+86 755 2794 4155

+86 755 2794 4155  sales@knownpcb.com

sales@knownpcb.com

-

Shenzhen KNOWNPCB Technology Co., Ltd.

+86 755 2794 4155

+86 755 2794 4155  sales@knownpcb.com

sales@knownpcb.com

Have you noticed that now more and more of our lighting is using led lighting.What is LED? Compared to the traditional light bulbs, LEDs have lower power consumption, longer lifetime and higher energy efficiency. In the PCB industry,when we say LED PCB, it refers to the pcb used for LED lighting, if you are looking for a suitable LED PCB for your lighting system, this article may bring you something. WHAT ARE LEDS COMPOSED OF?LED is an initial light-emitting diode that produces light when an electric current passes through. LEDs typically have negative and positive electrodes, which generate light in the visible light region.The LEDS are glued to the PCB by soldering process and have electrical connections for lighting.Since light-emitting diodes dissipate a lot of heat when they are in use, when you are designing LED, the metal core is usually the best choice for LED PCB, it is because that it dissipates heat more faster. Among them, the metal material aluminum is the most widely used

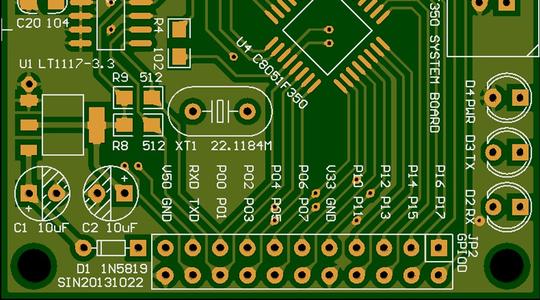

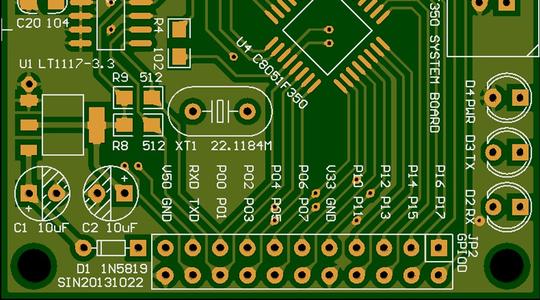

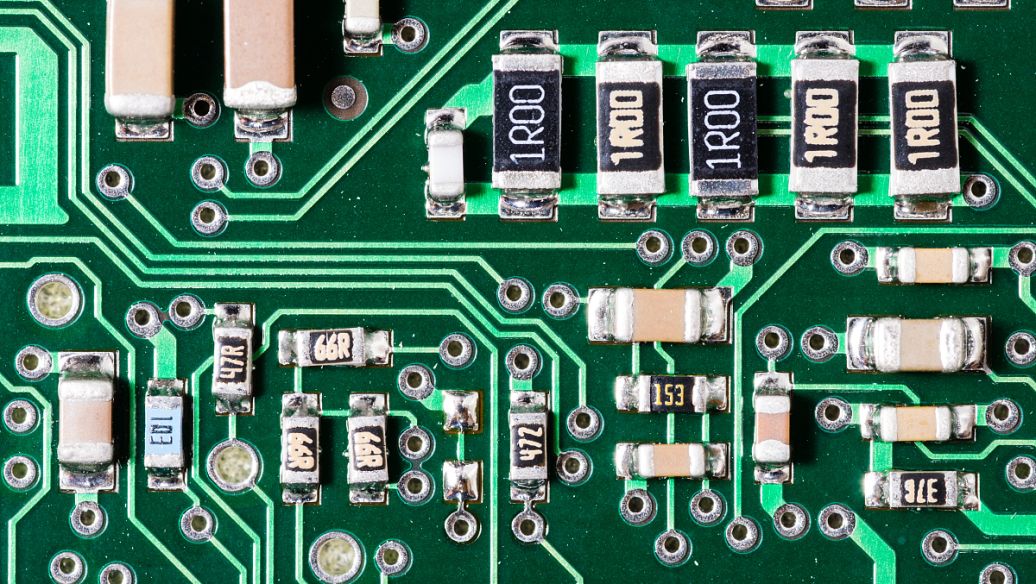

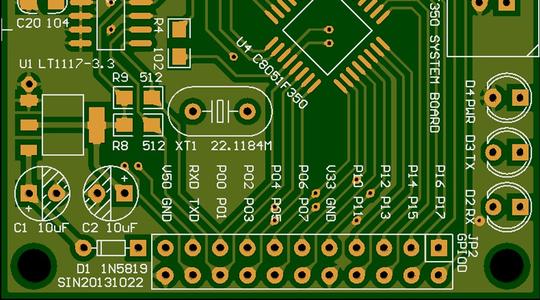

Printed circuit boards (PCBs) are an indispensable part of modern electronic devices, and copper plays a crucial role in them. Copper circuit board, as the name suggests, is a circuit board that uses copper as a conductive material. Copper, due to its excellent conductivity and ductility, has become an ideal choice for making circuit boards. During the manufacturing process, copper is plated on a substrate and then circuit patterns are formed through photolithography and etching processes. These copper wires are responsible for connecting various electronic components, allowing the current to flow smoothly. The high conductivity of copper means that circuit boards can achieve efficient electrical connections in a small space, thereby reducing resistance and energy loss. In addition, copper also has good corrosion resistance and oxidation resistance, which enables copper circuit boards to maintain stable performance in various harsh environments. Copper can ensure the long-term re

Copper plated circuit board is a circuit board that is coated with a layer of copper on a substrate to form a circuit pattern. Copper plating process is one of the key steps in manufacturing PCBs, which forms fine circuit patterns on the substrate to achieve electrical connections between electronic components. In the copper plating process, electroplating or chemical plating methods are usually used. Electroplating is the process of depositing copper ions onto a substrate through an electrolytic cell, while chemical plating utilizes chemical reactions to form a copper layer on the surface of the substrate. Regardless of the method, precise control of process parameters is required to ensure the uniformity of the copper layer and the accuracy of the circuit. Copper plated circuit boards are widely used in various electronic devices, including computers, communication equipment, consumer electronics products, and automotive electronic systems. Its superior conductivity and mechani

Copper clad circuit boards, as an indispensable basic material in modern electronic industry, are widely used in various electronic and communication equipment. Copper clad circuit board, as the name suggests, is a circuit board made by covering a layer of copper foil on the substrate and using a series of processes such as etching, drilling, and copper plating. It is not only the support for electronic components, but also the carrier for electrical connections of electronic components. The main materials of copper-clad circuit boards include substrates, copper foil, and adhesives. The substrate is usually made of glass fiber reinforced epoxy resin board, which has good insulation and heat resistance. Copper foil is used as a conductive material to create circuit patterns. Adhesive is used to bond copper foil and substrate together, ensuring the mechanical strength and electrical performance of the circuit board. The key performance indicators of copper-clad circuit boards inclu

Copper circuit boards, with their excellent conductivity and mechanical properties, have become an indispensable basic material in modern electronic industry. Copper circuit boards are widely used in various electronic and communication devices, playing an important role in supporting electronic components and achieving electrical connections. The main materials of copper circuit boards include copper foil, substrate, and adhesive. Copper foil, as a conductive material, is used to make circuit patterns. The substrate serves as the support body and is usually made of glass fiber reinforced epoxy resin board, which has good insulation and heat resistance. Adhesive is used to bond copper foil and substrate together, ensuring the mechanical strength and electrical performance of the circuit board. The key performance indicators of copper circuit boards include heat resistance, chemical resistance, dielectric constant, and mechanical strength. These indicators directly affect the reli

Printed Circuit Board (PCB), as the core component of modern electronic devices, is almost ubiquitous. From smartphones and tablets to cars and household appliances, PCBs play a crucial role in various fields. It not only carries various electronic components, but also is responsible for the electrical connection between them to ensure the normal operation of the equipment. The basic structure of copper-clad circuit boards consists of one or more copper foil layers and non-conductive substrates. The copper foil layer forms complex circuit patterns through etching technology, including wires, solder pads, and through holes. Non conductive substrates typically use glass fiber, epoxy resin, or other composite materials to provide mechanical support and insulation performance. As needed, PCBs can be designed as single-layer, double-layer, or multi-layer structures to meet the functional requirements and space limitations of different electronic devices. During the manufacturing proce

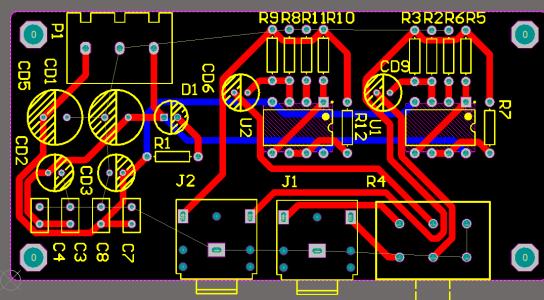

Copper circuit boards mainly consist of the following parts: 1. Substrate: usually fiberglass cloth impregnated with epoxy resin or other synthetic resins to form a hard composite material. 2. Copper foil: A thin layer of copper covering the surface of the substrate, typically ranging in thickness from a few micrometers to tens of micrometers. 3. Circuit pattern: A conductive path formed on copper foil through processes such as etching and electroplating, used to connect various electronic components. The process of manufacturing copper circuit boards mainly includes the following steps: 1. Design and plate making: Use computer-aided design (CAD) software to design circuit patterns and create photo plates. 2. Lamination: The copper foil and substrate are bonded together by hot pressing. 3. Exposure and development: Use photosensitive resin and photoresist to expose and develop, forming a mask for circuit patterns. 4. Etching: By chemical etching or laser cutting, unwanted c

In modern electronic devices, printed circuit boards (PCBs) play a crucial role as core components. Copper clad PCB materials, with their excellent conductivity and reliability, have become the preferred choice for many high-performance applications. Copper clad PCB material refers to the process of covering a substrate with a layer of copper foil and forming circuit patterns through etching. The excellent conductivity and thermal conductivity of copper make it an ideal material for making circuit boards. Whether used in high-speed communication equipment, high-performance computing, or precision measurement instruments, copper clad PCB materials can provide stable and efficient current transmission, ensuring the normal operation of the equipment. Our copper clad PCB materials use high-quality raw materials and advanced production processes to ensure that each circuit board meets the highest standards. We offer copper foil of various thicknesses and specifications to meet the nee

In modern electronic devices, copper-clad circuit boards (PCBs) play a crucial role as core components. Copper clad PCB boards, with their excellent conductivity and reliability, have become the preferred choice for many electronic devices. Copper clad PCB board, as the name suggests, is a circuit pattern formed by covering a layer of copper foil on the substrate through an etching process. The excellent conductivity and thermal conductivity of copper make it an ideal material for making circuit boards. Whether used in computers, communication equipment, or consumer electronics, copper clad PCB boards can provide stable and efficient current transmission, ensuring the normal operation of equipment. Our copper clad PCB boards use high-quality raw materials and advanced production processes to ensure that each circuit board meets the highest standards. We offer copper foil of various thicknesses and specifications to meet the needs of different customers. Whether it's single-layer

In modern electronic devices, copper printed circuit boards (PCBs) play a crucial role. It is not only the carrier of various electronic components, but also the bridge connecting them to each other. Copper printed circuit boards have become an indispensable core component in electronic products due to their excellent conductivity and stable mechanical properties. Our copper printed circuit boards use high-quality copper materials and advanced production processes to ensure that each circuit board has excellent electrical performance and a long service life. Whether it's single-layer board, double-layer board, or multi-layer board, we can provide the most suitable solution according to customer needs. Our circuit boards undergo strict quality control and testing to ensure stable operation in various harsh environments. To meet the needs of different customers, we provide a variety of customized services, including circuit design, component soldering, and functional testing. Wheth

In modern industrial production, composite panels, as a multifunctional material, are widely used in various fields. It combines materials with different properties to form a new type of material that combines multiple characteristics. Composite panels not only have high strength and good corrosion resistance, but also excellent conductivity and stability, making them an ideal choice in the fields of electronic products, aerospace, and architectural decoration. Our composite panels use advanced production processes and high-quality raw materials to ensure that each panel has excellent performance and a long service life. Whether it's metal composite panels, non-metallic composite panels, or hybrid composite panels, we can provide the most suitable solutions according to customer needs. Our composite panels undergo strict quality control and testing to ensure stable operation in various harsh environments. To meet the needs of different customers, we provide a variety of customize

In modern industrial production, composite panels, as a multifunctional material, are widely used in various fields. It combines materials with different properties to form a new type of material that combines multiple characteristics. Composite panels not only have high strength and good corrosion resistance, but also excellent conductivity and stability, making them an ideal choice in the fields of electronic products, aerospace, and architectural decoration. Our composite panels use advanced production processes and high-quality raw materials to ensure that each panel has excellent performance and a long service life. Whether it's metal composite panels, non-metallic composite panels, or hybrid composite panels, we can provide the most suitable solutions according to customer needs. Our composite panels undergo strict quality control and testing to ensure stable operation in various harsh environments. To meet the needs of different customers, we provide a variety of customize

Printed Circuit Board (PCB) is one of the essential core components in modern electronic devices. It achieves electrical connections and signal transmission between electronic components by etching fine copper wires on insulating substrates. Copper printed boards are widely used in various fields such as computers, communication equipment, consumer electronics, and medical instruments, playing a crucial role. Firstly, copper printed boards have excellent conductivity and stable chemical properties. The low resistance and high thermal conductivity of copper make it an ideal material for making circuit boards. By coating a thin layer of copper foil on the substrate, followed by a series of processes such as exposure, development, and etching, complex circuit patterns are formed to ensure the efficient operation and heat dissipation requirements of electronic devices. Secondly, copperplate printing has a high degree of integration and flexibility. Modern electronic products pursue m

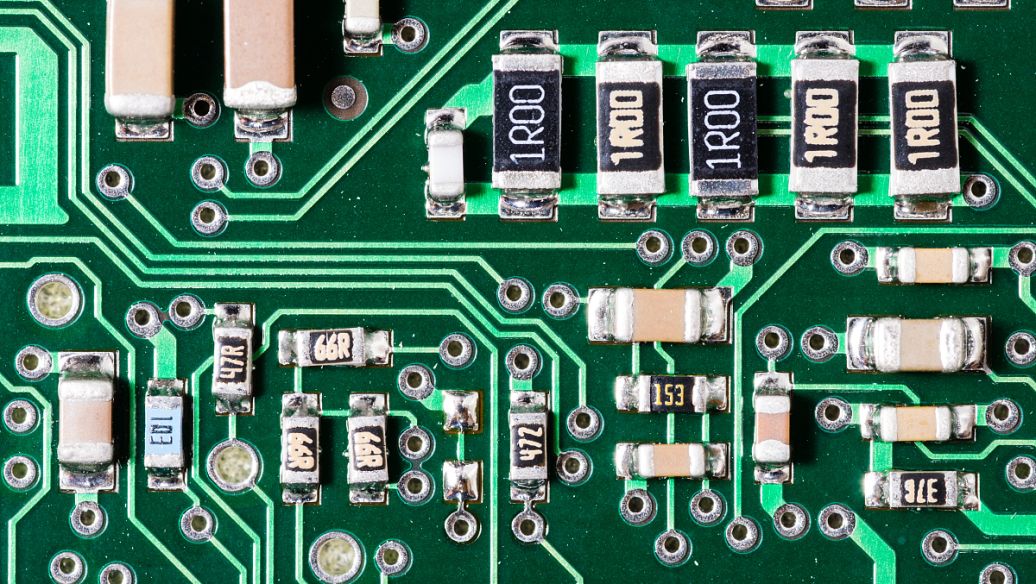

1、 The materials used for PCB circuit boards are different Taking ordinary double-sided boards as an example, the board materials generally include FR-4, CEM-3, etc. The board thickness ranges from 0.6mm to 3.0mm, and the copper thickness ranges from? Oz to 3 Oz are different. In terms of solder mask ink, there is also a certain price difference between ordinary thermosetting oil and photosensitive green oil. 2、 Different production processes are used for PCBs Different production processes will result in different costs. Products such as gold-plated plates and spray tin plates, as well as gongs (milled) and beer (punched) plates used for shape production, and the use of silk screen and dry film circuits will result in different costs. 3、 The difficulty of PCB circuit boards themselves varies Even if the materials are the same and the processes are the same, the difficulty of the PCB itself will result in different costs. If there are 1000 holes on both types of circuit boards

In almost all electronic products, printed circuit boards (PCBs) are an indispensable core component, known as the heart of electronic products. The performance and quality of PCBs directly affect the reliability, operational efficiency, and service life of electronic devices. Firstly, PCB provides a physical platform for all components in electronic devices, ensuring efficient flow of current between different components through precise layout and design, thereby ensuring the normal operation of the equipment. Secondly, as electronic products develop towards smaller, lighter, and thinner directions, PCBs are also constantly evolving. High density interconnect (HDI) technology and multi-layer board design enable more electronic components to be integrated into smaller spaces, meeting the needs of miniaturization. Once again, the design and manufacturing process of PCBs require high precision and rigorous quality control. Excellent PCB design can reduce electromagnetic interferen

Printed Circuit Board (PCB) is a bridge connecting the electronic world. Through precise circuit and interface design, various components in electronic devices can work together to create a rich and colorful digital life. Firstly, the basic function of a PCB is to provide a platform for electronic signals to flow and exchange between different components. On this platform, numerous components such as microprocessors, memory, sensors, etc. can communicate and collaborate through predefined paths. Secondly, with the diversification and complexity of electronic devices, PCB design has become increasingly complex. From simple single-layer boards to complex multi-layer boards, and even three-dimensional packaging, the design and manufacturing technology of PCBs has been constantly improving. Once again, with the development of emerging technologies such as the Internet of Things, artificial intelligence, and 5G, the PCB industry is facing new challenges and opportunities. The progres

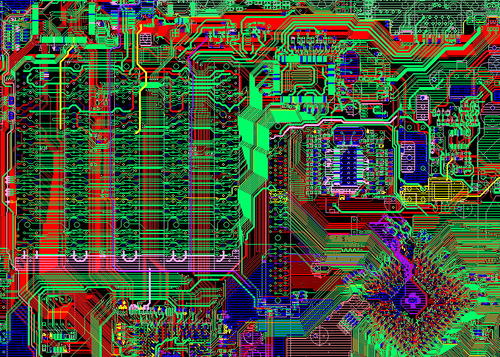

Copper coating refers to using the idle space on the PCB as a reference plane and then filling it with solid copper. These copper areas are also known as copper filling. The significance of copper plating is to reduce the impedance of the ground wire and improve its anti-interference ability; Reduce voltage drop and improve power efficiency; Also, connect to the ground wire to reduce the loop area. If there is a lot of ground on a PCB, such as SGND, AGND, GND, etc., how to cover it with copper? My approach is to use the most important "ground" as a reference for independent copper plating based on the different positions of the PCB board, and to separate the digital and analog copper plating without much explanation. Before copper plating, first thicken the corresponding power lines: V5.0V, V3.6V, V3.3V (SD card power supply), and so on. In this way, multiple deformation structures with different shapes are formed. There are several issues that need to be addressed in copper plati

PCB surfaces are generally coated with a layer of paint to protect the metal, and the paint should be removed before recycling. There are two types of paint removers: organic paint removers and alkaline paint removers. Organic paint removers have high toxicity and pose great harm to human health and the environment, while alkaline paint removers have relatively low toxicity. We obtained the optimal formula for paint removal through experiments: place the cut PCB chips into a 10% sodium hydroxide solution. Adding 0.5% additive A, 0.5% additive B, and 0.05% corrosion inhibitor mercaptobenzotriazole, heating in a water bath can completely remove the surface paint within 30 minutes, further recovering the exposed metal. Alkaline paint stripping is the separation of paint from the contact area of the circuit board. The paint mainly exists in its original structure and can be recycled.

Physical methods for PCB recycling and processing The physical method involves recycling based on differences in physical properties such as material density, conductivity, magnetism, and surface wettability. The main processes include disassembly, crushing, sorting, recovery of precious metals, and treatment of harmful substances. (1) The general order of selective dismantling of electronic waste is to select reusable parts. Disassemble harmful components and classify parts of various materials. The disassembly methods include manual disassembly, mechanical disassembly, and automatic disassembly. The automatic disassembly of PCBs uses methods such as bath washing or hot air heating to dissolve solder, and then uses vacuum clamps or robots to remove surface components of PCBs. (2) Broken. The crushing of PCB includes impact crushing, extrusion crushing, and shear crushing. The most successful application currently is the ultra-low temperature freezing crushing technology, which ca

1. There are various problems that occur during the PCB manufacturing process, and process engineers often take on the responsibility of forensic autopsy (analysis of the causes of defects and solutions). The main purpose is to discuss the potential issues that may arise in terms of personnel, machinery, materials, and conditions in the equipment area one by one. We hope that everyone can participate and provide their own opinions and opinions. 2. Processes that use pre-treatment equipment, such as inner pre-treatment lines, electroplating copper pre-treatment lines, D/F, solder mask (solder mask) Wait a minute. 3. Taking the pre-treatment line for solder resistance (solder mask) of hard board PCB as an example (different manufacturers may have differences): brush grinding * 2 groups ->water washing ->acid washing ->water washing ->cold air knife ->drying section ->sun disk collection ->discharge collection. 4. Generally, steel brushes with brush wheels of # 600 and # 800 are us

Symptoms: Poor adhesion of printing materials, poor adhesion of coatings, inability to etch off certain parts, and inability to solder certain parts. Possible inspection methods: Visual inspection is usually performed by forming visible water marks on the surface of the board: Possible reason: Due to the extremely dense and smooth surface caused by the demolding film, the uncoated copper surface becomes excessively bright. Usually, on the uncoated side of the laminate, the laminate manufacturer does not remove the release agent. The pinholes on the copper foil cause resin to flow out and accumulate on the surface of the copper foil, which usually occurs on copper foils thinner than 3/4 ounce weight specifications. Copper foil manufacturers apply excess antioxidants to the surface of copper foil. The manufacturer of the laminated board has changed the resin system, demoulding thin, or brushing method. Due to improper operation, there are many fingerprints or oil stains. Stain eng

Inquiry Now