+86 755 2794 4155

+86 755 2794 4155  sales@knownpcb.com

sales@knownpcb.com

-

Shenzhen KNOWNPCB Technology Co., Ltd.

+86 755 2794 4155

+86 755 2794 4155  sales@knownpcb.com

sales@knownpcb.com

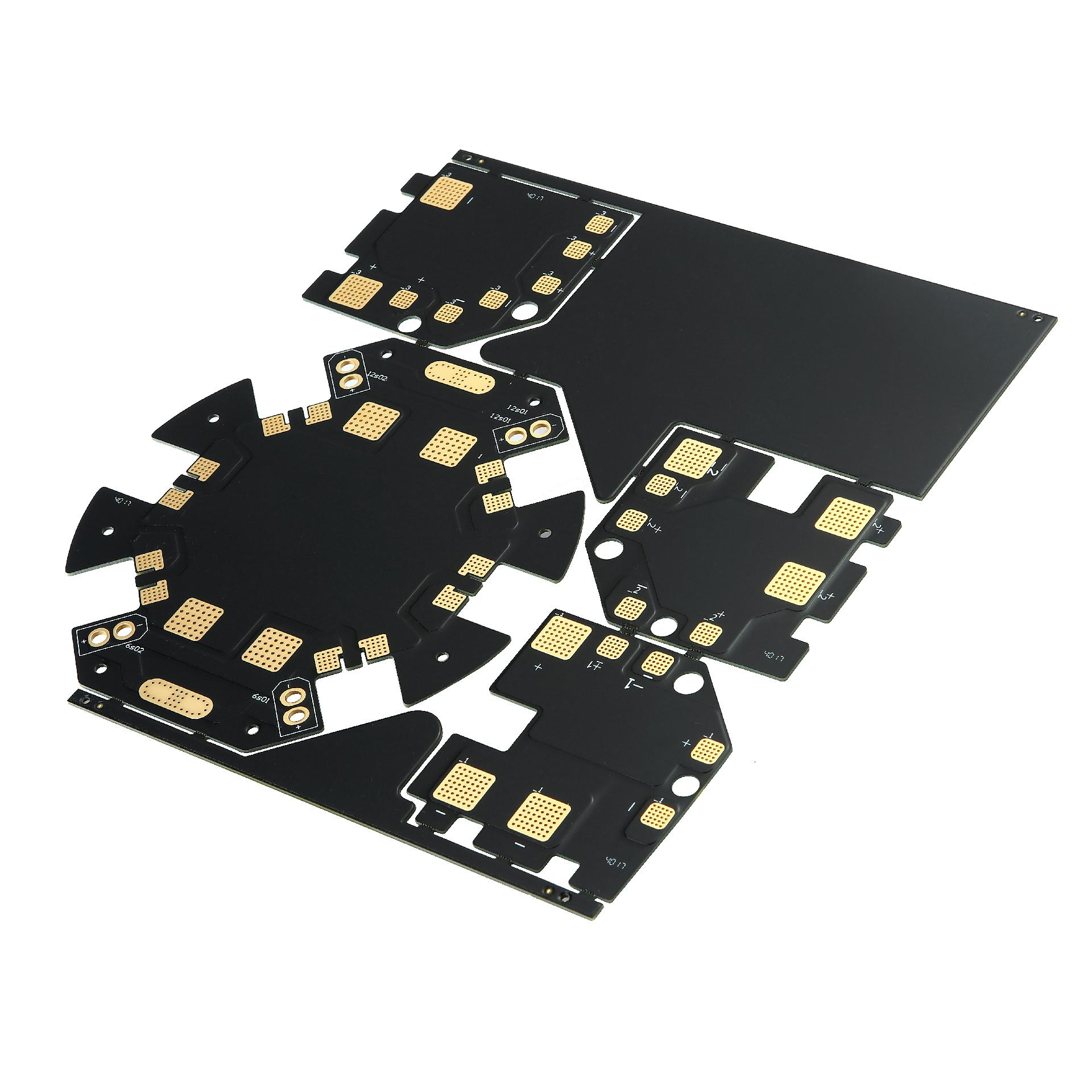

Have you noticed that now more and more of our lighting is using led lighting.What is LED? Compared to the traditional light bulbs, LEDs have lower power consumption, longer lifetime and higher energy efficiency. In the PCB industry,when we say LED PCB, it refers to the pcb used for LED lighting, if you are looking for a suitable LED PCB for your lighting system, this article may bring you something. WHAT ARE LEDS COMPOSED OF?LED is an initial light-emitting diode that produces light when an electric current passes through. LEDs typically have negative and positive electrodes, which generate light in the visible light region.The LEDS are glued to the PCB by soldering process and have electrical connections for lighting.Since light-emitting diodes dissipate a lot of heat when they are in use, when you are designing LED, the metal core is usually the best choice for LED PCB, it is because that it dissipates heat more faster. Among them, the metal material aluminum is the most widely used

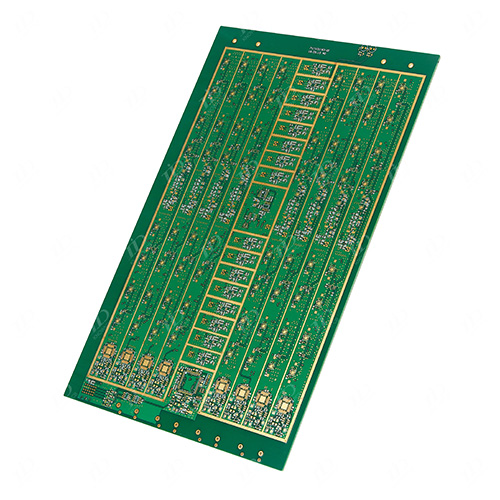

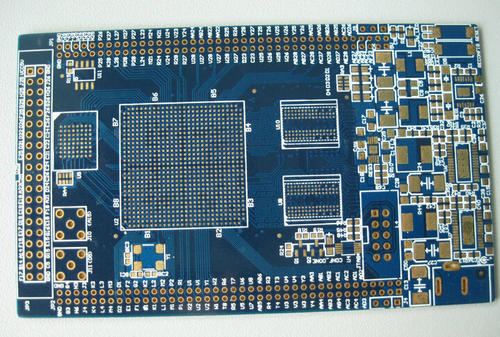

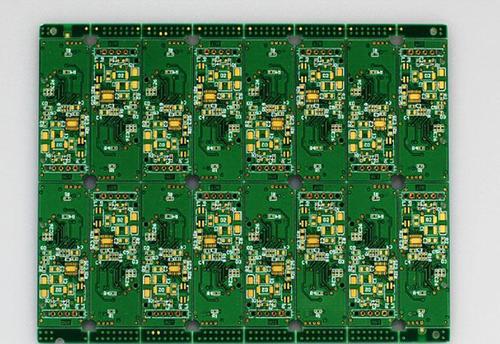

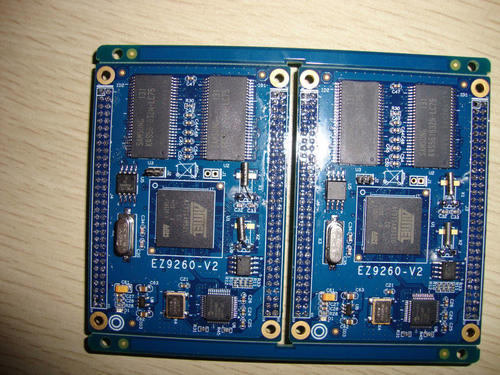

The general trend of industrial eastward movement, the mainland region outshines. The focus of the PCB industry continues to shift to the Asian region, and the capacity of the Asian region has further transferred to the mainland, forming a new industrial pattern. Applications such as data centers increase the demand for HDI, and the future space for FPC is broad. Data centers are developing towards the characteristics of high speed, large capacity, cloud computing, and high performance, and the construction demand is surging, among which the demand for servers will also pull up the overall demand for HDI. The popularity of mobile electronic products such as smartphones will also drive the demand for FPC boards. In the trend of intelligent and thin mobile electronic products, the advantages of light weight, thin thickness and bending resistance of FPC will be conducive to its wide application. The demand for FPC in the display module, touch module, fingerprint recognition module, sid

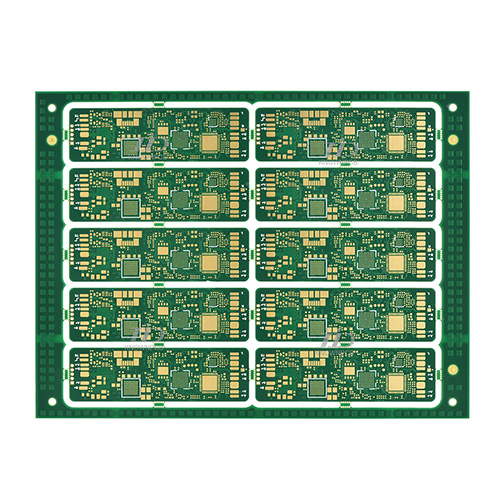

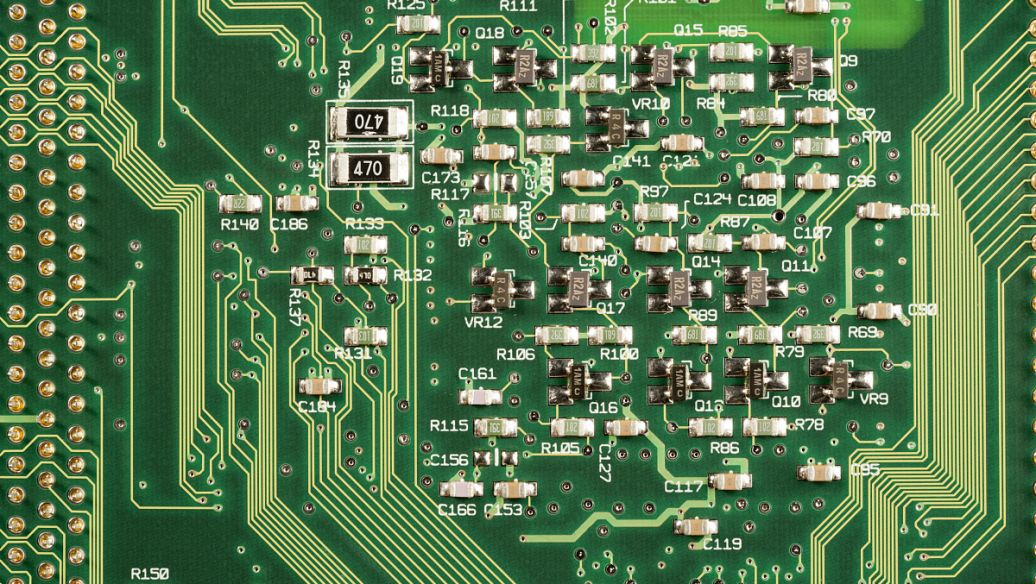

1) Single panel: This type of panel is usually used in the case of lower cost requirements. In layout design, sometimes components are needed or jumper wires are used to skip the circuit board's wiring. If there are too many, you should consider using dual panels. 2) Dual panel: Dual panel can be used or not to use PTH. Because PTH boards are expensive, they are only used when the complexity and density of the circuit require them. In general, the choice between a single panel or a dual panel must meet the most efficient cost utilization. As a rule of thumb, the cost of a double-sided printed board with plated through holes is 5-10 times that of a single panel. Similarly, the cost of assembling components is also an important aspect to consider, the cost of assembling a single-sided printed circuit board component (manual) is about 25%-50% of the cost of the circuit board, and the cost of assembling a double-sided printed circuit board component with PTH is 15%-30% of its cost.

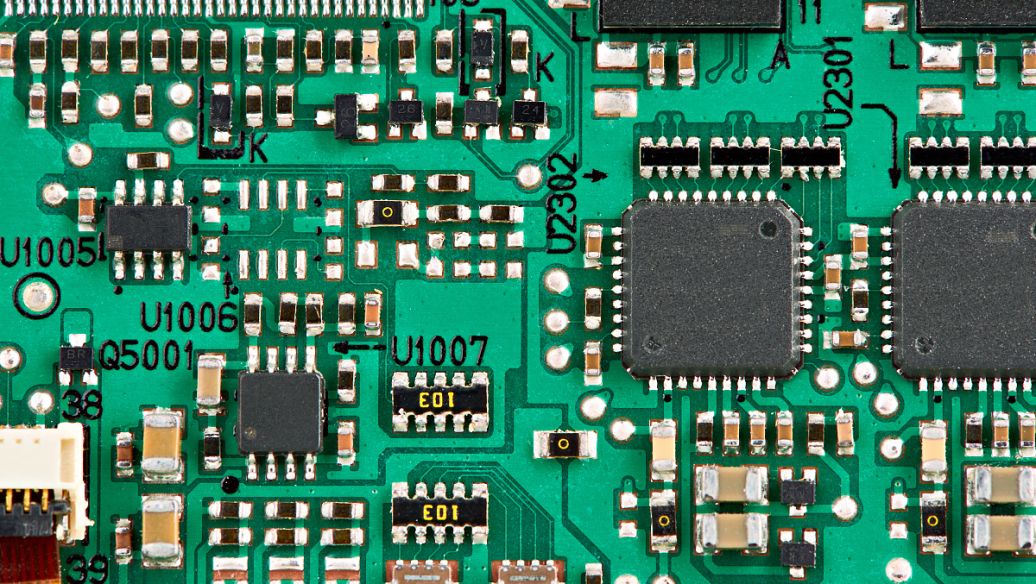

Automatic optical inspection (AOI) systems are commonly used to test the inner layer before the formation of layers. After stratification, X-ray systems monitor alignment accuracy and minor defects; A scanning laser system provides a way to detect the layer before reflow. These systems, along with line visual inspection technology and component integrity testing for automatically placed components, help ensure the reliability of the final assembly and welded plates. However, even if these efforts minimize defects, the final inspection of the assembled printed circuit board is still required, which is perhaps the most important, as it is the final unit for product and overall process evaluation. The final inspection of the assembled PCB board may be done by an active method or by an automated system, and often both methods are used together. Manual "means that an operator uses optical instruments to visually inspect the board and make a correct judgment about the gap. Automated sy

Automatic optical inspection (AOI) systems are commonly used to test the inner layer before the formation of layers. After stratification, X-ray systems monitor alignment accuracy and minor defects; A scanning laser system provides a way to detect the layer before reflow. These systems, along with line visual inspection technology and component integrity testing for automatically placed components, help ensure the reliability of the final assembly and welded plates. However, even if these efforts minimize defects, the final inspection of the assembled printed circuit board is still required, which is perhaps the most important, as it is the final unit for product and overall process evaluation. The final inspection of the assembled PCB board may be done by an active method or by an automated system, and often both methods are used together. Manual "means that an operator uses optical instruments to visually inspect the board and make a correct judgment about the gap. Automated sy

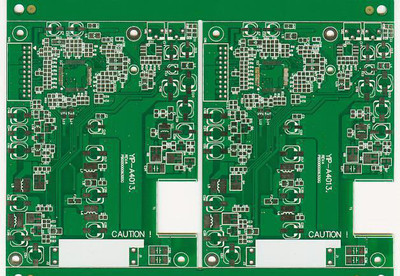

1, engineering design line width compensation: due to the thick copper, the line width must be compensated, otherwise the line width is too poor after etching, the customer is not accepted, the line width compensation value must experience stacking. 2, the uniformity of print resistance welding: due to the ultra-normal copper thickness of the line after graphic etching, print resistance welding is very difficult, skip printing, too thick and too thin customers do not bear. How to print this layer of green oil is also one of the difficulties. 3. Etching: The line width after etching must meet the needs of customer drawings. The residual copper is not allowed, nor can the knife be scraped away, the knife will scratch the insulation layer, resulting in sparks and leakage in the voltage test. 4, mechanical processing: aluminum substrate drilling can be, but the drilling hole inside the hole edge is not allowed to have any burrs, which will affect the pressure test. Milling shape is

1. It has the characteristics of small signal transmission loss, short transmission delay time and small signal transmission distortion. 2. Excellent dielectric properties (mainly: low relative dielectric constant Dk, low dielectric loss factor Df). Moreover, this dielectric property (Dk, Df) can maintain its stability under environmental changes in frequency, humidity, and temperature. 3. High precision control with characteristic impedance (Zo). 4. Excellent heat resistance (Tg), processability and adaptability. Based on the above characteristics, high-frequency PCB boards are widely used in wireless antennas, base station receiving antennas, power amplifiers, components (shitters, confluence, filters), radar systems, navigation systems and other communication equipment. Multi-layer high frequency plate design, based on cost savings, improving bending strength, electromagnetic interference control and other factors, often in the form of hybrid plate, called high frequency hy

1. Welding materials 1) The solder usually adopts Sn60 or Sn63 solder that meets the general standard of the United States, or adopts HL-SnPb39 type tin lead solder. 2) The flux can usually be rosin flux or water-soluble flux, the latter is generally only used for wave soldering. 3) The cleaning agent should ensure that the PCB board is non-corrosive and pollution-free, generally using anhydrous ethanol (industrial alcohol), trichlorotrifluoroethane, isopropanol (IPA), aviation washing gasoline and deionized water and other cleaning agents for cleaning. The specific cleaning agent used should be selected according to the process requirements. 2. Welding tools and equipment 1) The reasonable selection of the power and type of soldering iron has a direct relationship to improving welding quality and efficiency. It is recommended to use low-voltage temperature-controlled electric soldering iron, the soldering iron head can be nickel plated, iron plated or copper material, the sha

The minimum width of the printed wire is related to the size of the current flowing through the wire: the line width is too small, the resistance of the just-printed wire is large, the voltage drop on the line is large, affecting the performance of the circuit, the line width is too wide, the wiring density is not high, the board area increases, in addition to increasing the cost, it is not conducive to miniaturization. If the current load is calculated at 20A/ mm2, when the thickness of the copper clad foil is 0.5MM,(generally so much,) the current load of 1MM(about 40MIL) line width is 1A, Therefore, the line width of 1--2.54MM(40--100MIL) can meet the general application requirements, the ground wire and power supply on the high-power equipment board, according to the power size, can be appropriately increased line width, and in the low-power digital circuit, in order to improve the wiring density, the minimum line width of 0.254--1.27MM(10--15MIL) can be full Full. Same circui

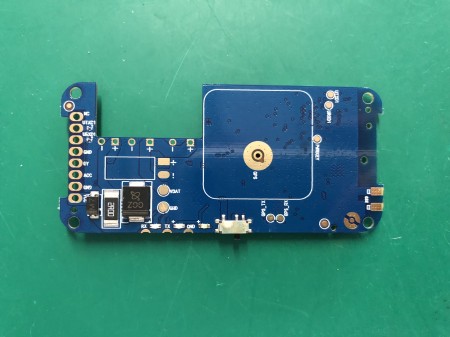

With the development of electronic products in the direction of "light, thin, short, and small", PCBs have also developed to high density and high difficulty. Therefore, a large number of SMT and BGA PCBs have appeared, and customers require plugging when mounting components, mainly including Five functions: (1) Prevent the tin from passing through the via hole to the component surface and cause a short circuit when the PCB is wave soldered; especially when we put the via on the BGA pad, we should first make the plug hole and then gold-plated, which is convenient for BGA welding. (2) Avoid flux residue in the via; (3) After the surface mounting and component assembly of the electronics factory are completed, the PCB must be vacuumed on the testing machine to form a negative pressure to complete: (four) to prevent surface solder paste from flowing into the hole, causing false soldering, affecting placement; (5) Prevent the solder balls from popping up during wave soldering, cau

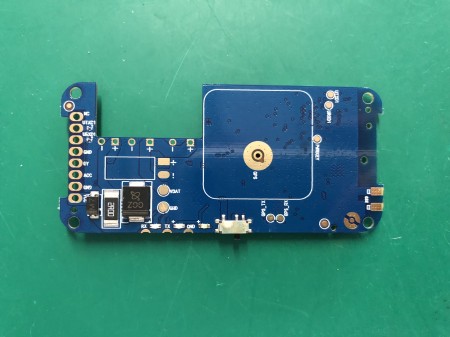

The high frequency board application such as 5G, routers, bluetooth headsets and other products that require fast signal transmission frequency. KnownPCB engaged in varies high frequency material, such as RO4003C, RO4350B,RO3006,RO5880....etc. The following is the DK value for reference. It is our big advantage in new material and high technology update.We can provide a variety of different types boards to meet your needs. No matter prototype 1pcs or mass production. Contact us now for further more info.

1) Double-head ultraviolet drilling system; 2) Double-head CO2 laser drilling system; 3) Hybrid laser drilling system (CO2 and UV). Such drilling systems in all HDI PCB board fabrication processes have their own advantages and disadvantages. Laser drilling systems can be simply divided into two types, two-bit single-wavelength systems and two-bit dual-wavelength systems. Regardless of the type, there are two main components that affect the ability to drill: 1) Laser energy/pulse energy; 2) Beam positioning system. The energy of the laser pulse and the transmission efficiency of the beam determine the drilling time, which refers to the time for the laser drilling machine to drill a micro-through hole, and the beam positioning system determines the speed of movement between the two holes. These factors together determine the laser drilling mechanism for the given requirements of the micro-hole speed. The dual-head UV laser system is best suited for drilling holes smalle

When we open the keyboard of a general-purpose computer, we see a soft film (flexible insulating substrate) printed with a silver-white (silver paste) conductive pattern and a health pattern. Because of the general screen printing method to obtain this pattern, we call this printed circuit board flexible silver paste printed circuit board. And we go to the computer city to see a variety of computer host board, graphics cards, network cards, modems, sound cards and household appliances on the printed circuit board is different. The substrate used is made of paper base (usually used for single side) or glass cloth base (often used for double side and multi-layer), pre-pregassed phenolic or epoxy resin, one or both surface layers are glued to a copper-coated sheet and then laminate and cure. This circuit board covered with copper sheet plate, we call it a rigid plate. Then made into a printed circuit board, we call it a rigid printed circuit board. Single-sided printed circuit graphic

1. Poor wear resistance, the wear resistance said here is not the wear resistance of metal materials, which refers to the PCB surface ink in use will often be worn off causing blurring, fading and so on. 2. Aesthetic requirements, the appearance of the metal surface printing feels relatively low-end, which is not suitable for some products with relatively high appearance requirements, such as commemorative badges, metal business cards, exquisite company promotional nameplates, handicraft description nameplates, etc., which cannot meet their appearance requirements. 3. Ordinary printing process requires the use of organic solvents and heavy metal elements and other chemical raw materials, these substances have certain toxicity and will cause personal injury to the screen printing staff, in addition, the drying process of screen printing ink, volatile chemical raw materials gradually volatilized into the air, causing pollution to the air and the environment. Compared with traditio

KnownPCB will attend Global Sourcing Electronics Exhibition in AsiaWorld-Expo,HongKong on Apr.11-14,2024.The address is at Asia Expo, Hongkong Asia expo, Booth No.: 11P12.We sincerely invite you to visit our Booth 11P12 in HK then.

Water-based cleaning process is based on water as the cleaning medium, in order to improve the cleaning effect, a small amount of surfactants, washing additives, corrosion inhibitors and other chemicals can be added to the water (the general content is 2%-10%). And can be in accordance with the specific situation of different nature of pollution on the printed circuit board, in the water-based cleaning agent additives, so that the scope of application of cleaning is wider. Water-based cleaning agent has a good dissolution effect on water-soluble dirt, and then with heating, brushing, spraying, ultrasonic cleaning and other physical cleaning means, can achieve better cleaning effect. The addition of surfactant to the water-based cleaning agent can greatly reduce the surface tension of water, strengthen the penetration and spreading ability of the water-based cleaning agent, and better penetrate into the gap between the closely arranged electronic components, and clean the dirt that

1. Dimensional stability of incoming substrate materials, especially the dimensional consistency between each laminating CYCLE of the supplier; Even if the dimensional stability of different cycles of the substrate of the same specification is within the specification requirements, due to the poor consistency between them, the graphic size of the subsequent mass production of the plate is out of line due to the difference between different batches of plate materials after the first plate trial production has determined a reasonable inner layer compensation. At the same time, there is a material anomaly that the board is found to shrink in the process of the outer pattern transfer to the shape process; In the production process, it was found that the width of the panel and the length of the shipping unit had a serious contraction in relation to the outer pattern transfer ratio during the pre-shape processing data measurement process, and the ratio reached 3.6mil/10inch. The specific

Step 1 Drill holes The design of the through hole aperture below 8mil, the hole spacing is close, plus each board about 500,000 to 1.2 million blind holes, the hole deviation and plugging of the through hole, and the perforation of the perforation will affect the PCB yield. Drilling machine needs to be maintained according to the regulations, the use of appropriate aluminum sheet and drill nozzle, in the production of new materials engineers to confirm the rationality of the operation parameters: number of sheets, tool parameters, etc. The amount of dust suction of the drilling machine needs to meet the standard, and the drilling needle has space for debris removal is also crucial. The pass shape and aperture, dielectric thickness, material and laser energy of the laser are very important, and it is necessary to set the best operating conditions. Step 2: Electroplating Electroplated copper carries the functions of current conduction and signal transmission, and the electroplating

Printed circuit board manufacturing industry more and more need high aspect ratio, small hole printed circuit board plating process. It is the driving force to promote the development of high-level multi-layer printed circuit board manufacturing technology. Because of the reliability of the hole coating, it plays a key role in the use of printed circuit boards. How to ensure the problem of high aspect ratio deep hole plating is the scientific and technological task of all printed circuit workers, and it is the most important problem that must be faced. To this end, many research departments began to carry out planned research and development. There are many methods reported from the current scientific and technological data, including pulse plating technology, chemical vapor deposition technology, solution impact plating technology, full electroless copper plating technology and improved (high acid and low copper) air stirring technology. This part of the technology is introduced a

1, in the case of mastering the operation technology of the digital programming instrument, first load the film and the drilling test plate, measure the length and width of the two deformation, in the digital programming instrument according to the size of the deformation of the hole to lengthen or shorten the hole, with the drilling test plate after lengthening or shortening the hole to match the deformed film, eliminating the tedious work of splicing the film, to ensure the integrity and accuracy of the graph. This method is called "changing hole position method". 2, in view of the physical phenomenon that the negative changes with the change of ambient temperature and humidity, the negative in the sealed bag is taken out before the copy of the negative, and the working environment conditions are hung for 4-8 hours, so that the negative is deformed before the copy, so that the deformation of the negative after the copy is very small, called this method "hanging method". 3. For

1. Splicing method: Applicable: The line is not too dense, the film deformation of each layer is inconsistent; It is especially suitable for the deformation of solder resistance plate and multilayer plate power formation plate. Not applicable: film with high wire density, line width and spacing less than 0.2mm; Note: When splicing, the wire should be damaged as little as possible, and the welding pad should not be damaged. When splicing copy after revision, attention should be paid to the correctness of the connection relationship. 2, change the hole position method: Application: All layers of film deformation is consistent. This method also applies to film with dense lines; Not applicable: film deformation is not uniform, local deformation is particularly serious. Note: After using the programmer to lengthen or shorten the hole position, the out-of-tolerance hole position should be reset. 3, hanging method: Applicable; Film that has not been deformed and is protected from

Inquiry Now