+86 755 2794 4155

+86 755 2794 4155  sales@knownpcb.com

sales@knownpcb.com

-

Shenzhen KNOWNPCB Technology Co., Ltd.

+86 755 2794 4155

+86 755 2794 4155  sales@knownpcb.com

sales@knownpcb.com

Have you noticed that now more and more of our lighting is using led lighting.What is LED? Compared to the traditional light bulbs, LEDs have lower power consumption, longer lifetime and higher energy efficiency. In the PCB industry,when we say LED PCB, it refers to the pcb used for LED lighting, if you are looking for a suitable LED PCB for your lighting system, this article may bring you something. WHAT ARE LEDS COMPOSED OF?LED is an initial light-emitting diode that produces light when an electric current passes through. LEDs typically have negative and positive electrodes, which generate light in the visible light region.The LEDS are glued to the PCB by soldering process and have electrical connections for lighting.Since light-emitting diodes dissipate a lot of heat when they are in use, when you are designing LED, the metal core is usually the best choice for LED PCB, it is because that it dissipates heat more faster. Among them, the metal material aluminum is the most widely used

The assembly of electronic products poses significant challenges to production scheduling due to the large number and variety of components, as well as the short lifespan of electronic products. Multi variety, small batch, and variable batch production have become the mainstream production mode in electronic manufacturing. In this mode, the switching time between multiple varieties occupies an increasingly large proportion of the entire assembly time. Composed of a high-speed SMT machine and a multifunctional SMT machine. In fact, the entire PCB assembly line also includes equipment such as feeding machines, screen printing machines, dispensing machines, reflow soldering and curing furnaces, and take-up machines. These devices are connected in series to form the PCB assembly line, but these auxiliary devices do not constitute the bottleneck process of the entire assembly line, so they are omitted during modeling. Each SMT machine can accommodate 20 feeding slots, and each componen

The purpose of tin plating on PCB circuit boards is to prevent bare copper from reacting directly with oxygen in the air, causing oxidation of the board surface. In addition, tin plating is also helpful for PCBA surface mounting, which can be directly melted and used for plug-in, accelerating welding efficiency. So what is the reason for the PCB circuit board not being soldered? Let's take a look below. There are several reasons why PCB boards are not soldered: 1. PCB circuit board oxidation, PCB board not tin coated. 2. The temperature of the furnace is too low or the speed is too fast, and the tin has not melted. 3. If there is a solder paste issue, you can try changing to another type of solder paste. 4. The most common issue with battery cells is that they are usually made of stainless steel and require electroplating with a layer of chromium before tin can be applied. If there is oil or poor electroplating on this electroplating layer, it may not be able to solder. You ca

It is generally believed that if the frequency of a digital logic circuit reaches or exceeds 45MHz~50MHz, and the circuit operating above this frequency already occupies a certain proportion of the entire electronic system (such as 1/3), it is called a high-speed circuit. In fact, the harmonic frequency at the edge of the signal is higher than the frequency of the signal itself, which is an unexpected result of signal transmission caused by the rapid changes in the rising and falling edges (also known as signal jumps) of the signal. Therefore, it is generally agreed that if the line propagation delay is greater than 1/2 of the rise time of the digital signal driver end, such signals are considered high-speed signals and generate transmission line effects. The transmission of signals occurs at the moment when the signal state changes, such as the rise or fall time. The signal passes through a fixed period of time from the driving end to the receiving end. If the transmissio

Principle 1: Look first, measure later The circuit board to be repaired should first be visually inspected. If necessary, a magnifying glass should also be used for observation. Mainly looking at: 1. Are there any broken wires or short circuits; Especially whether there is any breakage or adhesion in the connecting wires of the printed circuit board; 2. Whether there is disconnection phenomenon in relevant components such as resistors, capacitors, inductors, diodes, and transistors; Has anyone repaired it? What components have been touched? Is there any problem of virtual welding, missing welding, reverse insertion, or incorrect insertion. After ruling out the above conditions, first use a multimeter to measure the resistance value between the power supply and ground of the circuit board. Generally, the resistance value of the circuit board should not be less than 70 Ω. If the resistance value is too small, it is only a few or ten ohms. This indicates that there are component

(1) Pre drying The purpose of pre drying is to evaporate the solvent contained in the ink and make the solder mask non stick. The pre drying temperature and time vary depending on the type of ink. Excessive pre drying temperature or prolonged drying time can lead to poor development and reduced resolution; If the pre drying time is too short or the temperature is too low, the film will adhere during exposure. During development, the solder mask film will be corroded by sodium carbonate solution, causing the surface to lose luster or the solder mask film to expand and fall off. (2) Exposure Exposure is the key to the entire process. For positive images, when overexposed, due to light scattering, the solder mask at the edges of the pattern or line reacts with light (mainly the photosensitive polymers contained in the solder mask react with light), generating residual film and reducing the resolution, resulting in a smaller developed pattern and thinner lines; If exposed When insu

1. Film negatives should not have problems such as trachoma or scratches. When placing, the film surface should be facing upwards and should not rub against other objects. When copying, the film surface should be operated on. After use, it should be promptly placed in a suitable film bag for storage. 2. When aligning, the film should be facing the board. When taking the film, use both hands to pick it up diagonally and avoid touching other objects to avoid scratching the film surface. When each film reaches a certain number of boards, stop aligning and have a dedicated person inspect or replace it. After use, put it in a suitable film bag for storage. 3. Operators are not allowed to wear any decorations such as rings, bracelets, etc. on their hands. Nails should be regularly trimmed and kept smooth, and no debris should be placed on the surface of the counter. The countertop should be kept clean and smooth. 4. Before production, it is necessary to strictly inspect the screen to

a、 According to the mechanical rigidity of copper-clad laminates, they are divided into rigid copper-clad laminates and flexible copper-clad laminates; b、 According to the insulation material and structure of copper clad laminates, they are divided into organic resin based copper clad laminates, metal based copper clad laminates, and ceramic based copper clad laminates; c、 According to the thickness of the copper clad plate, it is divided into thick plate (with a thickness range of 0.8-3.2mm (including Cu)) and thin plate (with a thickness range of less than 0.78mm (excluding Cu)); d、 According to the reinforcing materials of copper clad laminates, they are divided into glass cloth based copper clad laminates, paper based copper clad laminates, and composite based copper clad laminates (CME-1, CME-2). e、 Divided into flame retardant board and non flame retardant board according to flame retardant level. f、 According to certain properties of copper-clad laminates, they are divi

Circuit components: In order to improve the functionality of printed boards, there are now more and more printed components. In high-frequency digital circuits, wires are transmission lines with impedance requirements and are not simply conductive. There are also inductors, resistors, capacitors, etc. printed on the board surface or buried inside the board. (2) Reliability: withstands certain environmental conditions and has a certain service life. Environmental conditions: The product will definitely be used under certain temperature, humidity, air pressure, and environmental gas conditions. The indoor temperature of the TV, the gas in the refrigerator and kitchen, the electronic instruments of the car are exposed to ice and snow (negative 45 degrees Celsius) and the scorching heat of the desert (positive 60 degrees Celsius), and the communication equipment of the ship is affected by dampness and salt mist in harsh weather conditions. Printed boards may be subjected to these env

To exceed the limits of the extreme working conditions listed in the manual. All idle inputs on the device must be connected to VDD or VSS and have good contact. All low impedance devices (such as pulse signal generators, etc.) are connected to CMOS or NMOS integrated circuit inputs All MOS integrated circuits (including P-channel MOS, N-channel MOS, complementary MOS-CMOS integrated circuits) have an insulating gate to prevent voltage breakdown. The thickness of the insulation gate oxide layer in general devices is approximately 25nm, 50nm, and 80nm. In front of the high impedance gate of the integrated circuit, there is a resistor diode network for protection. However, the protection network inside the device is not sufficient to avoid electrostatic damage (ESD) to the device. Experiments have shown that the device will fail during high voltage discharge, and the device may also fail due to the accumulation of multiple lower voltage discharges. There are various forms of electr

1. There are various problems that occur in the PCB process, and process engineers often take on the responsibility of forensic autopsy (analysis of the causes of defects and solutions) Therefore, the main purpose of initiating this discussion question is to discuss one by one in the equipment area, including personnel, machinery, materials, and possible problems that may arise under certain conditions 2. Processes that use pre-treatment equipment, such as inner pre-treatment lines, electroplating copper pre-treatment lines, D/F, solder mask (solder mask) Wait a minute 3. Taking the pre-treatment line for solder mask (solder mask) on hard board PCB as an example (different manufacturers may have differences): brush grinding * 2 groups ->water washing ->acid washing ->water washing ->cold air knife ->drying section ->sun disk collection ->discharge collection 4. Generally, steel brushes with brush wheels of # 600 and # 800 are used, which can affect the roughness of the board sur

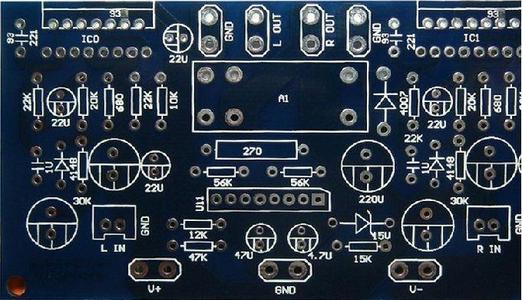

The first step is to obtain a PCB, and first record the models, parameters, and positions of all the components on paper, especially the direction of diodes, transistors, and IC notches. It is best to take two photos of the position of the pneumatic components with a digital camera; Step 2, remove all components and remove the tin from the PAD holes. Clean the PCB with alcohol, then put it into the scanner, start POHTOSHOP, scan the silk screen surface in color, and print it out for later use; Step three, use gauze paper to lightly polish the top layer and bottom layer until the copper film is shiny. Place them in the scanner, start Photoshop, and scan the two layers in color. Note that the PCB must be placed horizontally and straight in the scanner, otherwise the scanned image cannot be used. Please select a scanner resolution of 600; Step four, adjust the contrast and brightness of the canvas to make the parts with and without copper film more contrasting. Then, turn the secon

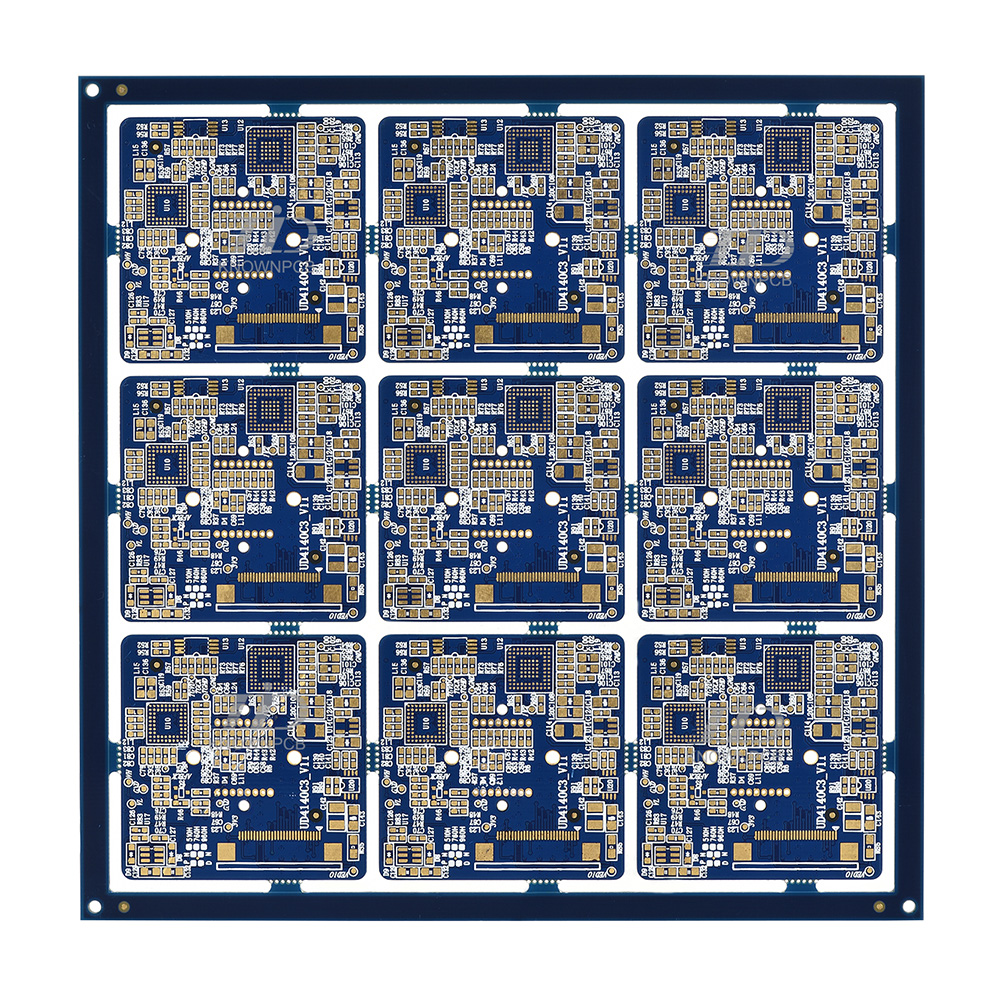

The original size of the copper-clad board is too large, making it inconvenient to process. Sometimes, it cannot even be placed in the printed circuit board processing equipment for processing. Therefore, it is necessary to first cut it into several copper-clad boards of different processing sizes. As for the specific size of the processing size, it needs to be determined based on the processing equipment for producing printed circuit boards, the size of each printed circuit board, and some process parameters. These process parameters not only include the length and width required for the printed circuit graphics themselves, but also the width consumed for fixing the screw holes on the printed circuit board to the electronic product frame, the process allowance for external processing, the clamping allowance for fixtures during chemical plating, electroplating, and corrosion, the positioning pin allowance for multi-layer printed circuit boards, the alignment mark allowance between

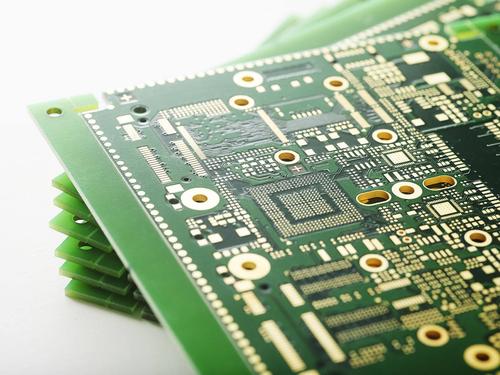

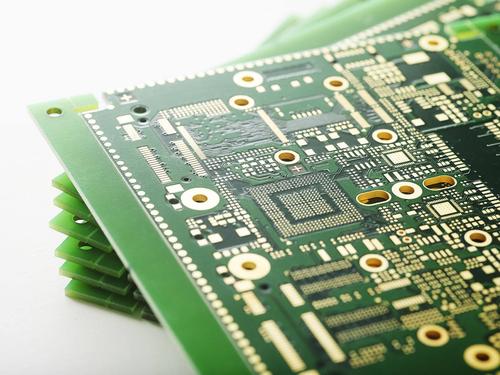

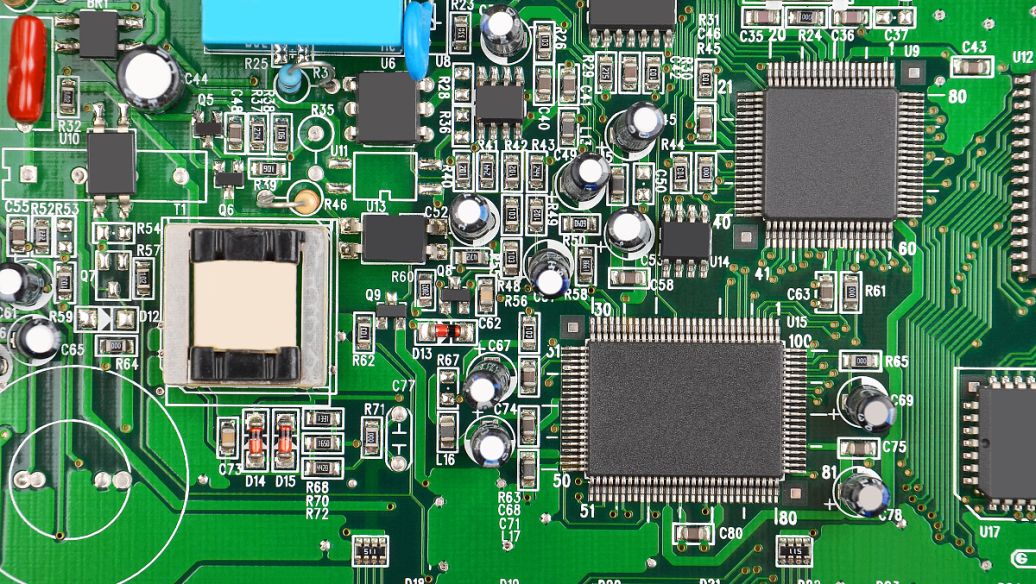

1. The assembly density of multi-layer circuit boards is high and their volume is small. With the decreasing volume of electronic products, higher requirements are also put forward for the electrical performance of PCBs, and the demand for multi-layer circuit boards is also increasing. 2. The use of multi-layer circuit boards facilitates wiring, significantly shortens the length of wiring, and shortens the connections between electronic components, which also improves the speed of signal transmission. 3. For high-frequency circuits, after adding a ground layer, the signal line will form a constant low impedance to the ground, resulting in a significant reduction in circuit impedance and better shielding effect. 4. For electronic products with high heat dissipation requirements, multi-layer circuit boards can be equipped with metal core heat dissipation layers, which is convenient to meet special functional needs such as shielding and heat dissipation. In terms of performance, m

1. Drilling parameters: The setting of drilling parameters is crucial. If the drilling speed is too fast, the drilling nozzle will break due to excessive force, and if the drilling speed is too slow, it will reduce production efficiency. Due to differences in the thickness, copper thickness, and material structure of PCB boards produced by various board manufacturers, PCBs need to be set according to specific circumstances. Select the most suitable drilling parameters through calculation and testing. Generally, for a 0.3mm drill bit, the cutting speed should be between 1.5-1.7m/min, and the drilling depth should be controlled between 0.5-0.8. 2. The cushion plate used for drilling aluminum sheets requires a moderate hardness, uniform thickness, flatness, and a thickness difference of no more than 0.076mm. If the distribution of the cushion plate's softness and hardness is irregular, it is easy to get stuck in the drilling nozzle. If the cushion plate is uneven, it will cause the p

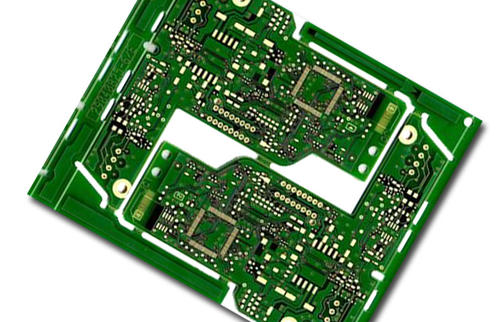

At present, there are four types of flexible circuits: single-sided, double-sided, multi-layer flexible boards, and rigid flexible boards. ① Single sided flexible board is the lowest cost printed board when it does not require high electrical performance. When wiring on one side, a single-sided flexible board should be selected. It has a layer of chemically etched conductive patterns, and the conductive pattern layer on the flexible insulation substrate surface is rolled copper foil. The insulation substrate can be polyimide, polyethylene terephthalate, aramid fiber ester, and polyvinyl chloride. ② Double sided flexible board is a conductive pattern made by etching one layer on each side of the insulating substrate film. Metallized holes connect the patterns on both sides of the insulating material to form a conductive path, in order to meet the design and functional requirements of flexibility. And the covering film can protect single and double-sided wires and indicate the posi

At present, 5G is booming, and with the arrival of the 5G era, PCB, as the mother of the electronic industry and the carrier of all components, occupies the largest proportion and benefits the PCB industry in this chain. The development of 5G cannot do without the construction of large-scale data centers, which will inevitably increase the number of servers. The development of servers cannot do without PCBs. Due to the huge traffic carried by data centers and the high requirements for transmission speed, the requirements for the number of layers and materials of PCBs will also become higher. In this case, the demand for high-end communication boards will be greatly increased. With the continuous advancement of 5G construction, due to the high-speed and high-frequency characteristics of 5G, the value of communication boards for a single base station will also be greatly increased, and the demand for communication boards in 5G base station construction will be further stimulated. F

1. Engineering design: The arrangement of interlayer semi cured sheets should correspond; Multi layer core boards and semi cured sheets should use the same supplier's products; The area of the outer C/S surface graphics should be as close as possible, and independent grids can be used; 2. Drying the board before cutting Generally, at 150 degrees Celsius for 6-10 hours, the moisture inside the board is eliminated to further solidify the resin completely and eliminate stress inside the board; Bake the board before cutting, whether it is the inner layer or both sides! 3. Attention should be paid to the warp and weft directions of the cured sheets before laminating the multi-layer board: The contraction ratio in the warp and weft directions is different. Before cutting and stacking the semi cured sheet, pay attention to distinguishing the warp and weft directions; When cutting the core board, attention should also be paid to the warp and weft directions; The general direction of th

1. Hot air leveling (tin spraying) Hot air leveling, also known as hot air solder leveling (commonly known as tin spraying), is a process of coating the surface of a PCB with molten tin (lead) solder and flattening it with heated compressed air, forming a coating layer that is not only resistant to copper oxidation but also provides good solderability. Hot air leveling forms copper tin intermetallic compounds at the junction of solder and copper. PCB should sink into the melted solder during hot air leveling; The wind knife blows out the liquid solder before it solidifies; The wind knife can minimize the crescent shape of the solder on the copper surface and prevent solder bridging. 2. Organic Solderability Protector (OSP) OSP is a process for surface treatment of copper foil on printed circuit boards (PCBs) that complies with RoHS instructions. OSP is the abbreviation for Organic Solderability Preservatives, which is translated as organic solder mask, also known as copper prote

1. Issues related to substrate processing: Especially for some thinner substrates (usually below 0.8mm), due to poor substrate rigidity, it is not suitable to use a brush machine to brush the board. This may not effectively remove the protective layer specially treated to prevent oxidation of the copper foil on the surface of the substrate during production and processing. Although this layer is thin and easy to remove by brushing, chemical treatment poses significant difficulties. Therefore, it is important to pay attention to control during production and processing to avoid poor bonding between the substrate copper foil and chemical copper, which may cause foaming on the surface of the substrate; When blackening is carried out on thin inner layers, there may also be problems such as poor blackening and browning, uneven color, and poor local blackening and browning. 2. The phenomenon of poor surface treatment caused by oil stains or other liquids contaminated with dust during

If you want to produce circuit boards that do not contain halogen elements, you need to start with the raw materials. According to the JPCA-ES-01-2003 standard, copper clad boards with chlorine (C1) and bromine (Br) content less than 0.09% Wt (weight ratio) are defined as halogen-free copper clad boards. (Meanwhile, the total amount of CI+Br is ≤ 0.15% [1500PPM]). So why ban brine? Halogens refer to halogen elements in the periodic table of chemical elements, including fluorine (F), chlorine (CL), bromine (Br), and iodine (1). At present, flame retardant substrates such as FR4 and CEM-3 are mostly brominated epoxy resins as flame retardants. In brominated epoxy resin, tetrabromobisphenol A, polybrominated biphenyls, polybrominated biphenyl ethers, and polybrominated diphenyl ethers are the main blocking fuels for copper clad laminates, with low cost and compatibility with epoxy resin. However, research by relevant institutions has shown that flame retardant materials containing ha

Inquiry Now