+86 755 2794 4155

+86 755 2794 4155  sales@knownpcb.com

sales@knownpcb.com

-

Shenzhen KNOWNPCB Technology Co., Ltd.

+86 755 2794 4155

+86 755 2794 4155  sales@knownpcb.com

sales@knownpcb.com

Have you noticed that now more and more of our lighting is using led lighting.What is LED? Compared to the traditional light bulbs, LEDs have lower power consumption, longer lifetime and higher energy efficiency. In the PCB industry,when we say LED PCB, it refers to the pcb used for LED lighting, if you are looking for a suitable LED PCB for your lighting system, this article may bring you something. WHAT ARE LEDS COMPOSED OF?LED is an initial light-emitting diode that produces light when an electric current passes through. LEDs typically have negative and positive electrodes, which generate light in the visible light region.The LEDS are glued to the PCB by soldering process and have electrical connections for lighting.Since light-emitting diodes dissipate a lot of heat when they are in use, when you are designing LED, the metal core is usually the best choice for LED PCB, it is because that it dissipates heat more faster. Among them, the metal material aluminum is the most widely used

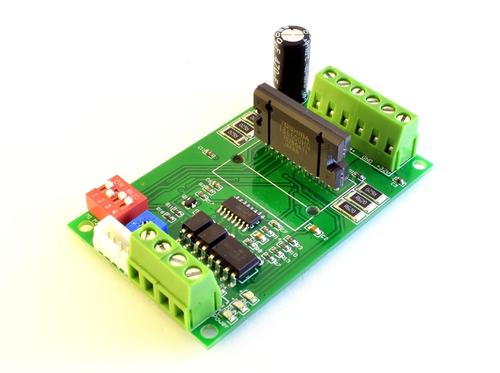

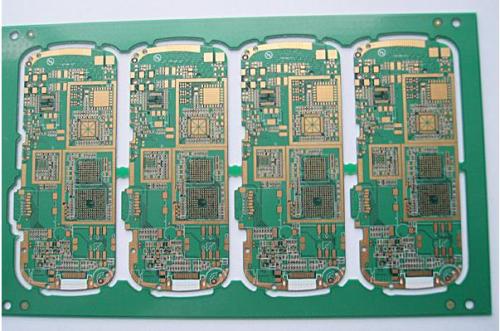

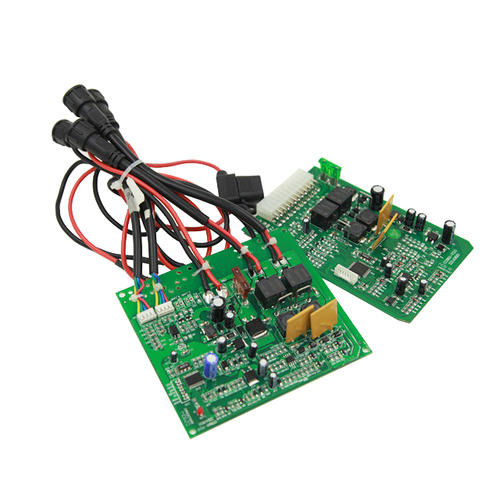

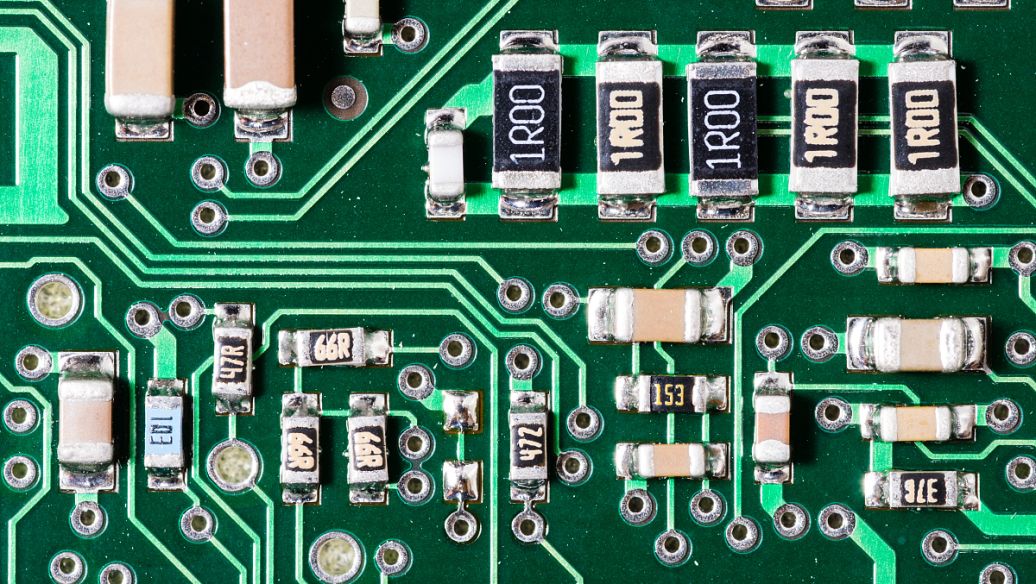

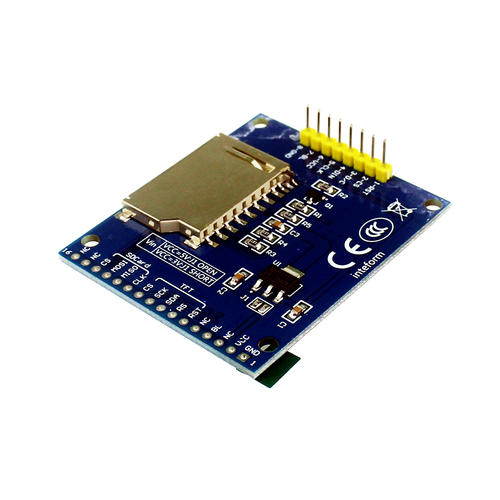

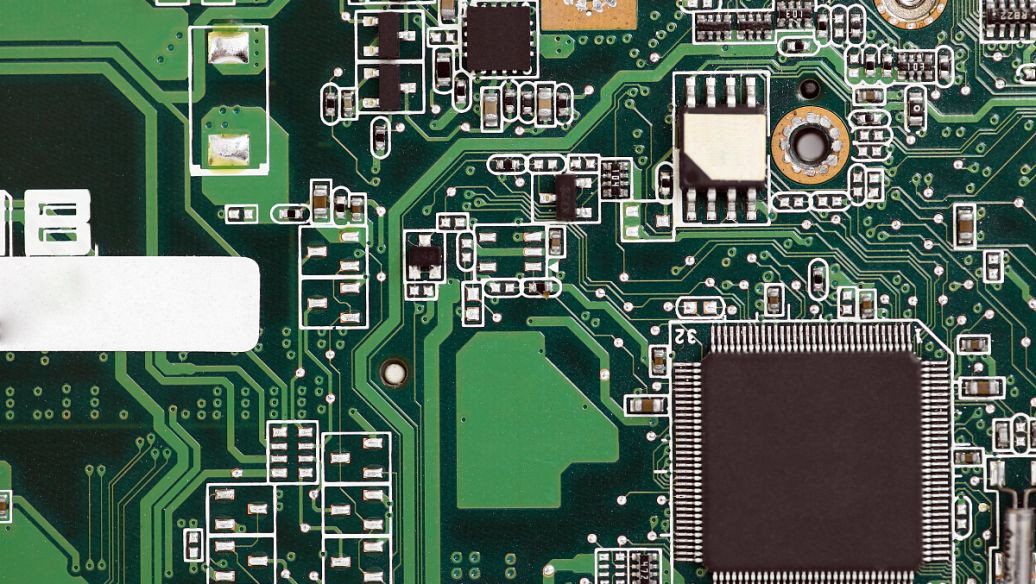

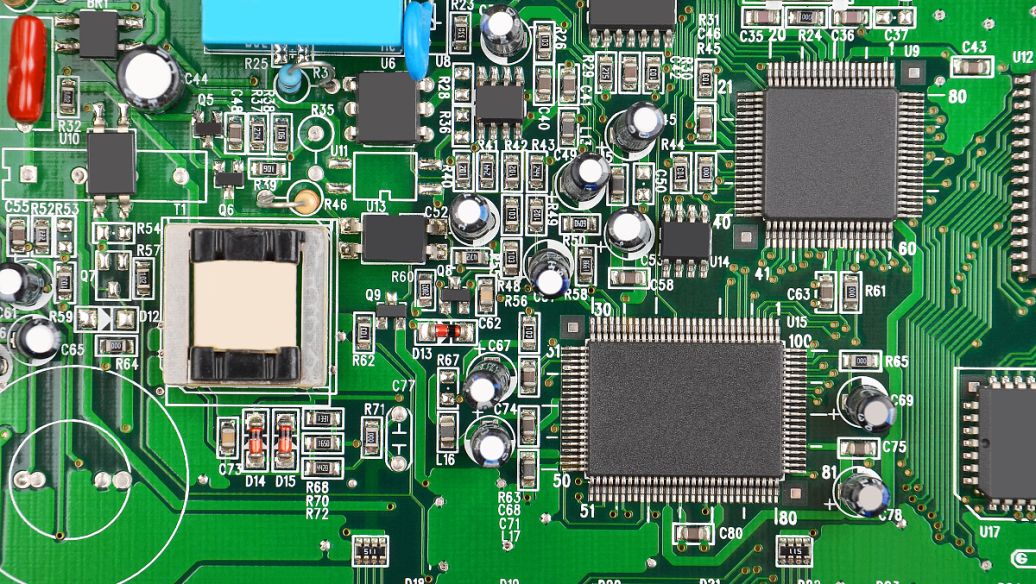

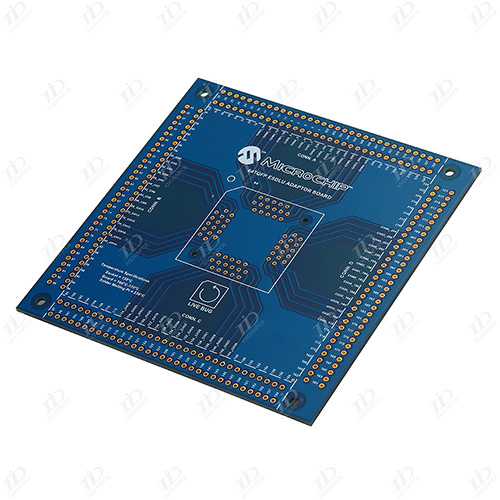

PCB (Printed Circuit Board), also known as Printed Circuit Board or Printed Circuit Board in Chinese, is an important electronic component that supports electronic components and provides electrical connections for electronic components. Due to its use of electronic printing technology, it is called a "printed" circuit board. The early 20th century to the late 1940s was the embryonic stage of the development of PCB substrate materials industry. Its development characteristics are mainly reflected in the emergence of a large number of resin, reinforcement materials, and insulation substrates used by professional PCB manufacturers for substrate materials during this period, and preliminary technological exploration has been made. All of these have created necessary conditions for the emergence and development of the most typical substrate material for printed circuit boards - copper-clad board. On the other hand, the mainstream PCB manufacturing technology, which uses metal foil etc

PCB (Printed Circuit Board), also known as Printed Circuit Board or Printed Circuit Board in Chinese, is an important electronic component that supports electronic components and provides electrical connections for electronic components. Due to its use of electronic printing technology, it is called a "printed" circuit board. The early 20th century to the late 1940s was the embryonic stage of the development of PCB substrate materials industry. Its development characteristics are mainly reflected in the emergence of a large number of resin, reinforcement materials, and insulation substrates used by professional PCB manufacturers for substrate materials during this period, and preliminary technological exploration has been made. All of these have created necessary conditions for the emergence and development of the most typical substrate material for printed circuit boards - copper-clad board. On the other hand, the mainstream PCB manufacturing technology, which uses metal foil etc

1. The multi-layer PCB board has good sampling quality and strong wear resistance. The surface of the PCB board sample is clearly and aesthetically pleasing, and can be marked with various logos, patterns, QR codes, and text. The patterns are directly engraved on the material, which highlights the wear resistance; 2. High machining accuracy. The minimum spot diameter of the laser beam emitted by the laser can reach 10um (UV laser) after being focused, which is of great help in processing complex graphics and precision machining; 3. High efficiency, simple operation, and cost reduction. Users only need to set the parameters on the computer to directly mark the material surface, which can be completed in just a few seconds to more than ten seconds; 4. Non destructive marking. Laser marking adopts non-contact processing, and the laser head does not need to contact the surface of the material, so there is no need to consider damage to the material; 5. Wide range of use, safe and en

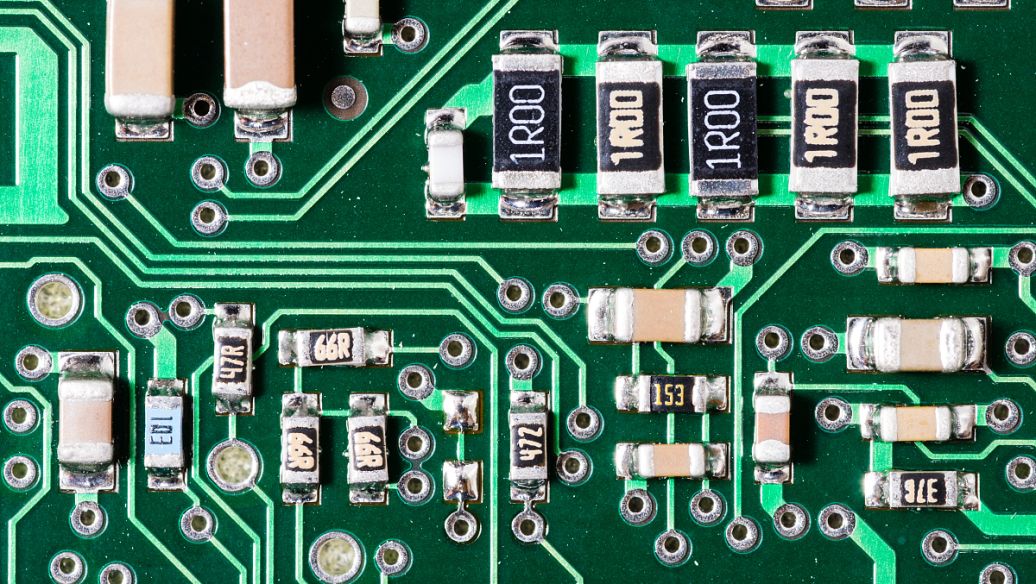

1. Substrate ★ FR4: Glass cloth epoxy resin copper-clad foil plate (Tg: 130 °). ★ CEM-1: Paper core glass cloth surface - epoxy resin copper-clad foil board. ★ 94V0: Flame retardant cardboard. ★ Aluminum substrate: Thermal conductivity coefficient of 100. 2. Copper foil: 99.9% or more electrolytic copper, surface copper foil thickness of finished product: 18 μ M (H/HOZ), 35 μ M (1OZ), 70 μ M (2OZ). 3. Plate thickness: ★ Thickness of single and double-sided boards: 0.4mm, 0.6mm, 0.8mm, 1.0mm, 1.2mm, 1.6mm, 2.0mm, 2.5mm The minimum thickness of multi-layer printed boards: 4 layers ≥ 0.6mm, 6 layers ≥ 1.0mm, and 8 layers ≥ 1.6mm, with a finished board thickness tolerance of ± 10%.

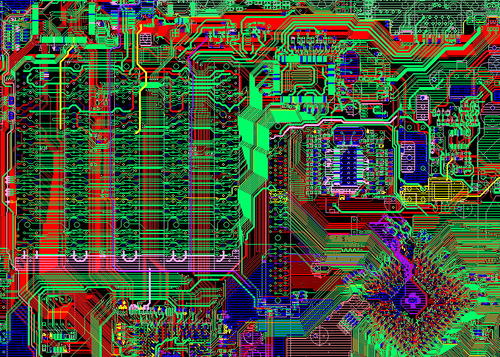

1. The less bending the leads between the pins of high-speed electronic devices, the better. It is best to use full straight leads for high-frequency circuit wiring, and if a bend is needed, a 45 degree bend or arc bend can be used. This requirement is only used to improve the bonding strength of copper foil in low-frequency circuits, while in high-frequency circuits, meeting this requirement can reduce the external emission and mutual coupling of high-frequency signals. 2. The less interlayer alternation between the pins of high-frequency circuit devices, the better. The so-called "less interlayer alternation of the leads, the better" refers to the use of fewer via (Via) during the component connection process. A through-hole can bring about a distributed capacitance of about 0.5pF, reducing the number of through-holes can significantly improve speed and reduce the possibility of data errors. 3. The shorter the lead between the pins of high-frequency circuit devices, the better.

The resistance encountered during the propagation of high-frequency signals or electromagnetic waves in electronic device transmission signal lines is called "impedance". Why do some boards require impedance during the production process, and what are the advantages of impedance PCB circuit boards! 1. It is necessary to consider the installation of electronic components through plug connections, and later SMT patch connections also need to consider issues such as conductivity and signal transmission performance, so the lower the impedance, the better. 2. During the production process, the materials used must have low electrical resistivity to ensure that the overall impedance value of the circuit board meets the product quality requirements and can operate normally. 3. PCB tin plating is the most common problem in the production of the entire circuit board, and it is a key link that affects impedance; Its biggest defects are easy oxidation or deliquescence, poor solderability, mak

The origin of PCB circuit board printing in China probably dates back to the middle and late 1990s. The research on automatic optical detection systems for circuit board printing defects is still at a relatively early level. With the continuous maturity of process technology in the later stage, there has been progress in express delivery in the field of printed circuit boards. With the rapid development of the electronics industry, the application scope of circuit boards has also increased, So how do we distinguish the quality and sincerity of finished circuit boards! 1: Board thickness control standards: Different factories have limited printable process capabilities when printing circuit boards. The standard accuracy of the manufacturer can be determined based on the board thickness. The smaller the control tolerance, the stronger the printing ability, while the larger the control tolerance, the smaller the printing ability. 2: The glossiness of the solder mask color on the boa

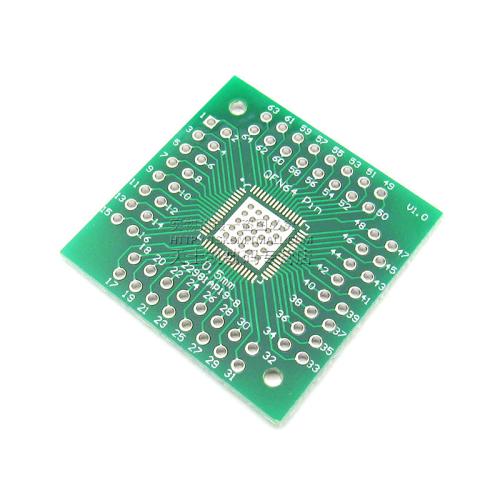

The shape of circuit board pads can be divided into 7 categories: 1. Square solder pads: commonly used when the components on a printed circuit board are large but few, and the printed wires are simple. 2. Circular solder pads: widely used in single and double-sided printed boards with regular component arrangement. 3. Island pad: The connection between pads is integrated and is commonly used in vertical irregular arrangement installation. 4. Teardrop solder pads: often used when connecting thin wires, commonly used in high-frequency circuits. 5. Polygonal pads: Used to distinguish pads with similar outer diameters but different apertures, making it easy to process and assemble. 6. Elliptical pad: This type of pad has sufficient area to enhance peel resistance and is commonly used in dual inline devices. 7. Open solder pads: commonly used to ensure that the holes of manually repaired solder pads are not sealed by solder after wave soldering.

1. The minimum diameter on one side of all solder pads shall not be less than 0.25mm, and the maximum diameter of the entire solder pad shall not exceed three times the aperture of the component. 2. Efforts should be made to ensure that the distance between the edges of two solder pads is greater than 0.4mm. 3. In cases of dense wiring, it is recommended to use elliptical and elongated solder pads. 4. For plug-in components, in order to avoid copper foil breakage during welding, the single-sided connecting plate should be completely covered with copper foil, and the minimum requirement for double panels should be to fill in tears. 5. All machine insertion parts should be designed as drip solder pads along the bending direction to ensure full solder joints at the bending position. 6. Daisy shaped solder pads should be used on large-area copper sheets to avoid virtual soldering.

(1) Protective post-treatment Except for chrome plating, all other protective coatings used as surface coatings must undergo appropriate post-treatment to maintain or enhance their protective performance. The most commonly used post-processing method is passivation. For those with high protection requirements, surface coating treatment should be carried out, such as glossy coating treatment. From the perspective of environmental protection and cost, water-based transparent coating can be used. (2) Decorative post-treatment Decorative post-treatment is a common treatment process in non-metallic electroplating. For example, imitation gold, imitation silver, imitation antique copper plating, brushing, coloring or dyeing, and other artistic treatments. Most of these treatments also require the surface to be coated with transparent gloss coating. Sometimes it is necessary to use colored transparent coatings, such as imitation gold, red, green, purple and other colors. (3) Functional

1、 Decanting method Decanting method is actually a filtration method, which is a physical method in the wastewater treatment of PCB board industry. The flushing water containing copper shavings discharged by the deburring machine can be filtered and removed after being treated by a decanter. The effluent filtered by the decanter can be reused as cleaning water from the burr machine. 2、 Chemical method Chemical methods include redox method and chemical precipitation method. The oxidation-reduction method is the use of oxidants or reducing agents to convert harmful substances into harmless or easily precipitated substances. The cyanide containing wastewater and chromium containing wastewater in circuit boards are often treated using the oxidation-reduction method, as explained later. Chemical precipitation method is the use of one or several chemical agents to convert harmful substances into easily separable precipitates or precipitates. There are various chemical agents used for

1. The solderability of circuit board holes affects welding quality Poor solderability of circuit board holes will result in virtual soldering defects, affecting the parameters of components in the circuit, leading to unstable conduction of multi-layer board components and inner wires, and causing the entire circuit function to fail. The so-called weldability refers to the property of the metal surface being wetted by molten solder, that is, the formation of a relatively uniform and continuous smooth attached film on the metal surface where the solder is located. The main factors affecting the solderability of printed circuit boards are: (1) the composition of the solder and the properties of the soldered material. Solder is an important component of the welding chemical treatment process, which is composed of chemical materials containing flux. The commonly used low melting point eutectic metals are Sn-Pb or Sn-Pb-Ag. The impurity content should be controlled in a certain proport

PCB wastewater is polychlorinated biphenyl wastewater, which is a type of wastewater in the printing industry and circuit board factories. Nowadays, the world produces 300 million to 400 million tons of toxic and harmful chemical waste annually, among which persistent organic pollutants (POPs) are of great ecological harm and the most widely spread on Earth. In addition, PCB wastewater is divided into cleaning wastewater, ink wastewater, complexation wastewater, concentrated acid wastewater, concentrated alkali wastewater, etc. The production of printed circuit boards (PCBs) requires a large amount of water, and there are many types of pollutants in the wastewater with complex components. Reasonable classification, collection, and treatment of wastewater based on the characteristics of different PCB manufacturers are key to ensuring that wastewater treatment meets standards. For the treatment of wastewater in the PCB board industry, there are chemical methods (chemical precipitatio

Poor solderability of circuit board holes will result in virtual soldering defects, affecting the parameters of components in the circuit, leading to unstable conduction of multi-layer board components and inner wires, and causing the entire circuit function to fail. The so-called weldability refers to the property of the metal surface being wetted by molten solder, that is, the formation of a relatively uniform and continuous smooth attached film on the metal surface where the solder is located. The main factors affecting the solderability of printed circuit boards are: (1) the composition of the solder and the properties of the soldered material. Solder is an important component of the welding chemical treatment process, which is composed of chemical materials containing flux. The commonly used low melting point eutectic metals are Sn-Pb or Sn-Pb-Ag. The impurity content should be controlled in a certain proportion to prevent the oxide produced by impurities from being dissolved

The circuit board and components undergo warping during the welding process, resulting in defects such as virtual soldering and short circuits due to stress deformation. Warping is often caused by temperature imbalance between the upper and lower parts of a circuit board. For large PCBs, the weight of the board itself can also cause warping. A regular PBGA device is about 0.5mm away from the printed circuit board. If the device on the circuit board is large, as the circuit board cools down and returns to its normal shape, the solder joints will be under stress for a long time. If the device is raised by 0.1mm, it is enough to cause a virtual solder open circuit. In terms of layout, when the circuit board size is too large, although welding is easier to control, the printed lines are longer, the impedance increases, the noise resistance decreases, and the cost increases; If it is too small, the heat dissipation will decrease, and welding will be difficult to control, making it easy

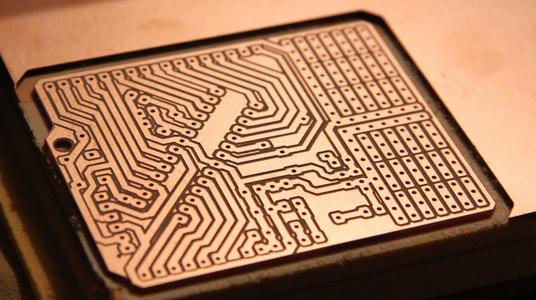

Introduce the relevant content and situation of printed circuit boards to help everyone improve their understanding. Let's read the following content together with the editor. Printed circuit boards (PCBs) are convenient thin sheets used to accommodate interconnected electrical components in a simple, convenient, and economical manner. They are used as physical supports for installing and connecting different electrical components. The PCB is made of glass fiber, composite epoxy resin or any other composite material, and has a metal coated surface. They have etching made of metals and acids to create circuits through different integrated circuits (ICs) and other components on circuit boards. Solder connects ICs and other components to the surface of the circuit board. The copper tracks in the circuit board reduce the possibility of short circuits, misalignment, or misaligned wires. In this way, all components are firmly fixed to the circuit board without the need for complex wirin

The so-called copper coating refers to using the idle space on the PCB as a reference plane, and then filling it with solid copper. These copper areas are also known as copper filling. Copper coating can be divided into large-area copper coating and grid copper coating. Next, let professional PCB manufacturers provide you with a detailed understanding of the basic knowledge of PCB circuit board copper coating: 1、 Precautions for copper coating: 1. Single point connection in different locations: connected through a 0 ohm resistor, magnetic bead, or inductor. 2. The copper coating near the crystal oscillator is used as a high-frequency emission source in the circuit. The crystal oscillator should be surrounded by copper coating, and then the outer shell of the crystal oscillator should be grounded separately. 2、 What are the benefits of copper coating? 1. Copper coating can reduce ground wire impedance and improve anti-interference ability; 2. Reduce voltage drop and improve po

In the field of PCB, there are often many English terms that industry insiders may find difficult to fully recognize. How much do you know about PCB terminology? Let me introduce some commonly used terms in the PCB field to you: 1. FR4 In most cases, the glass fiber substrate for PCBs generally refers to the material "FR4". The solid material "FR4" gives PCB hardness and thickness. Some cheap PCBs are made of materials such as epoxy resin or phenol, lacking the durability of FR4, but they are much cheaper. Phenolic substances have a lower thermal decomposition temperature, and excessive welding time can lead to their decomposition and carbonization, and emit unpleasant odors. 2. Copper The thin copper foil layer on a PCB is pressed onto the substrate through heat and adhesive during production. On double-sided boards, copper foil is pressed onto both sides of the substrate. When we mention "double-sided board" or "two-layer board", we refer to two layers of copper foil on a th

On PCBs, nickel is used as a substrate coating for precious and base metals. The deposition layer of low stress nickel on PCB is usually prepared using modified Watt nickel plating solution and some amino sulfonic acid nickel plating solution with stress reducing additives. What are the common problems encountered when using PCB nickel plating solution, as analyzed by CITIC Huawei? 1、 Temperature - Different nickel processes use different plating bath temperatures. In nickel plating solutions with higher temperatures, the obtained nickel coating has low internal stress and good ductility. The general operating temperature is maintained at 55-60 degrees Celsius. If the temperature is too high, nickel salt hydrolysis will occur, causing pinholes in the coating and reducing cathodic polarization. 2、 PH value - The pH value of nickel plating electrolyte has a significant impact on the performance of the coating and electrolyte. The pH value of PCB nickel plating electrolyte is genera

In PCB sampling, nickel is used as a substrate coating for precious and base metals. For some surfaces with heavy load wear, using nickel as the gold substrate coating can greatly improve wear resistance. When used as a barrier layer, nickel can effectively prevent the diffusion between copper and other metals. Next, CITIC Huawei will explain the causes and solutions of PCB nickel plating process faults: 1、 Ma Keng: Ma Keng is the result of organic pollution; If the stirring is poor, bubbles cannot be expelled and pits will form. Large pits usually indicate oil contamination, and wetting agents can be used to reduce their impact. Small pits are called pinholes, which can be caused by poor treatment, metal impurities, low boric acid content, and low plating temperature. Bath maintenance and process control are key, and anti pinhole agents should be used as process stabilizers to supplement. 2、 Roughness and burrs: Roughness indicates that the solution is dirty, which can be correc

Inquiry Now