+86 755 2794 4155

+86 755 2794 4155  sales@knownpcb.com

sales@knownpcb.com

-

Shenzhen KNOWNPCB Technology Co., Ltd.

+86 755 2794 4155

+86 755 2794 4155  sales@knownpcb.com

sales@knownpcb.com

Have you noticed that now more and more of our lighting is using led lighting.What is LED? Compared to the traditional light bulbs, LEDs have lower power consumption, longer lifetime and higher energy efficiency. In the PCB industry,when we say LED PCB, it refers to the pcb used for LED lighting, if you are looking for a suitable LED PCB for your lighting system, this article may bring you something. WHAT ARE LEDS COMPOSED OF?LED is an initial light-emitting diode that produces light when an electric current passes through. LEDs typically have negative and positive electrodes, which generate light in the visible light region.The LEDS are glued to the PCB by soldering process and have electrical connections for lighting.Since light-emitting diodes dissipate a lot of heat when they are in use, when you are designing LED, the metal core is usually the best choice for LED PCB, it is because that it dissipates heat more faster. Among them, the metal material aluminum is the most widely used

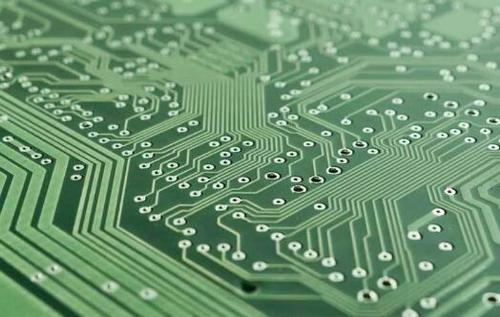

In PCB design, wiring is an important step in completing product design, and it can be said that the previous preparation work was done for it. PCB wiring includes single-sided wiring, double-sided wiring, and multi-layer wiring. There are also two types of wiring methods: automatic wiring and interactive wiring. Today, let professional engineers explain in detail what PCB wiring rules and techniques are available for you? 1. Handling of power and ground wires The interference caused by improper handling of power and ground wires can lead to a decrease in product performance, and sometimes even affect the success rate of the product. Therefore, the wiring of power and ground wires should be taken seriously, and the noise interference generated by the power and ground wires should be minimized to ensure the quality of the product. The specific approach is as follows: (1) Add a coupling capacitor between the power supply and ground wire. (2) Try to widen the width of the power a

Copper deposition is the abbreviation for chemical copper plating, also known as through hole plating, abbreviated as PTH. It refers to the chemical deposition of a thin layer of chemical copper on a non conductive hole wall substrate that has been drilled, to serve as the substrate for subsequent copper plating. So, what are the processes for copper deposition on PCB circuit boards? Let's take a look together with the editor: 1、 Decomposition of PTH process: Alkaline degreasing → Second or third stage countercurrent rinsing → Coarsening (micro etching) → Second stage countercurrent rinsing → Pre leaching → Activation → Second stage countercurrent rinsing → Gelation → Second stage countercurrent rinsing → Copper precipitation → Second stage countercurrent rinsing → Acid leaching. 2、 Detailed process explanation of PTH: 1. Alkaline degreasing: Remove oil stains, fingerprints, oxides, and dust inside the holes on the board surface; Adjust the pore wall from negative charge to pos

Filtering technology is an effective measure to suppress interference, especially in dealing with conducted interference and certain radiated interference of EMI signals in switching power supplies, which has obvious effects. So, what issues should we pay attention to regarding PCB circuit board filtering technology? 1. Differential mode interference and common mode interference Any conducted interference signal on the power line can be represented by differential and common mode interference signals. In general, the amplitude of differential mode interference is small, the frequency is low, and the interference caused is relatively small; Common mode interference has a large amplitude and high frequency, and can also generate radiation through wires, resulting in significant interference. Therefore, in order to weaken conducted interference, the EMI signal should be controlled below the limit level specified in relevant EMC standards. In addition to suppressing interference sou

Firstly, distinguish the quality of FPC circuit boards from their appearance: 1. Standards for size and thickness. Customers can measure and check whether the product meets the thickness and specifications specified in the production drawings. 2. Light and color. Circuit boards are all covered with ink. If the color of the board is not bright and there is less ink, it indicates that the quality of the board itself is not good. 3. Weld appearance. Due to the large number of parts on the circuit board, poor welding can lead to parts falling off easily. Careful identification can provide a preliminary assessment of quality. Secondly, high-quality FPC circuit boards have the following requirements: 1. It is required that the components be easy to use after installation, that is, the electrical connection should meet the requirements; 2. The line width, thickness, and distance of the line meet the requirements to avoid heating, open circuit, and short circuit of the line; 3. T

1. SIG GND (PWR) - PWR (GND) - SIG; 2. GND SIG (PWR) - SIG (PWR) - GND; The potential issue with the above two stacked designs is the traditional 1.6mm (62mil) plate thickness. The interlayer spacing will become large, which is not conducive to controlling impedance, interlayer coupling, and shielding; Especially, the large spacing between the power layers reduces the board capacitance, which is not conducive to filtering out noise. The first solution is usually applied in situations where there are many chips on the board. This solution can achieve good SI performance, but it is not very good for EMI performance. It mainly needs to be controlled through wiring and other details. The second solution is usually applied in situations where the chip density on the board is low enough and there is sufficient area around the chip. In this scheme, the outer layer of the PCB is a layer, and the middle two layers are both signal/power layers. From the perspective of EMI control, This

For two-layer boards, controlling EMI radiation is mainly considered from wiring and layout; The electromagnetic compatibility issues of single-layer and double-layer boards are becoming increasingly prominent. The main reason for this phenomenon is that the signal circuit area is too large, which not only generates strong electromagnetic radiation, but also makes the circuit sensitive to external interference. The simplest way to improve the electromagnetic compatibility of the circuit is to reduce the loop area of key signals; Key signals mainly refer to signals that generate strong radiation and signals that are sensitive to external boundaries. Single and double layer boards are typically used in low-frequency simulation designs below 10KHz: 1) Route the power supply in a radial pattern on the same layer and minimize the total length of the lines; 2) When using power and ground wires, approach each other closely; Lay a ground wire next to the critical signal line, which sho

The heat generated during the operation of electronic devices rapidly increases the internal temperature of the equipment. If this heat is not dissipated in a timely manner, the equipment will continue to heat up, and the reliability of electronic devices will decrease. Therefore, heat dissipation treatment for circuit boards is very important. So, what are the cooling methods for PCB circuit boards? 1. High heating device with heat sink and heat conduction plate. When there are a few components in the PCB that have a large heat output (less than 3), a heat sink or heat transfer tube can be added to the heating device; When the temperature cannot drop, a radiator with a fan can be used to enhance the heat dissipation effect. When there are a large number of heating devices (more than 3), a large heat dissipation cover (plate) can be used, and the heat dissipation cover can be buckled onto the surface of the components as a whole to dissipate heat in contact with each component. 2.

There is an old saying: PCB design involves 90% layout and 10% wiring. So, what are the skills for PCB wiring? 1. Don't rely on your automatic router Almost all PCB design software has a tool called an automatic router, but an automatic router will never replace itself in wiring and should only be used for a few reasons, including: Accurate. After placing all components, an automatic router can be used to view the completion level obtained. Bottleneck. You can also use an automatic router to discover bottlenecks and other critical connection points that may not be visible during component placement. Inspiration. You can use an automatic router as a source of inspiration to understand how to route some traces that you cannot complete. In addition to the above reasons, it is recommended not to rely on automatic wiring to complete all wiring on the layout of the circuit board. 2. Understand the manufacturer's specifications Before starting to lay copper wiring, please call or

1. Parasitic capacitance The through-hole itself has parasitic capacitance to the ground. If the diameter of the isolation hole on the floor layer of the through-hole is known to be D2, the diameter of the through-hole pad is D1, the thickness of the PCB board is T, and the dielectric constant of the board substrate is ε, The parasitic capacitance of the via is approximately C=1.41 ε TD1/(D2-D1). The main impact of parasitic capacitance on the circuit caused by vias is that it prolongs the rise time of the signal and reduces the speed of the circuit. For example, for a PCB board with a thickness of 50Mil, if a through-hole with an inner diameter of 10Mil and a pad diameter of 20Mil is used, and the distance between the pad and the ground copper area is 32Mil, we can approximately calculate the parasitic capacitance of the through-hole using the above formula as follows: C=1.41 × four point four × zero point zero five zero × 0.020/(0.032-0.020)=0.517pF The variation in rise time

Through holes (via) are an important component of PCB circuit boards, and the cost of drilling holes usually accounts for 30% to 40% of PCB manufacturing costs. Simply put, every hole on a PCB can be referred to as a through hole. So, what are the classification and composition of through-holes on PCB circuit boards? 1、 Classification of vias From the perspective of function, vias can be divided into two categories: one is used as electrical connections between layers; The second is used for fixing or positioning components. From a process perspective, through holes can be further divided into three categories: blind holes, buried holes, and through holes. Blind holes are located on the top and bottom surfaces of circuit boards, with a certain depth, used for connecting surface and inner circuits. The depth of the holes usually does not exceed a certain ratio (aperture). The buried hole is a connecting hole located on the inner layer of the circuit board, and it will not extend

High frequency board refers to a special type of circuit board with high electromagnetic frequency, used for PCBs in the fields of high frequency (frequency greater than 300MHz or wavelength less than 1 meter) and microwave (frequency greater than 3GHz or wavelength less than 0.1 meter). It is a circuit board produced on a microwave substrate copper clad board using partial processes of ordinary rigid circuit board manufacturing methods or special processing methods. Generally speaking, high-frequency boards can be defined as circuit boards with frequencies above 1GHz. So, what are the main factors to consider when choosing a suitable high-frequency PCB board? Let the editor decrypt it for you: 1. Manufacturability; For example, how about the multiple pressing performance, temperature performance, CAF/heat resistance, mechanical toughness (good reliability), and fire resistance level; 2. Various performance matching with the product (electrical, performance stability, etc.); Lo

1、 Contact the manufacturer Firstly, it is necessary to inform the manufacturer of the documents, process requirements, and quantity. Regarding "What parameters do you need to provide for PCB circuit board sampling to the manufacturer?" You can click on this article to learn and provide the necessary information. Then, professionals will provide you with quotations, place orders, and follow up on the production progress. 2、 Material cutting Purpose: According to the requirements of the engineering data MI, cut into small production pieces on large sheets that meet the requirements, and produce small pieces that meet the customer's requirements. Process: Large plate material → Cutting according to MI requirements → Curing plate → Fillet angle/edge grinding → Plate discharge 3、 Drilling Purpose: Based on engineering data, drill the required hole diameter at the corresponding position on the sheet material that meets the required size. Process: Stacking pin → Upper plate → Dril

Welding is an important process in PCB circuit board sampling. We often encounter many welding defects when making PCBs. So, what are the common welding defects of PCB circuit boards? 1. False soldering: There is a clear black boundary between solder and component leads or copper foil, and solder is concave towards the boundary. Hazard: The circuit board cannot function properly. Reason: 1) Component leads are not cleaned properly, not tin plated or oxidized; 2) The printed board was not cleaned properly and the quality of the soldering flux sprayed was poor. 2. Solder accumulation: The solder joint structure is loose, white, and dull. Hazard: Insufficient mechanical strength, possible false soldering. Reason: 1) Poor solder quality; 2) Insufficient welding temperature; 3) Loose component leads. 3. Excessive solder: The solder surface is convex. Hazard: Waste solder and may contain defects. Reason: The solder was evacuated too late. 4. Insufficient solder: The welding are

Many special components are often used in PCB layout, and if the layout is not handled properly, it will directly affect the performance and quality of the PCB circuit board. So, what are the layout requirements for special components on PCB circuit boards? 1. Layout requirements for crimping devices (1) There should be no components greater than 3mm around the crimping device surface, and no welding components should be present around 1.5mm; There must be no components within a distance of 2.5mm from the center of the pin hole of the crimping device on the opposite side of the crimping device. (2) There should be no components within 1mm around the crimping device. 2. Layout requirements for thermal sensitive devices (1) Thermal sensitive devices (such as electrolytic capacitors, crystal oscillators, etc.) should be kept away from high thermal devices as much as possible. (2) The thermal sensitive device should be tightly attached to the tested component and away from the hi

PCB circuit boards can be divided into single-sided, double-sided, and multi-layer. Multilayer boards refer to circuit boards with more than 4 layers, and currently there are over 100 layers of PCBs. Why are PCB multilayer boards even numbered? 1. Relatively speaking, even layer PCBs do have more advantages than odd layer PCBs. Due to the lack of a layer of medium and foil, the raw material cost of odd layer PCBs is slightly lower than that of even layer PCBs, but its processing cost is significantly higher than that of even layer PCBs. Odd layer PCBs require the addition of non-standard laminated core bonding processes on top of the core structure process. Before lamination bonding, the outer core requires additional processing, which increases the risk of scratches and etching errors on the outer layer. 2. Odd layer circuit boards are prone to bending. When the PCB cools down after the multi-layer circuit bonding process, different lamination tensions can cause the PCB to bend.

The question that many newcomers ask the most is: why are the vast majority of PCB board colors green? Today, the PCB engineer will come to answer this question for you. 1. Green ink is currently the most widely used and long-lasting ink, and it is also the cheapest in the market. Therefore, green is widely used as the main color for PCB products by many manufacturers. 2. Usually, during the production of PCB circuit boards, there are several processes that must go through the yellow light chamber, because green has a better effect in the yellow light chamber than other colors. In addition, when soldering components in SMT, PCB circuit board production needs to go through solder paste and lamination, as well as the final AOI calibration process. Optical positioning calibration is required, and boards with a green background color have better recognition effect on the instrument. 3. The production of PCB circuit boards may not necessarily be green, it depends on the color that the

Many customers often ask: What are the common problems encountered in PCB circuit board design? Let professional PCB manufacturers tell you below. 1. Why do we try not to split across power sources when wiring? Because the signal spans different power layers, its return path becomes longer and more susceptible to interference. Of course, low-speed signals are acceptable, but high-speed signals should be carefully checked and avoided crossing as much as possible. 2. Some boards may have external input and output interfaces, and if their grounding design is not good, it can also affect normal operation and become a source of external electromagnetic interference, sending out the noise inside the board. Generally speaking, a separate interface ground will be separated and connected to the signal ground through thin wiring, which can be connected in series with a resistance of 0 ohms or a small resistance value. Common grounding symbols: PE, PGND, FG - protective grounding or casin

PCB layout and design have a significant impact on the way a circuit works, therefore, if printed circuit boards are designed in an effective manner, the circuit will work more reliably within its specification range. So, what are the issues to pay attention to in the layout and design of PCB circuit boards? 1. PCB design equipment For commercial development programs, CAD and computer-aided design packages may be required due to complexity. The functionality of PCB software varies greatly. Budget and even free software provide basic functions, while high-end software packages allow for more features to be included in the design. Simulation, complex routing, and more features are available. 2. Circuit schematic capture The first step in PCB design is to capture the circuit schematic. The circuit can be input into the schematic capture tool and can also be simulated during this stage. For applications such as RF circuit design, circuit simulation can lead to more optimization of

PCB design is an important step before PCB production. If not designed well, it will directly affect the performance and quality of the circuit board, causing the entire circuit board to be scrapped; Layout of components is an important aspect of PCB design. So, what are the requirements for PCB design and layout of components? 1. Aesthetics When designing a PCB, it is not only important to consider the orderly placement of components, but also to consider the graceful and smooth wiring. 2. Force The circuit board should be able to withstand various external forces and vibrations during installation and operation: it should have a reasonable shape, and the positions of various holes on the board should be arranged reasonably; Generally, the distance between the hole and the board edge should be at least greater than the diameter of the hole; It should also be noted that the weakest section of the plate caused by irregular holes should also have sufficient bending strength. 3.

Rigid flexible combination board is a method of laminating a flexible circuit substrate and a rigid circuit substrate together, which has both the rigidity of a hard board and the flexibility of a soft board. So, what issues should be paid attention to when making rigid flexible composite boards? 1. The design of rigid flexible composite plates usually changes from rigidity to flexibility, and then to rigidity. The rigid region generally has more layers than the flexible region, and the material is transferred from FR-4 to polyimide in the transition region. When intersection occurs, the overlap between rigid and flexible materials needs to keep the holes away from the transition area to maintain integrity. In addition, many rigid and flexible designs incorporate reinforcing materials such as stainless steel or aluminum to provide additional support for connectors and components. 2. Flexible circuits have bent wires that can affect wiring. Due to possible material stress, it is n

Inquiry Now