder paste at the desired location. Dirty tools, dry solder paste, and misalignment between the template and the board can all cause unwanted solder paste on the bottom surface of the template or even on the assembly. During the printing process, wipe the template according to a certain pattern between printing cycles. Ensure that the template is located on the solder pad, not on the solder mask layer, to ensure a clean solder paste printing process. Online and real-time solder paste inspection and pre reflow inspection after component installation are both helpful process steps for reducing process defects before welding occurs. For fine-pitch templates, if the thin template cross-section is bent and causes damage between pins, it can cause solder paste to deposit bet

Nowadays, more and more electronic companies are starting to provide personalized PCB board sampling and customization services. There is no fixed range of prices, and prices need to be determined based on the size, quantity, process, special process, delivery time, packaging type, etc. of the circuit board you need to customize. So, how can so many PCB personalized customization companies find a suitable PCB personalized customization company for themselves? This article will explain to you from 8 aspects. Customer Experience A good reputation is the primary factor for us to refer to when choosing personalized customized services for PCB sampling. When selecting a manufacturer for multi-layer PCB board sampling, we can first search for relevant information and information about the manufacturer at the internet level. Manufacturers with their own official website are definitely trustworthy. Only a website is not enough, but it also depends on whether the website has updates on co

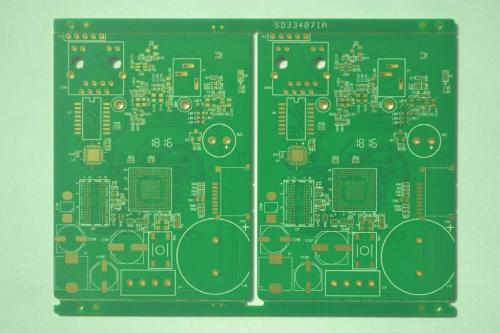

In daily life, the composition of various electronic devices inevitably requires the use of PCB circuit boards. PCB sampling is a provider of electrical connections for electronic components. According to different product design and usage requirements, PCB sampling can also be divided into single-layer boards, double-layer boards, and multi-layer boards. Multilayer boards are currently the most commonly used type of PCB. So what are the application advantages of multi-layer PCB board sampling? Below, the quick technician will organize and introduce for everyone. The application advantages of multi-layer PCB circuit boards: 1. High assembly density, small size, and light weight meet the needs of miniaturization of electronic equipment; 2. Due to the high assembly density, the wiring between various components (including components) is reduced, installation is simple, and reliability is high; 3. Due to the repeatability and consistency of graphics, errors in wiring and assembly a

Reflow soldering is a very important process in SMT chip processing, which involves combining the chip components with the solder pads on the circuit board at high temperatures and then cooling them together, greatly affecting the stability of the circuit board. In reflow soldering, some process defects are also prone to occur, and the reasons need to be analyzed and targeted solutions are needed to ensure product quality. Below, the quick technician will mainly organize and introduce the common defects and cause analysis of SMT reflow soldering for everyone. 1、 Tin bead Reason: 1. The silk screen holes are not aligned with the solder pads, and the printing is not accurate, causing solder paste to stain the PCB. 2. Solder paste is exposed too much in an oxidizing environment and absorbs too much water from the air. 3. Heating is inaccurate, too slow and uneven. 4. The heating rate is too fast and the preheating interval is too long. 5. The solder paste dries too quickly. 6.

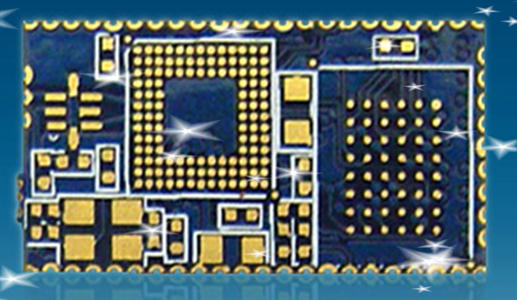

Firstly, the application prospects of microcircuit boards in the field of smartphones are very broad. Nowadays, smartphones have become an essential communication tool in people's lives. The application of micro circuit boards has made smartphones more intelligent and multifunctional. The small size and high integration of microcircuit boards enable smartphones to have stronger computing power and richer functions, such as facial recognition, fingerprint recognition, virtual reality, and so on. Moreover, the rapid development of micro circuit boards has also brought about improvements in the performance and price of smartphones, allowing more people to enjoy the convenience and fun brought by smartphones. Secondly, the application prospects of micro circuit boards in the field of smart homes are also very broad. With the improvement of people's living standards, the requirements for living environment are also increasing. Smart home, as an emerging way of life, is gradually bein

Firstly, one of the difficulties in designing and manufacturing high-frequency high-speed boards is ensuring signal integrity. Due to the transmission characteristics of high-frequency signals, the requirements for signal integrity are very high. Once the signal experiences attenuation, interference, or distortion, it will lead to a decrease in system performance or even malfunction. The key to solving the problem of signal integrity is to choose materials, wiring, and grounding methods reasonably, and conduct strict signal integrity simulation and testing. Secondly, the design and production of high-frequency high-speed boards also face challenges in terms of high-frequency characteristics and electromagnetic compatibility. In the transmission of high-frequency and high-speed signals, electromagnetic wave radiation and interference will become a serious problem. In order to improve electromagnetic compatibility, it is necessary to design and layout devices, pins, and ground wir

Inquiry Now